CC-218 Diversity

2025/08/06 created

2025/10/02 updated

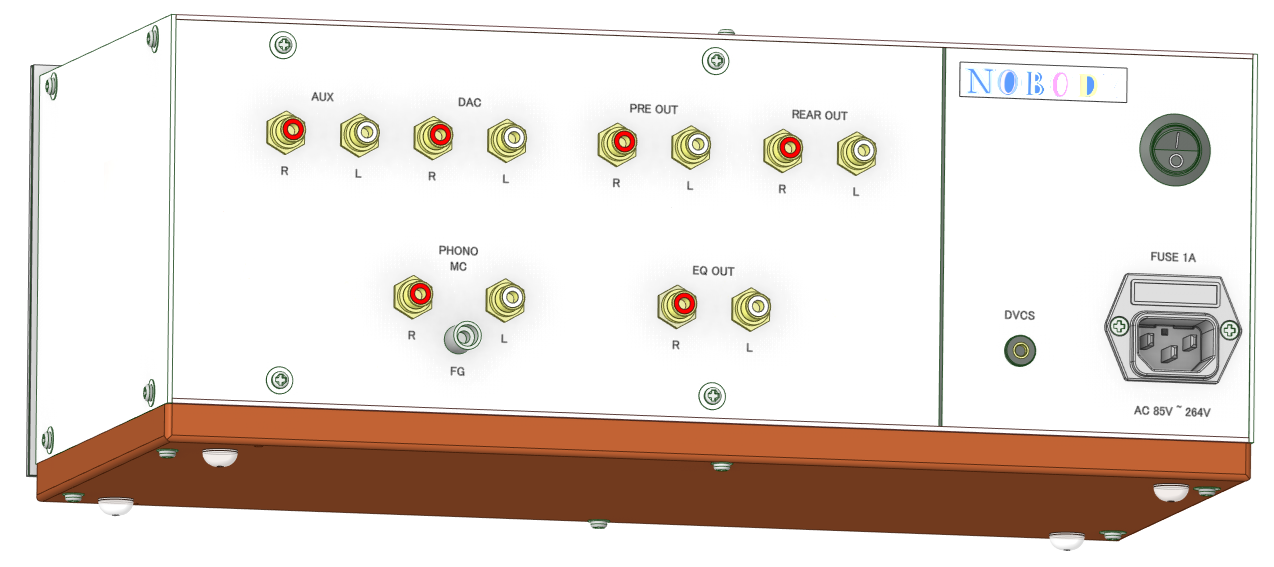

Stereo Control Center (Preamplifer)

One and only preamp that meets all of my personal requirements!

| Features | Electronic volume using TI PGA2310, Selector using shunt switching, Phono EQ for MC cartridge only, Matrix circuitry compatible with Sansui QS4 (4-channel stereo)、Detachable front panels, IR remote, Controlable by PC, DVCS support. |

|---|---|

| Outline Specifications | Inputs: PHONO(MC only), LINE IN x2 (DAC, AUX). Output: PRE OUT x1, REAR OUT, EQ OUT. Maximum gain: +3dB. Frequency range: DC-160kHz (-3dB). |

| Dimension | Dimension: 360(W) x 142(H) x 190(D) mm (not including protrusions). Weight: 4.5kg (not including the power cord). |

| Cost | 106,422 JPY |

| History | Design started in May, 2023. Completed in May, 2025. Being used in Gaudi II. |

Contents:

Concept

Specifications

Design

Appearance Design

Mechanical Design

Layout and Wiring Design

Circuit Design

PCB Design

Firmware Design

Building

Measurements and Improvements

My Own Review

Summing-up

Concept

This is the preamplifier to be used in Gaudi Ver. 3.0. I named it the “Control

Center” because it has the capability to control a crossover network (hereafter

referred to as the “Xover”) and the power amplifier via the DVCS (which

I will explain later).

For me, this is my fifth self-built preamplifier (or the sixth if you count

the MV-217 as a preamplifier). Based on my past experiences, I have learned

many things and, as a result, have formed my own ideal vision. In this

project, I aimed to create my ideal preamplifier by bringing together all

of my knowledge and skills.

Top priorities in design are as follows:

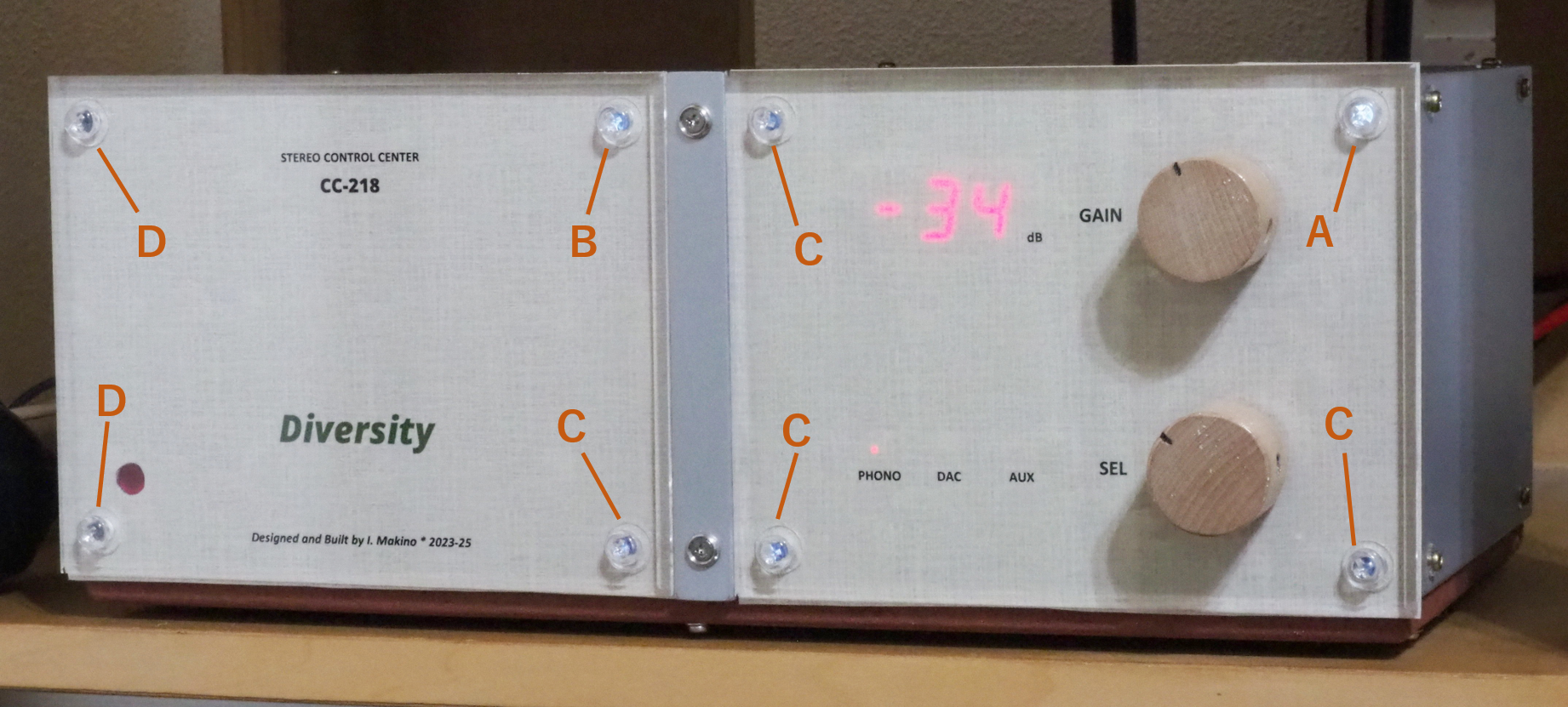

- (1) Good appearance that fits with my taste and the interior of the room

- This is a concept carried over from my previous work, the MV-217 X'tal. With the CC-218, I took this idea even further by making the front panel detachable. Since the appearance can be easily changed, it allows for applications such as changing the look to match the seasons.

- (2) Maintenance-free for 25 years

- By making the selector and volume contactless and using a sealed enclosure, the initial performance can be maintained over a long period of time. Components that deteriorate quickly with age, such as vacuum tubes, are not used.

- (3) DVCS support

- DVCS (Distributed Volume Control System) is a technology I developed myself. It is a system in which the volume control interface is built into the preamplifier, while the actual volume control circuitry is housed inside the power amplifier or the Xover. The aim is to improve the overall system’s SNR and dynamic range.

- (4) PCB

- Since electronic volume control and a digital display are used, incorporating an MCU (Microcontroller Unit) is essential. To miniaturize the control board equipped with the MCU, stabilize its operation, and reduce unwanted emissions, a PCB (Printed Circuit Board) is employed. Even for implementing the analog circuitry, using a PCB has advantages, such as stabilizing the ground potential and preventing crosstalk between signals.

- (5) Four-channel stereo

- This is one of my personal requirements. I own several QS4 records, but I have never listened to them in four-channel. For many years, I have wanted to hear their original sound.

- (6) Console feature

- By connecting CC-218 to a PC and running a terminal software application such as Tera Term on the PC, CC-218 can send status information (such as the internal state of the device or events occurring within the device) to be displayed on the application’s screen. In addition, commands can be sent from the application to change CC-218’s settings or execute its self-diagnostic program. I refer to this type of functionality as the “console feature,” and I call the PC running the terminal software the “Console.”

Nickname and Theme Music

The nickname is Diversity.

This work includes circuits operated under microcontroller control, such

as the electronic volume, as well as traditional circuits like a phono

equalizer (phono EQ), and even includes a feature of 4-ch stereo, a function

already forgotten by the general public. In addition to pursuing electrical

performance, attention has also been given to appearance and usability.

Since this work is packed with a variety of functions, it has been named

“Diversity.” These days, this word is often used in a moral or ethical

sense, but the name of this work carries no such moral meaning.

I chose Samba de Orfeu by the Ted Sommer Orchestra (LP, Ted Sommer Orchestra,

Percussive Mariachi, Solid State SS-18012) as the theme music. It’s a crossover piece that

blends jazz, Latin, samba, bossa nova, and mariachi — traditional Mexican

music.

I first heard this record when I was only ten years old, and the powerful

impression it made on me drew me deeply into the worlds of music and audio.

It’s been a lifelong favorite ever since.

--- Samba de Orfeu (TedSommer_SambaDeOrfeu_50sec.mp3) ---

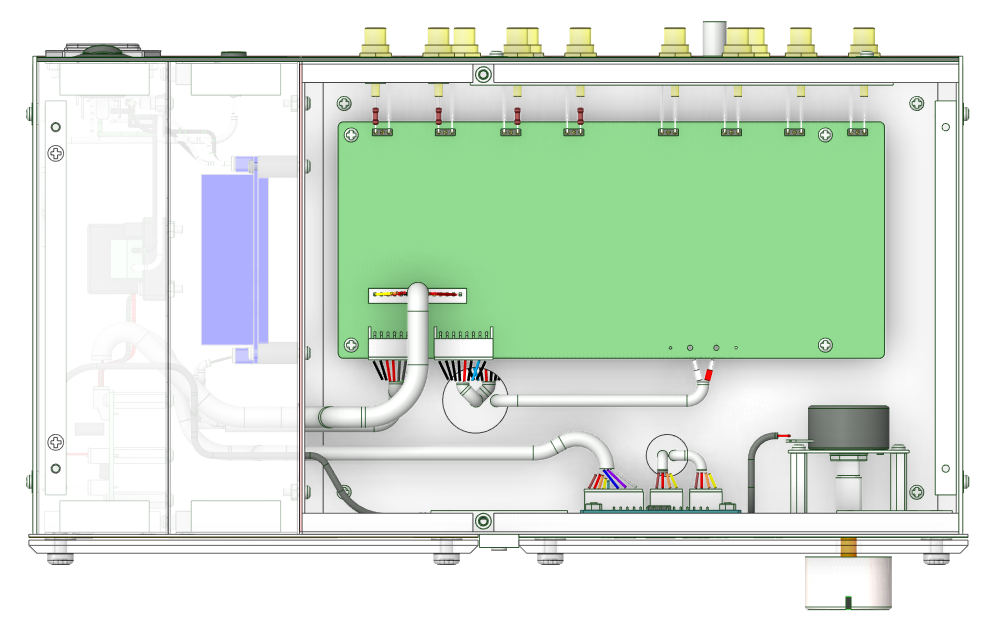

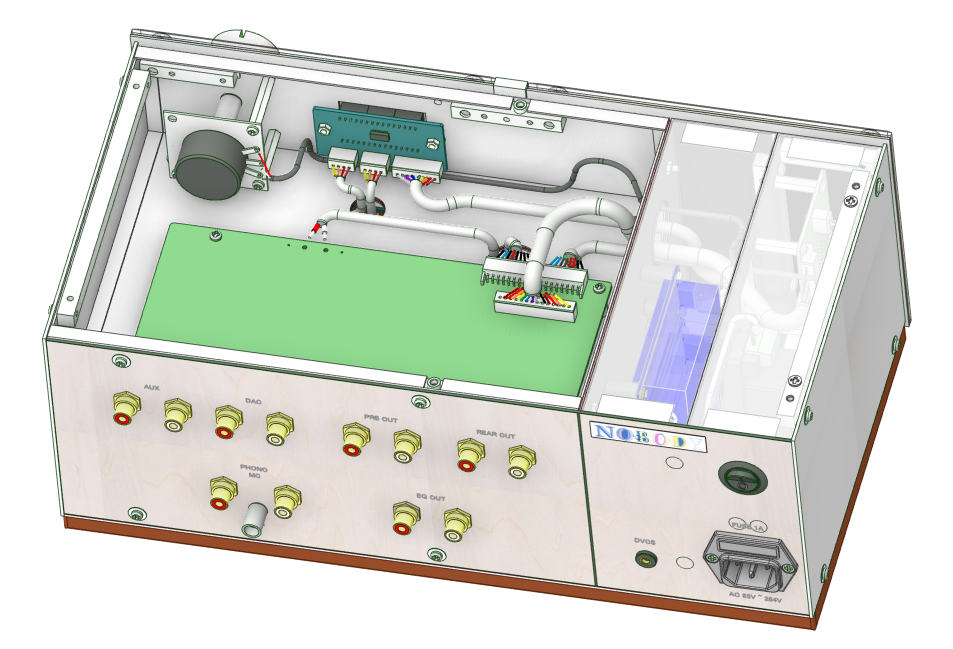

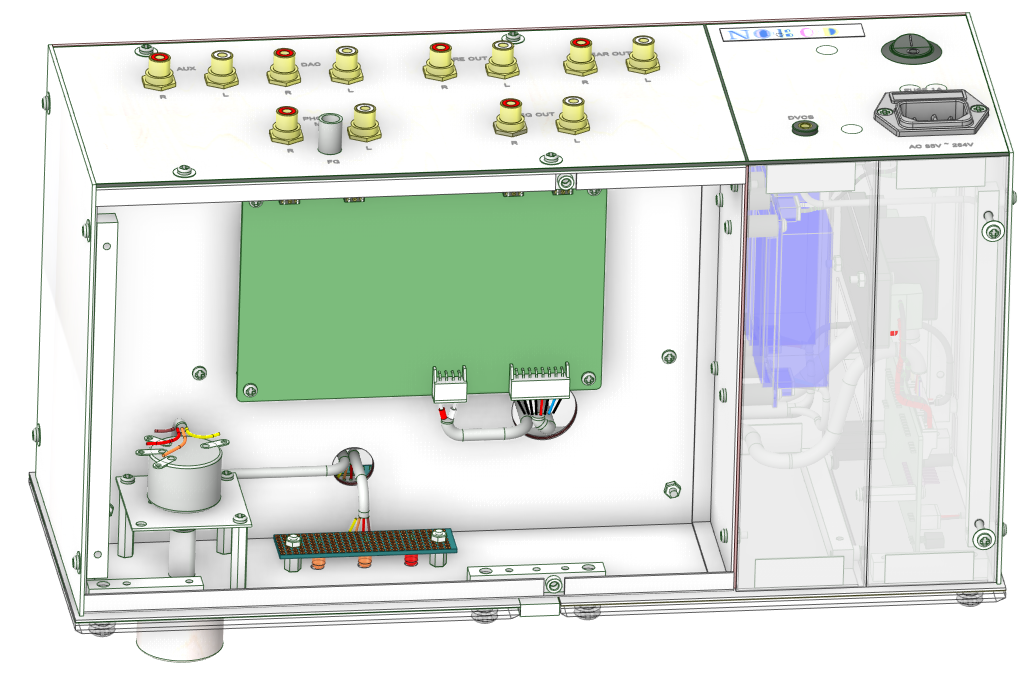

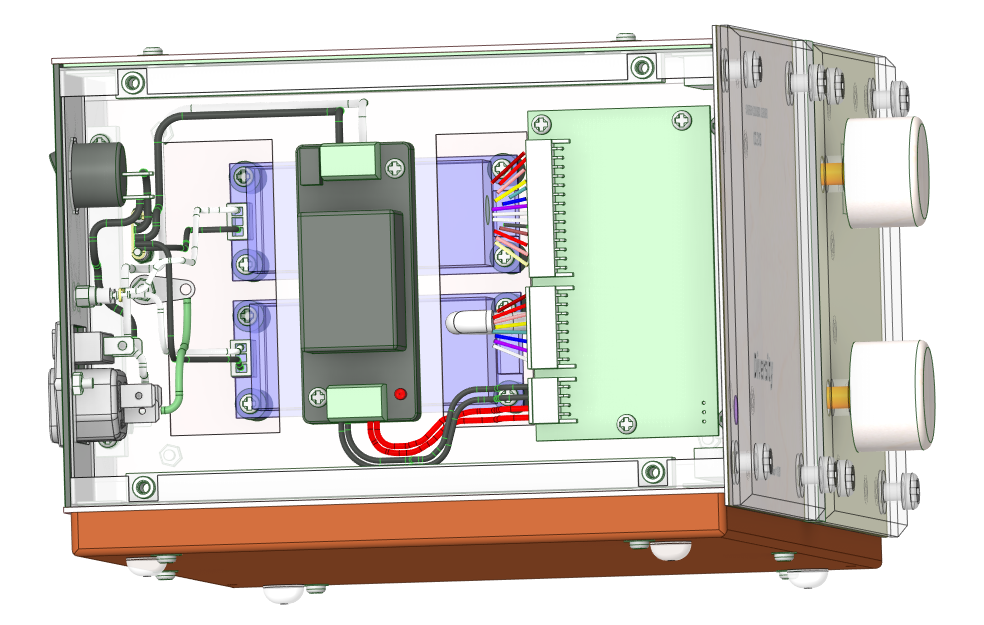

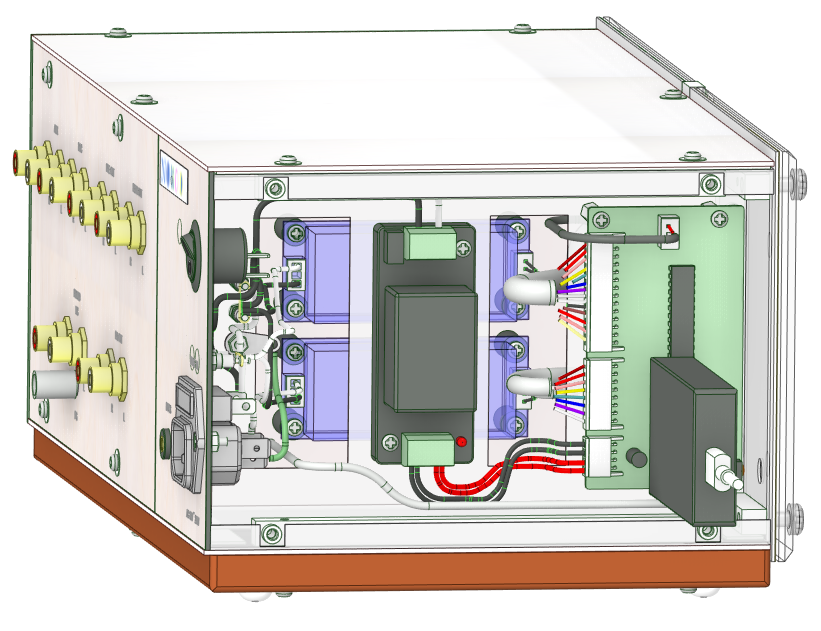

Rendering

Specifications

Hardware Spec

| Inputs | PHONO (MC only), LINE x2 (DAC, AUX). |

| PHONO input | Input impedance: 100 ohm, Max input level: 13mV, Connector:Gold-plated RCA jacks. |

| LINE inputs | Input impedance: 22k ohm, Max input level: 8V (at gain =< 0dB), Connector: Gold-plated RCA jacks. |

| Outputs | PRE OUT, REAR OUT, EQ OUT. |

| PRE OUT, REAR OUT | Output impedance: 47 ohm, Load impedance: 600 ohm or higher. Maximum output level: 8V (600 ohm), Connector: Gold-plated RCA jacks. |

| EQ OUT | Output impedance: 47 ohm. Load impedance:600 ohm or higher, Max output level: 10V (600 ohm). Connector: Gold-plated RCA jacks. |

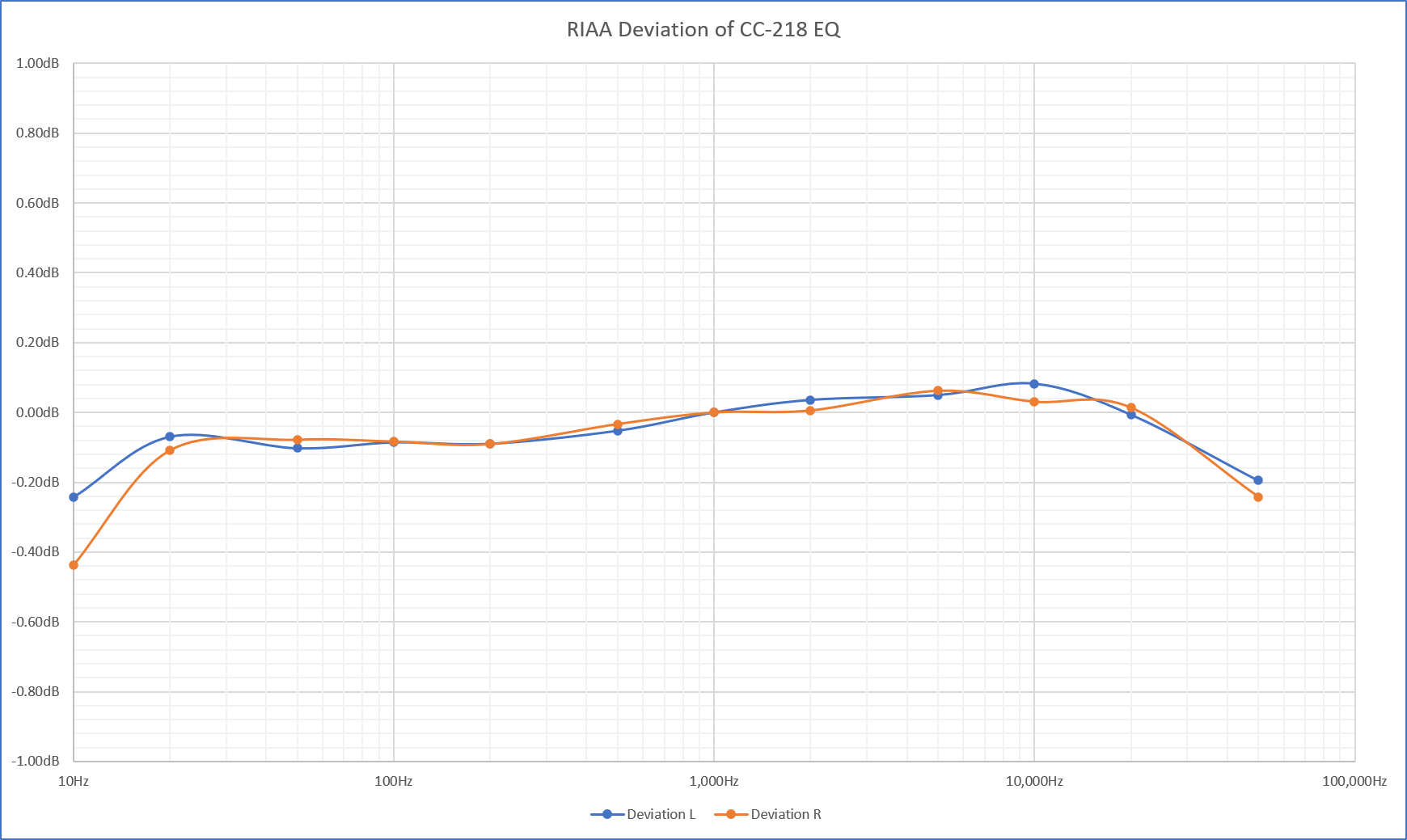

| PHONO EQ | RIAA deviation: +/-0.1dB (20Hz~20kHz). Channel deviation: +/-0.1dB (20Hz~20kHz). |

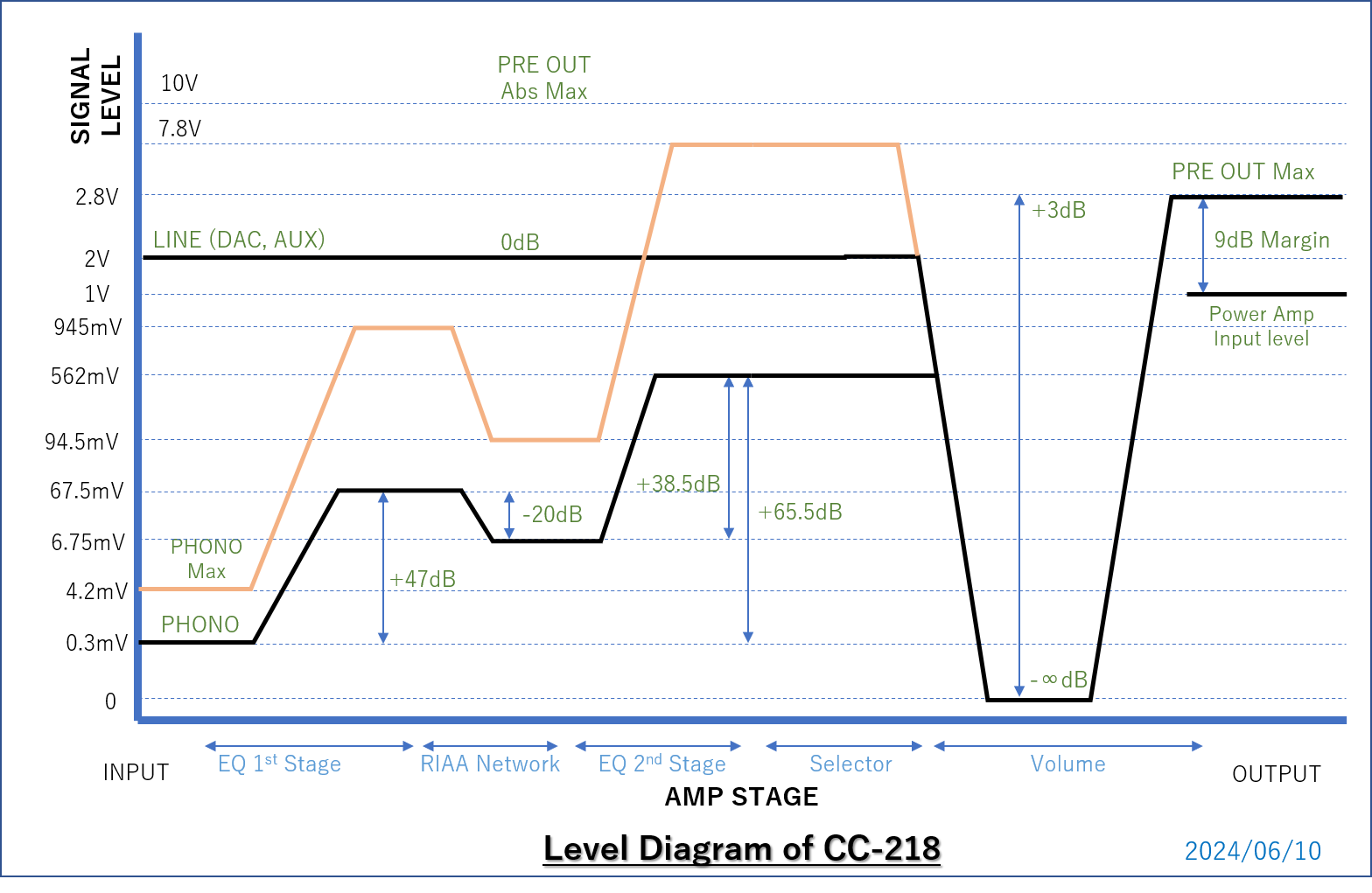

| Gain | PHONO: +66dB (1kHz). LINE: -∞dB、-60dB ~ +3dB. |

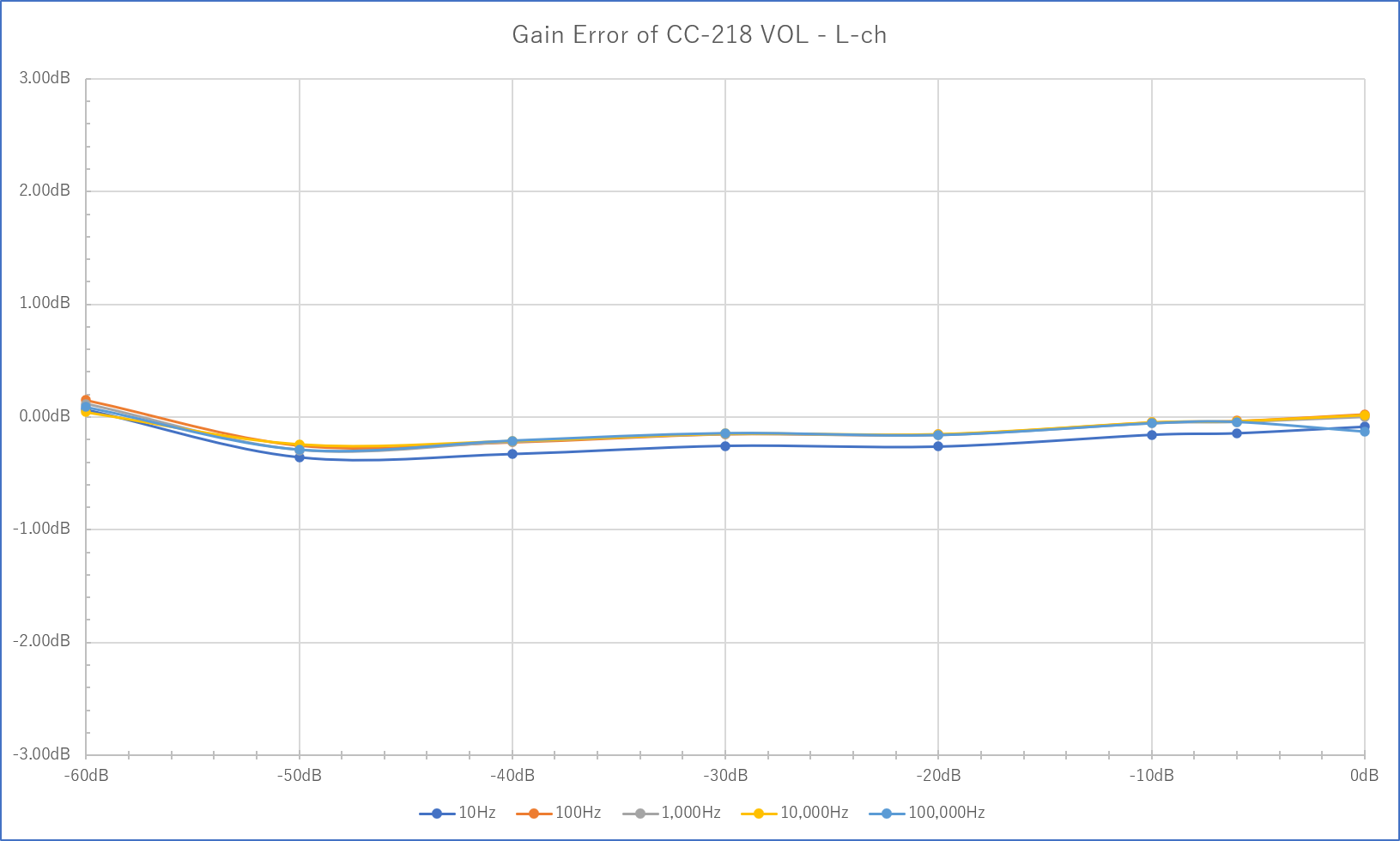

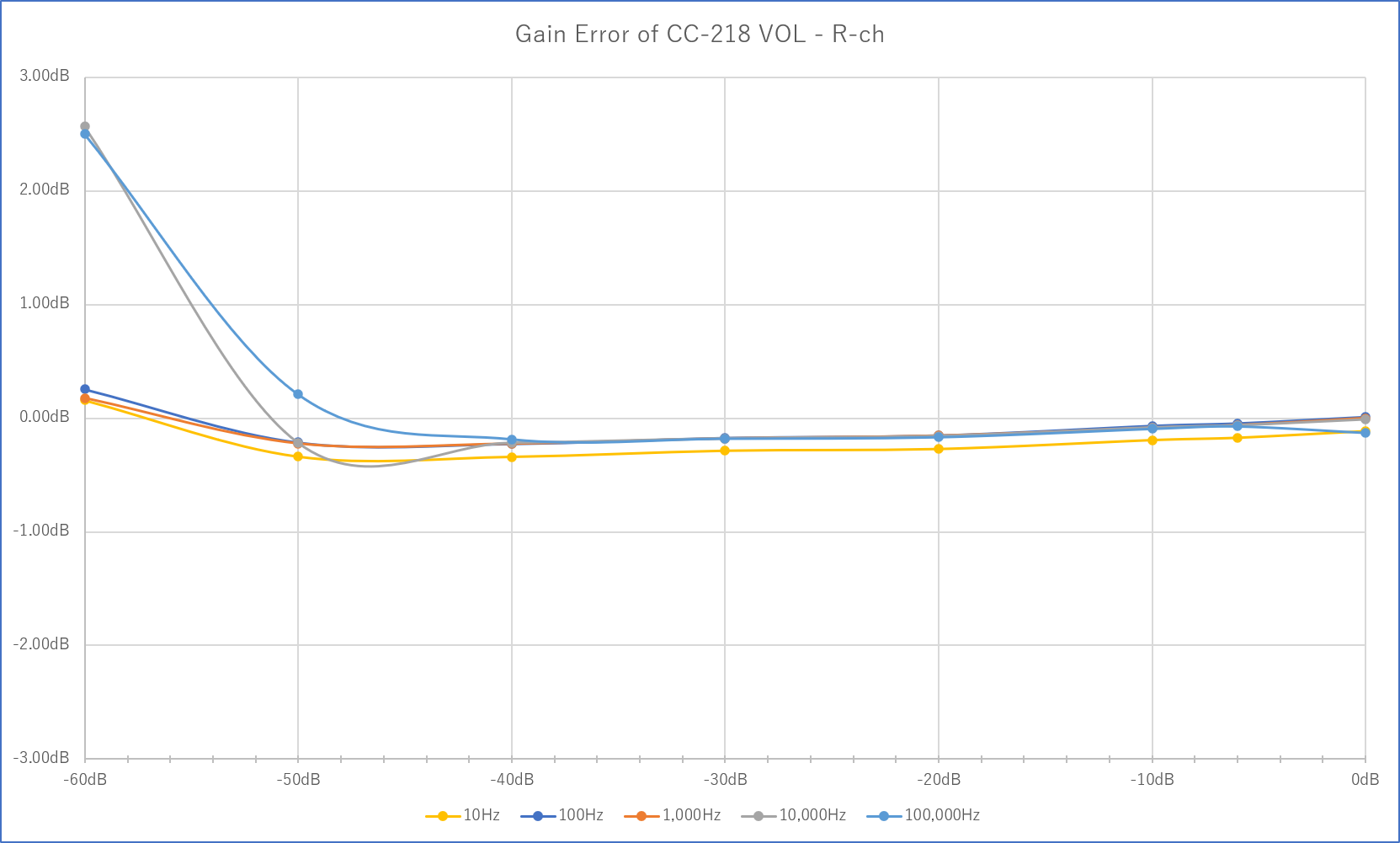

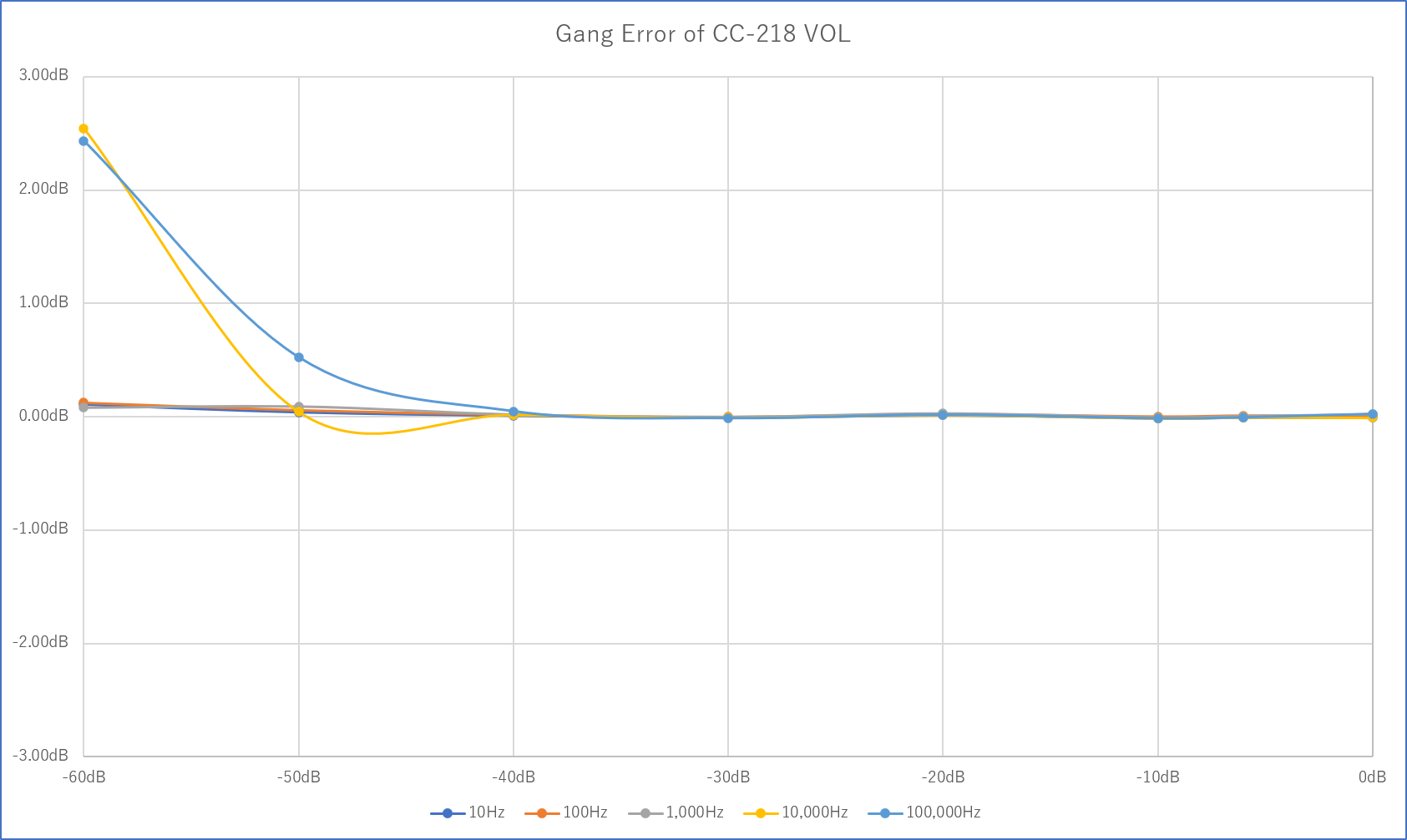

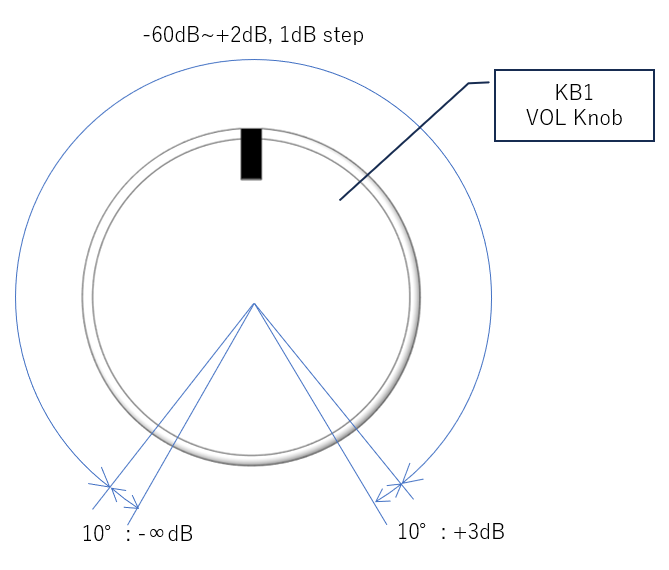

| Gain control | Panel operation: -∞dB, -60dB ~ +3dB, 1dB step. Remote control: -∞dB, -95.5dB ~ +10dB, 0.5dB step. Presets (remote): -40dB, -35dB, -30dB, ..., 0dB (5dB step). Gang error: +/-0.1dB or less. Default value: Calculated from the position of VOL (volume) knob. VOL knob rotation range: 300 deg. |

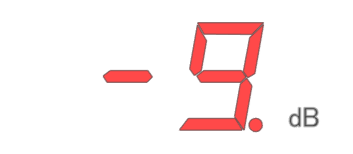

| Display of gain | Gain is displayed in dB. Display: 2-digit, 7-segment LEDs. 0.5dB (fraction) is indicated by decimal point only. '-' indicates -∞dB. Intensity: 7 steps (adjusted by remote). Display mode: 4 modes (described later) (switched by remote). |

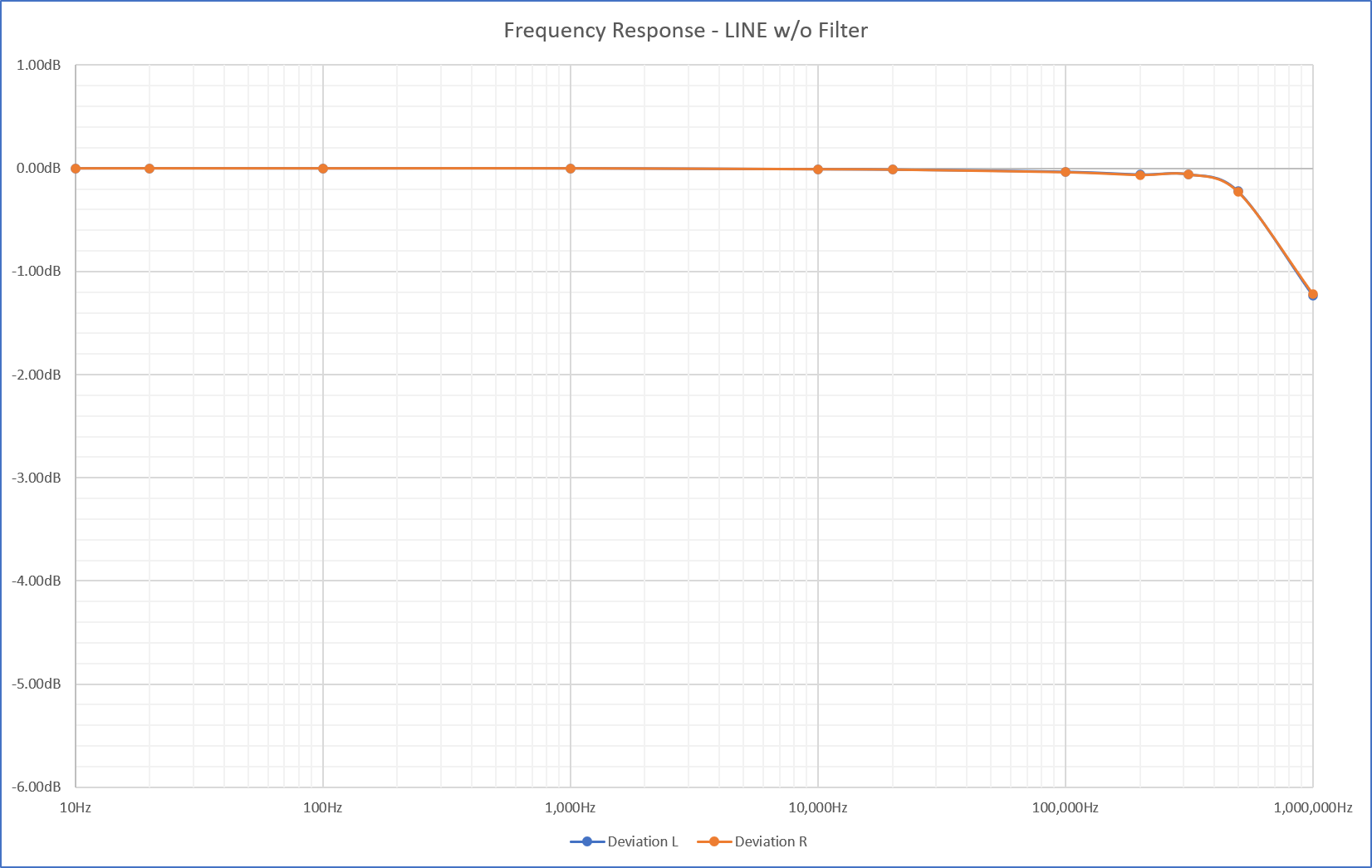

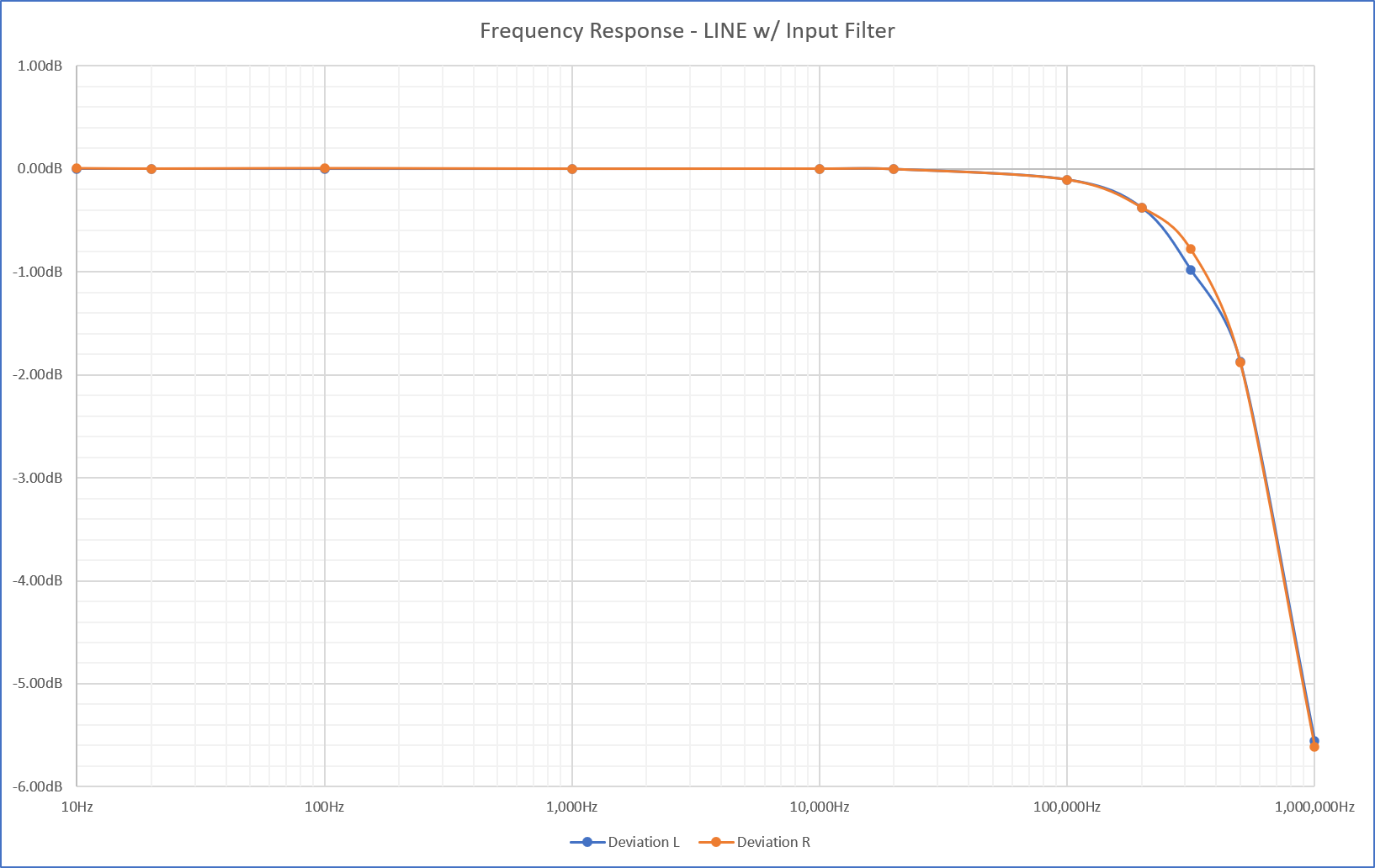

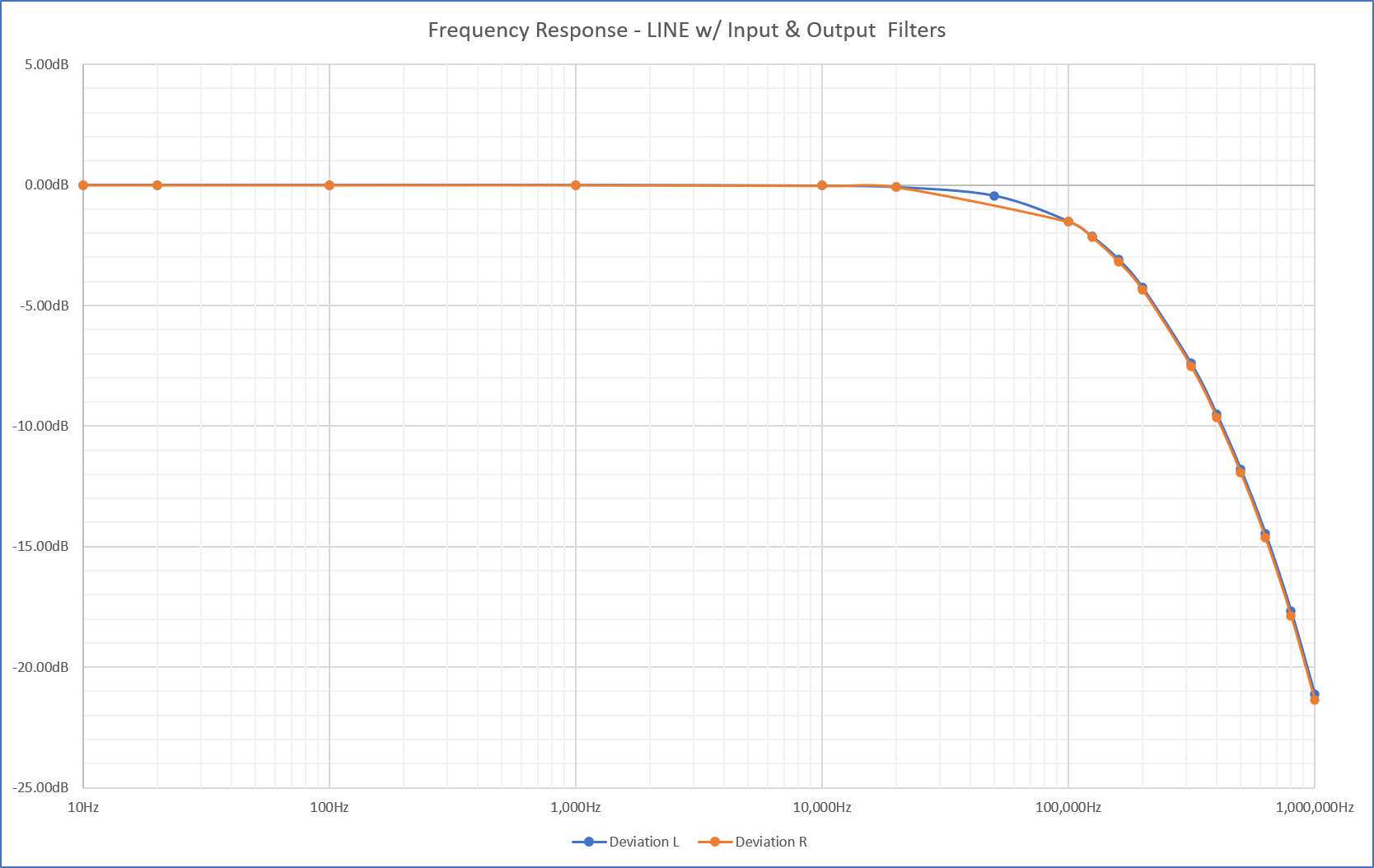

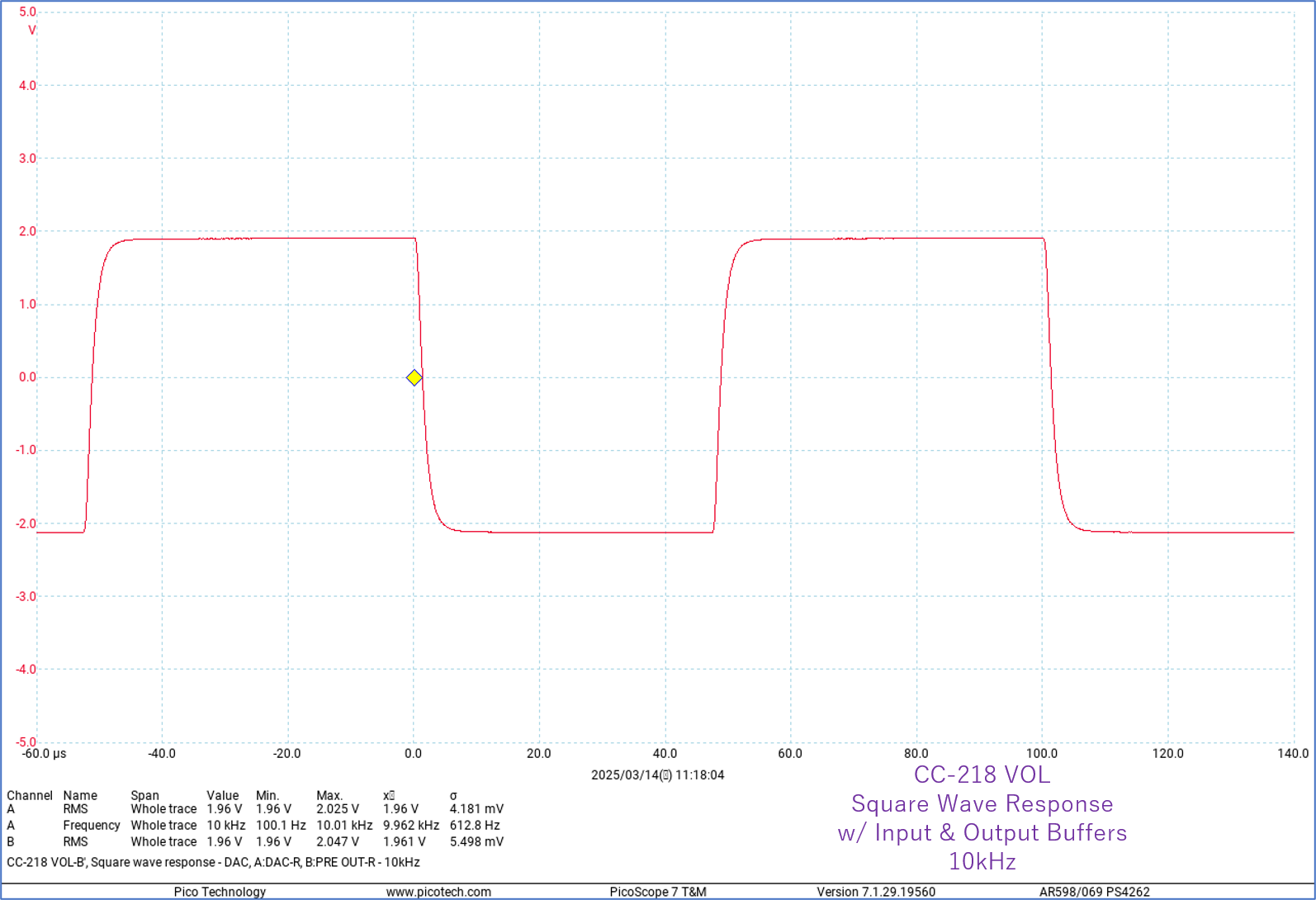

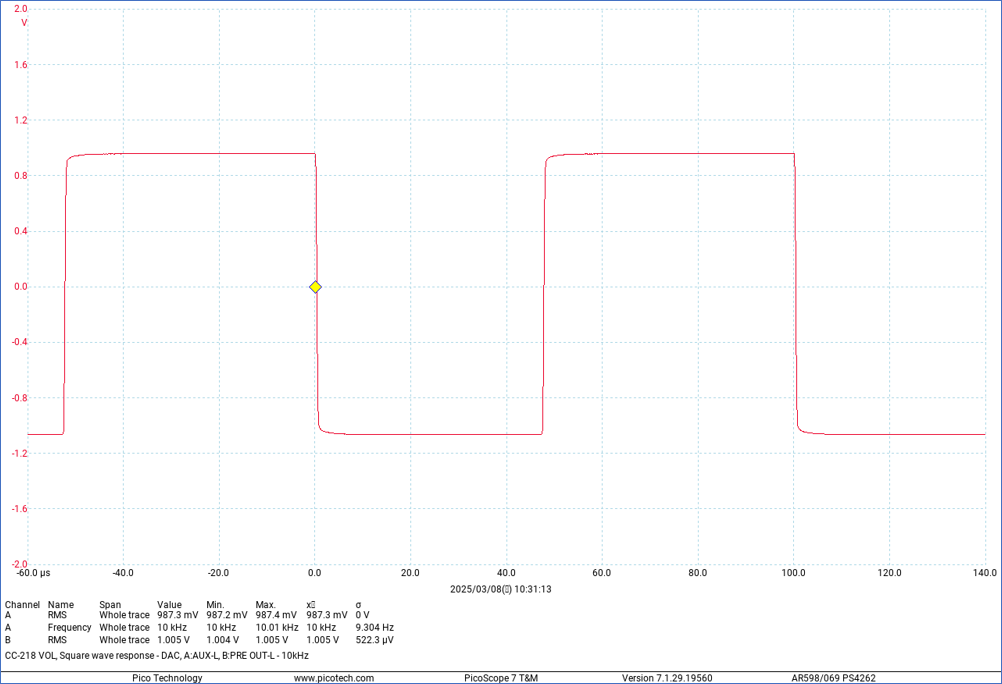

| Frequency range | DC ~ 160kHz (-3dB) (w/ input & output LPF). DC ~ 800kHz (-1dB) (w/o input & output LPF). |

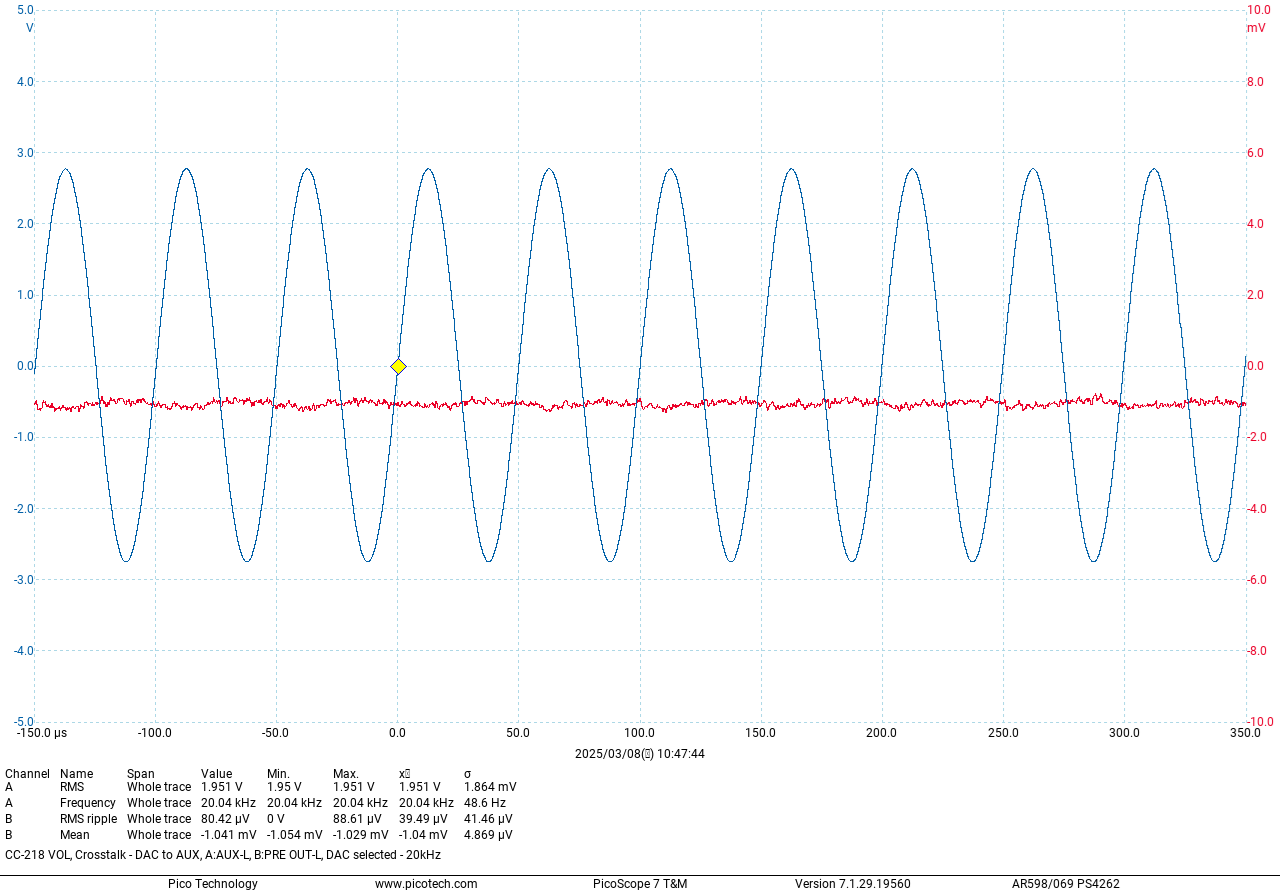

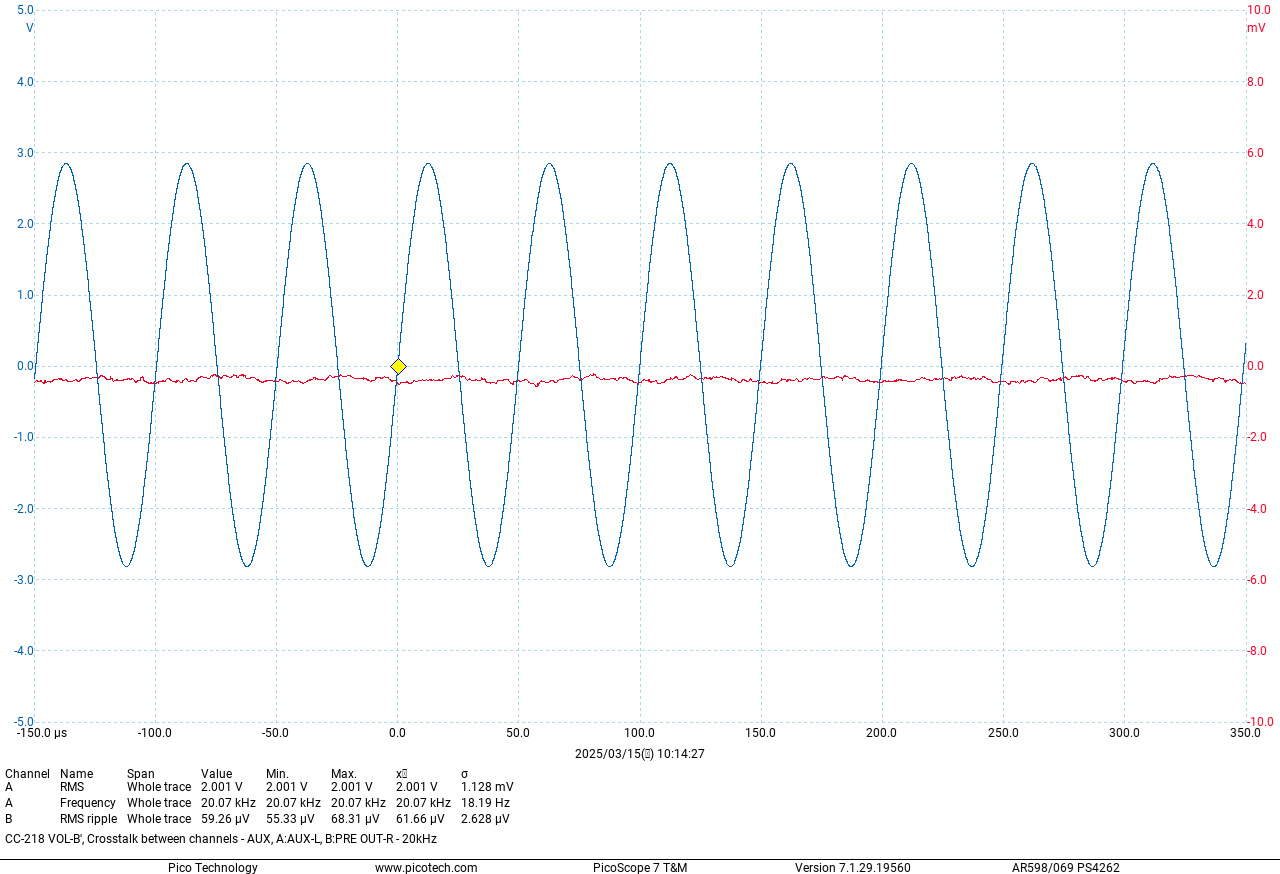

| Channel separation | 90dB or higher (@1kHz), 90dB or higher (@20kHz). |

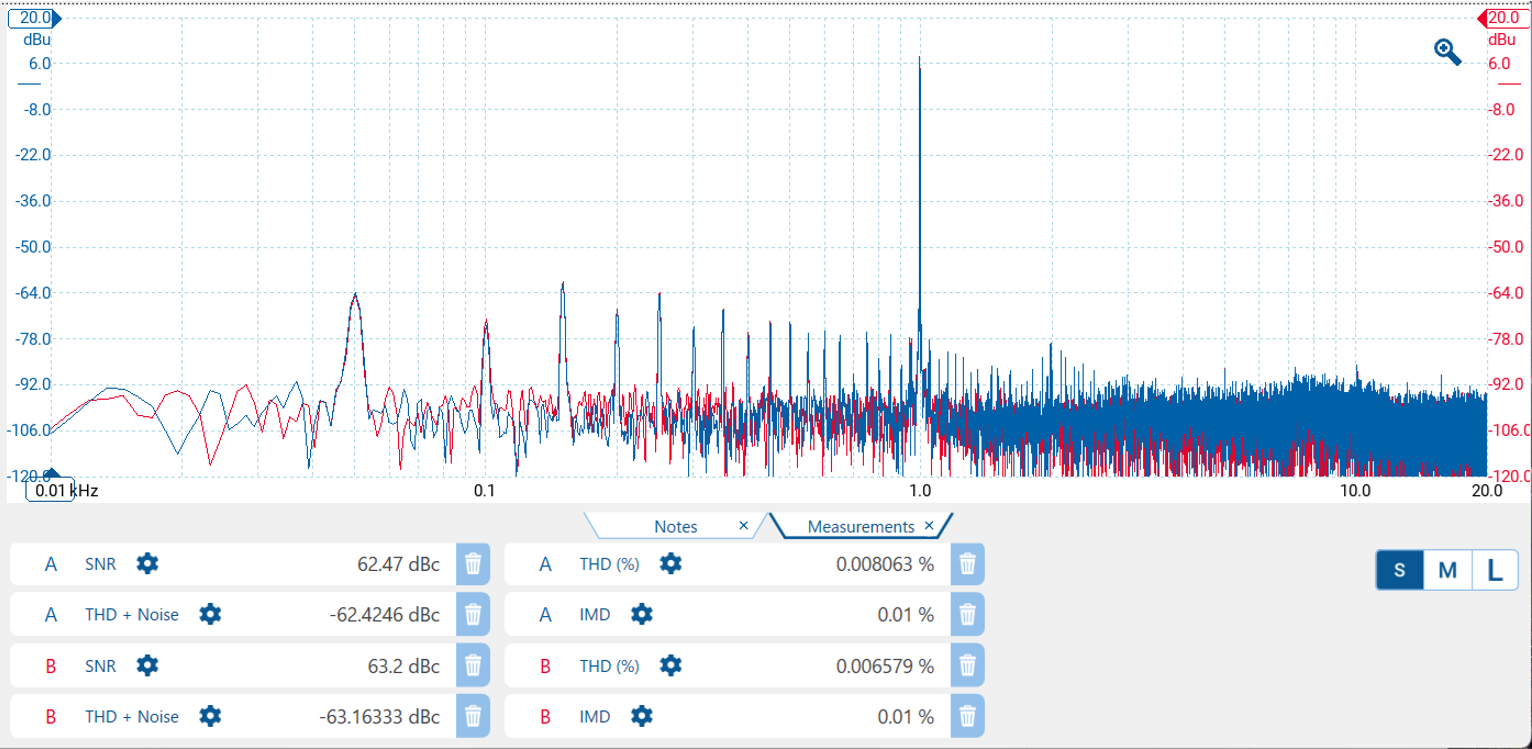

| Distortion | Smaller than the measurable limit of Tonochi Methods. Measured data: THD: 0.008%, IMD: 0.01%. (true values are smaller than these) |

| SNR | Higher than the measurable limit of Tonochi Methods. Measured data: 67dB. (true value is higher than this). Residual noise: 70uV or lower (w/ the filter of the instrument disabled) |

| Console feature | Using PC and a terminal app on it such as Tera Term. Connection: DVCS port of CC-218-->Mini plug/D-Sub cable-->RS232C/USB cable-->USB of PC. |

| DVCS | Asynchronous serial communication: 19,200 baud, 8bit, no parity bit, w/o

flow control. Electrical charisteristic: Compliant w/ RS232C (only TX, RX and GND are used). When a DVCS device (Xover or power amp that has DVCS port) is connected, the DVCS port is assigned for DVCS feature. When PC is connected, DVCS port is assigned for console feature (automatical detection). |

| Power supply | AC100V or AC200V. (adaptor or power cord for 200V is necessary to use 200V

outlet) Voltage range: 85 ~ 264V. |

| Power dissipation | 13W (when all LEDs of display are on). 12W (when all LEDs of display are off). |

| Dimensions | Dimension: 360(W) x 142(H) x 190(D) mm (not including protrusions). Weight: 4.5kg (not including power cord). |

Level diagram

The specified maximum output level is +3dBFS (=2.8V), though, it can be extended to +10dBFS(=6.3V) by remote control.

User interface

The CC-218 has a unique user interface.

To avoid causing stress for the user (myself) when playing analog discs,

a variable resistor (VR) for the volume knob instead of a rotary encoder.

The VR's rotational range is 300 degrees. This allows the user to reduce

the volume from maximum to minimum within only one second.

When lowering the stylus onto a disc or at the end of playback, the volume

must be turned down . This prevents sudden loud noise from the loudspeakers.

Such operation is far easier with VR. As for MV-217, which employs a rotary

encoder, it takes about 10 seconds to bring the volume from maximum to

minimum. By adopting VR, CC-218 achieves exactly the same operability as

a pure analog amplifier. In particular, when the display is set to 'Disable'

mode (always off), CC-218 is indistinguishable from a pure analog amplifier.

Because VR exhibits low linearity within approximately 10 degrees near

its start and end positions, the gain is fixed in those ranges. Within

10 degrees of the starting point, the gain is set to −∞ dB, and within

10 degrees of the endpoint, it is set to +3dB. Gain settings between more

than −∞ dB and less than −60 dB are considered unnecessary. Adjustment

is performed in 1dB steps.

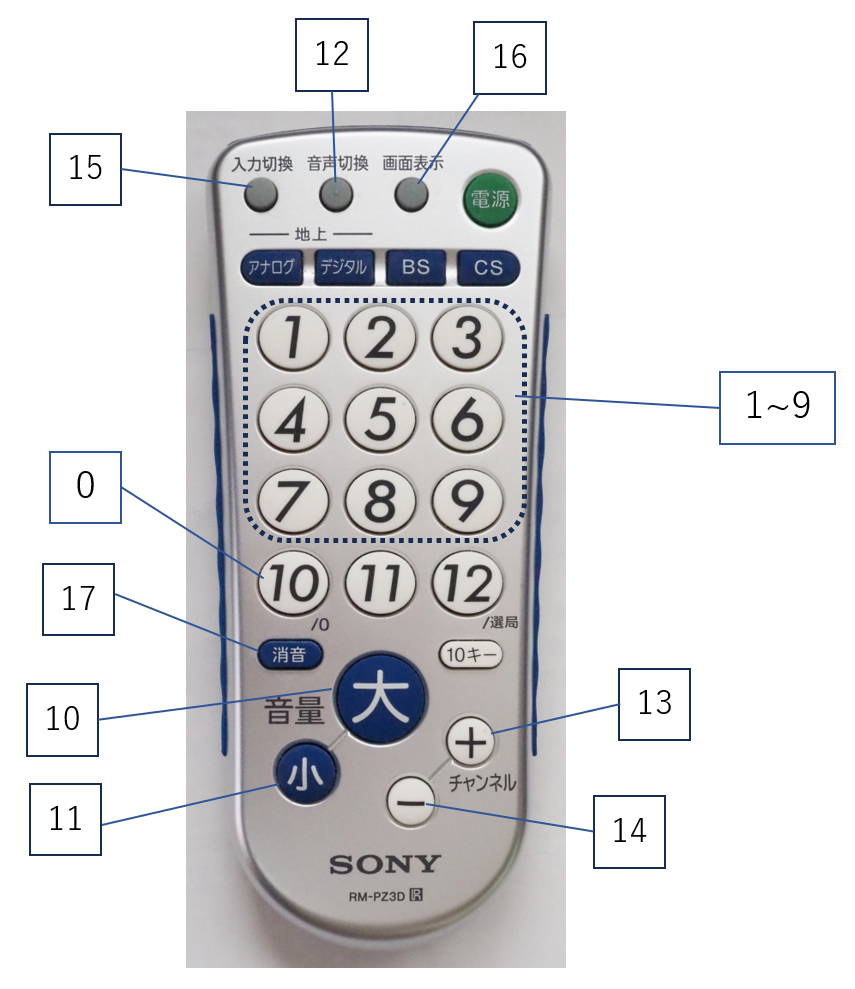

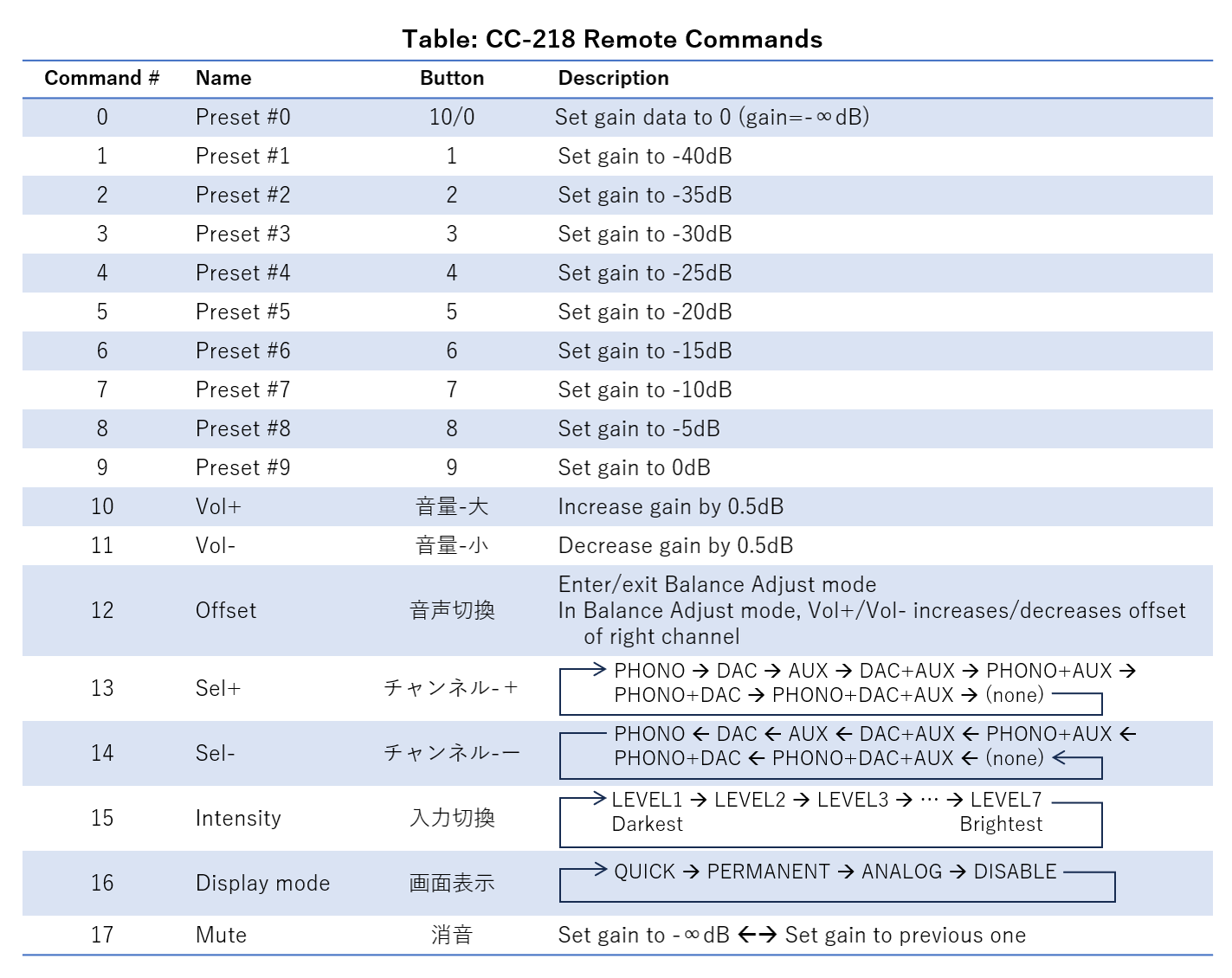

Spec of remote

With the IR remote, the user can adjust gain in 0.5dB steps.

For explanation of 'Display mode', see "Appearance Design".

I also put a lot of thought into the mute function. I really don’t like

it when the sound just cuts off suddenly, so I set it up to fade out over

about 0.9 seconds instead. When unmuting, it fades back in the same way.

This was one of my own “picky requirements,” too.

Design

I made the appearance my top priority in this project as in MV-217 project. I planned the design steps as follows (these steps aren't separate, and overlap each other):

Appearance design ==> Mechanical design ==> Layout design ==> Circuit design ==> Firmware design.

I selected the same parts and materialsas as MV-217 which concern the appearance.

Key Parts and Materials

I selected many parts and materials I hadn't used before, as I did in the

previous project (MV-217 X'tal).

- PCB

- I used my original PCB (Print Circuit Board) for the first time in my life.

I could hardly master PCB dsign in spite of my efforts for the past few years. However, I really need a PCB in order to realize a ultra-low noise phono equalizer (Phono EQ) for MC cartridge. I had to employ PCB. I decided to use PCBs for the phono EQ and the other boards. They are all doubl-sided PCBs. - AC/DC converter

I selected XP Power's EML15USxx again, which I had selected for MV-217 and was satisfied.

Two units of EML15US24-T (24V 0.6A) for the analog circuits, and one EML15US05-S (5V 3A) for the digital circuits.

<Manufacturer's website (https://www.xppower.com/)>

- TV remote

For the remote control, I chose to use a TV infrared remote. Many models are available on the market, so it's easy to pick one that suits my preferences.

The model I selected is the Sony RM-PZ3D. For a TV remote, it has relatively few buttons, which makes it look easy to use. Since its appearance is different from the remotes for the living room TV (Sharp) and the STB (Panasonic), there's no risk of confusing them in a hurry.

The issue was how to receive the signal from this remote. According to the datasheet of an infrared receiver module, Japanese-made remotes use a Pulse Position Modulation (PPM) method with a 38 kHz carrier frequency. I decided to use the Vishay TSOP34838, which has the functionality to receive and demodulate such signals.- ICs for audio

- Electronic volume: Texas Instruments (Barr Brown) PGA3210

Ultra-low noise op amp: Linear Technology LT1115

Other op amps for audio: Texas Instruments (Barr Brown) OPA627, Texas Instruments (National Semiconductor) LME49860, LME49720 - MCU

- I chose Microchip PIC18F2520.

Its CPU is 8-bit. For controlling an amplifier, an 8-bit CPU has enough performance. I chose the PIC microcontroller because it is widely used around the world and its supply is considered stable. I also plan to use it in amplifiers I build in the future. It's an easy-to-use MCU (Microcontroller Unit) with a built-in reset circuit and clock oscillator.

CPU: 8-bit CISC(Complex Instruction Set Computer)

Clock frequency: up to 8MHz (internal clock), up to 40MHz (external clock)

Memory: program memory (flash memory) 32KB, data memory (RAM) 1.6KB, EEPROM 256B

Peripherals: Timer x4 (including capture, comparator, PWM features), Serial port x2 (USART, MCCP(I2C Bus)), 10-bit ADC, WDT, etc

New Technologies

Here are some technologies I experienced for the first time. They are already commonplace, but new to me.

- Microcontroller-based control

- In an analog preamplifier, the component most prone to causing sound quality

degradation is the volume control. Variable resistors (VR or potentiometer)

already have less-than-ideal contact quality, and they also tend to deteriorate

over time. Dual-gang VRs for stereo use also suffer from a drawback called

"gang error," caused by inconsistencies between the two potentiometer

elements.

The most practical solution is to use an electronic volume control. There are ICs specifically designed for this purpose, allowing for a single-chip implementation. However, electronic volume controls require microcontroller-based control. It was precisely the desire to use an electronic volume control that led me to adopt microcontroller control.

With microcontroller control, incorporating an infrared remote control also becomes possible.

- PCB design

- I decided to use PCBs in this project. So I had to design the PCBs for myself. As I mentioned above, it is hard for me to master PCB design techniques, though, DesignSpark PCB, a PCB CAD with excellent user interface, made it possible to design PCBs meeting my requirements.

- Infrared remote

- I had long been frustrated by the lack of a remote control on my preamps.

MV-217 was the first model I tried to equip with one, but for some reason,

it didn’t work. Since the MV-217 used a commercially available module,

I couldn’t debug it and eventually gave up. This time, both the hardware

and firmware are homemade, so I’ll make sure the remote control works.

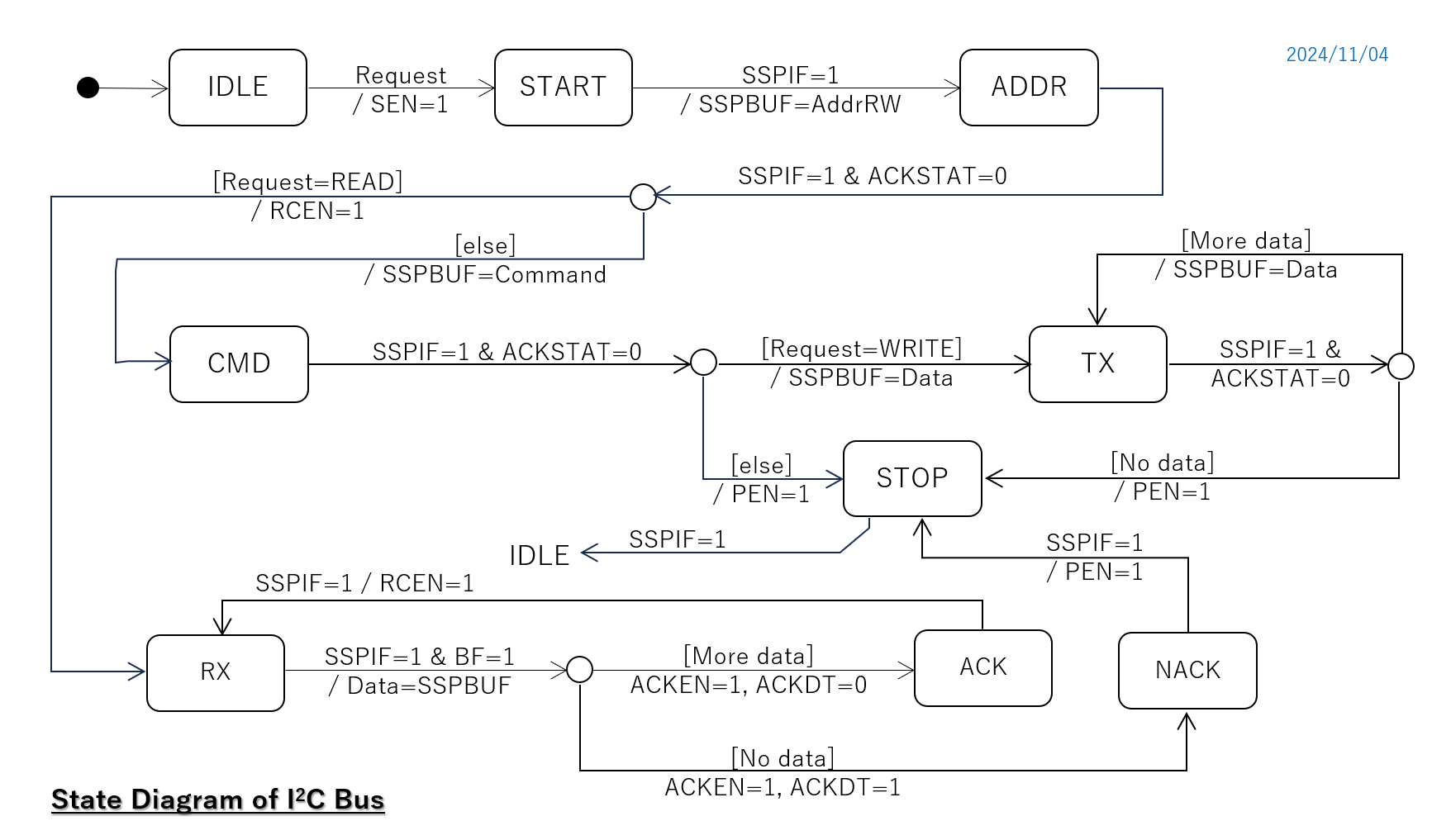

A remote control indirectly affects sound quality. Volume and sound quality are closely related, and to achieve the best possible sound, fine volume adjustments are essential. But if you can’t adjust the volume from your listening position, you have to go back and forth between the amp and your seat. That kind of hassle makes it harder to fully enjoy the music—and as a result, it may even make the sound feel less satisfying. - I2C Bus

- It’s a widely adopted standard for internal device communication. Since it’s an interface for connecting ICs to other ICs, it was named I²C. It’s used in many types of LSI chips. Once you learn this technology, you’ll be able to make full use of advanced LSIs.

Appearance Design

The design combines elements from two of my past works: PA-210 Simplicity and MV-217 X'tal. It reflects my personal taste while also offering a familiar and intuitive user experience.

| PA-210 Simplicity | MV-217 X'tal |

|

|

Design of Front Panel

The components used on the front panel are the same as those on the MV-217.

It’s essentially MV-217’s layout turned sideways, with two units placed

side by side.

By removing the clear plastic screws, you can detach the front panel.

These clear screws also function as power indicators.

As with the MV-217, the knobs are made of wood. To achieve a lighter tone,

I chose cherry wood.

Three 7-segment LEDs are used for the numeric display. I initially intended

to use orange LEDs.

For the selector indicators, a red LED is used for PHONO, and orange LEDs

are used for DAC and AUX. This follows the design of the indicators on

the PA-210.

A key point is to make the LEDs invisible when they are turned off.

To check the appearance, I conducted a preliminary experiment. I applied

stickers to ROHM’s orange 7-segment LED and turned them on.

To my surprise, I found that light leaked into adjacent segments. In the

photo below, the brightness difference between a lit segment and its adjacent

unlit segment looks clear, but to the naked eye, the difference is barely

noticeable. For example, when displaying '0', it looks more like an '8'.

This is unacceptable. I never expected ROHM to ship such low-quality products.

Since I couldn’t find any orange 7-segment LEDs available for purchase

in single units, I reluctantly selected a plain red LED. I’m not fond of

red LEDs because they are too harsh on the eyes, though.

| Experiment using ROHM LA-601, 7-seg LED Light leaks into adjacent segments. To the naked eye, the lit segments look a little darker. |

The numeric display can show values from -99 through +99, but in actual

use, it displays gain values from -95.5 through +10.

A gain of -∞ dB is represented by just a single '-'. A 0.5 dB increment

is indicated by a decimal point only.

|

|

|

|

| -∞dB (mute) No numeric character is displayed |

-60dB |

-9.5dB The upper digit's '0' is suppressed The decimal point indicates '0.5dB' |

+3dB '+' is not displayed (can't be) |

| Mismatch Sign |

|

| It indicates that the angle of VOL knob doesn't match the actual gain |

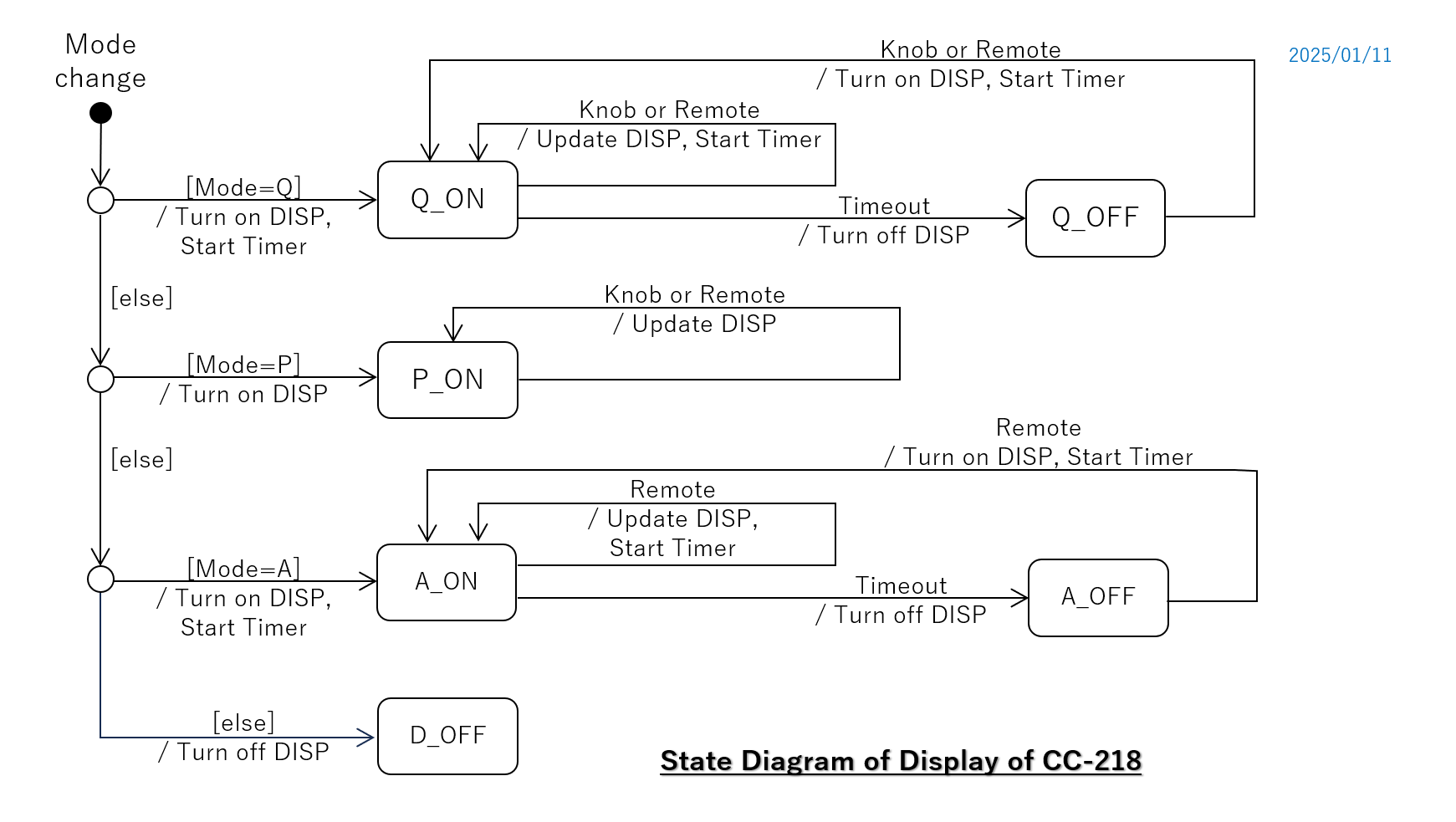

The Front Panel Display operates in one of the four modes:

- Quick

- Display turns on only when the user changes the gain or the source.

Display turns off after three seconds elapse, if the user turned the knob.

Display indicates 'Mismatch Sign' after three seconds elapse, if the user used the remote.

This is the default mode. - Permanent

- Display is always on.

- Analog

- Display does not turn on when the user turns the knob, while Display turns

on for three seconds when the user uses the remote.

CC-218 looks like a pure analog amplifier unless the user uses the remote. This is why I named it 'Analog' mode.

If the user uses the remote, Display indicates 'Mismtach Sign' three seconds later.

- Disable

- Display is always off.

Construction

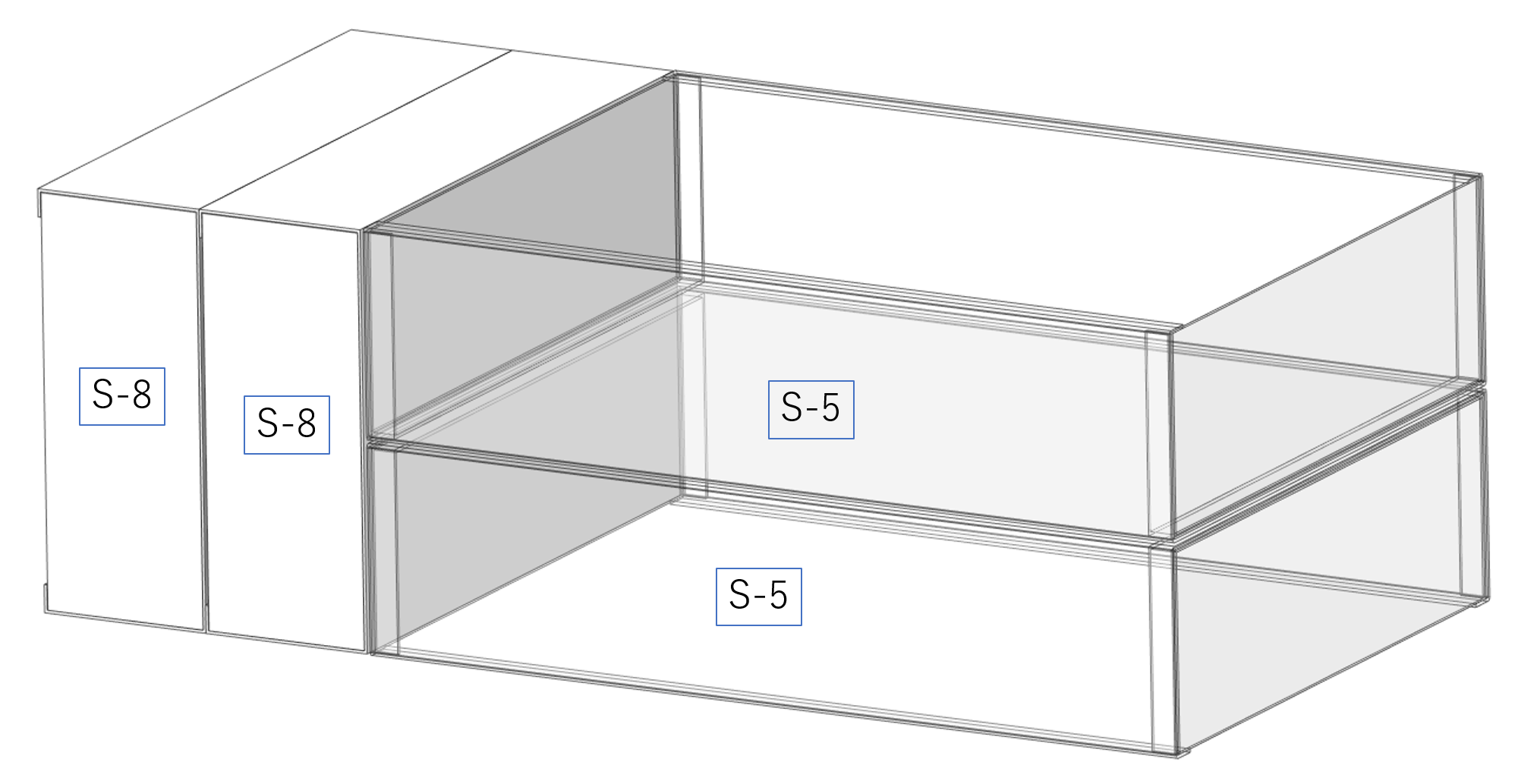

At this stage, I decided to use commercially available chassis to construct the case: two units of LEAD S-5 and two units of LEAD S-8. The S-5 will be used for the clean compartment, and the S-8 for the dirty compartment.

Clean compartment – houses the analog circuitry

Dirty compartment – houses the digital circuitry and power supply unit

At this stage, the plan was to install L-ch (the left channel) circuitry in the upper S-5 unit and R-ch (the right channel) in the lower one—this is the so-called dual-mono construction, the same structure used in the PA-202, PA-203, and PA-210.

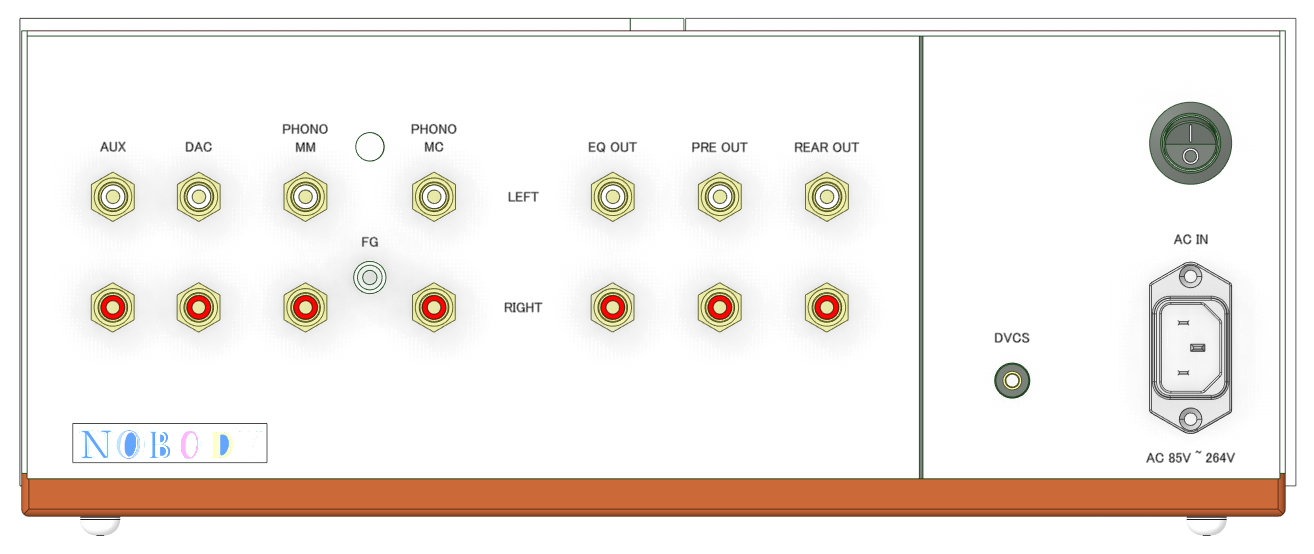

Design of Back Panel

On the back side, an aluminum panel with a sticker on it will be mounted.

The PHONO input supported both MM and MC cartridges at this stage, though,

it was later revised to support MC only.

Design of the other out panels

Top Panel and Side Panels will be painted using automotive spray paint. The color will be silver metallic.

A 12mm-thick MDF board will be attached to Bottom Panel. This is intended to lower the center of gravity of the case and give it a more stable appearance, while also providing the added benefit of suppressing vibrations. The MDF board will be painted brown.

Mechanical Design

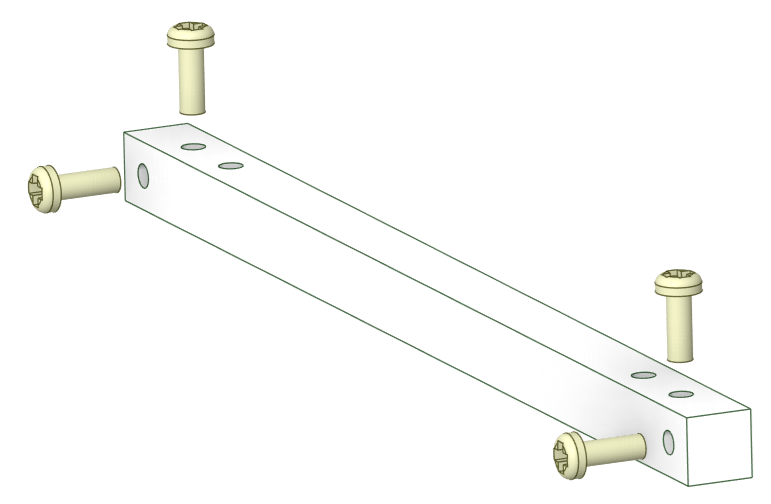

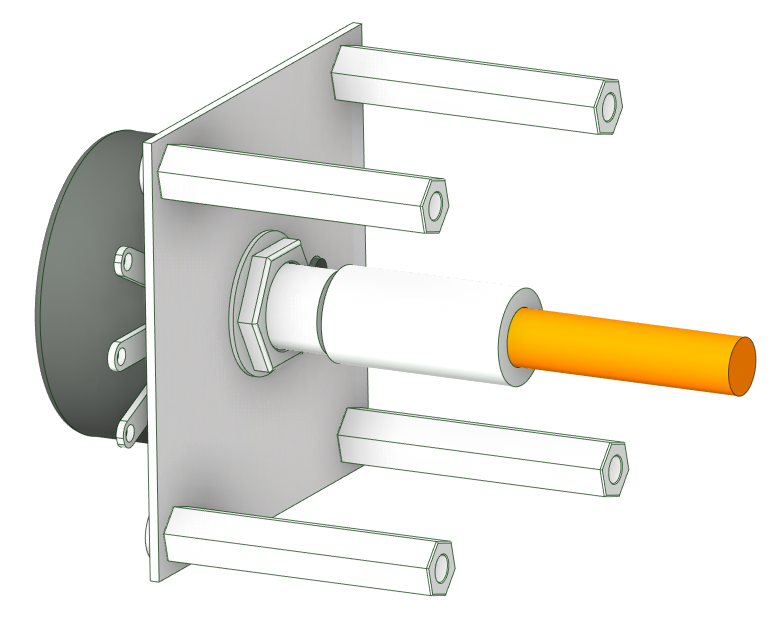

The “bar nut” that I devised during the design of the PA-210 has been adopted once again. It’s a mechanical part made by drilling a threaded hole into an aluminum square bar, allowing it to function as a nut. The term “bar nut” is a word I coined myself. It is used to fasten the chassis and panels together.

|

|

| Bar nut | Fastening chassis and panels together |

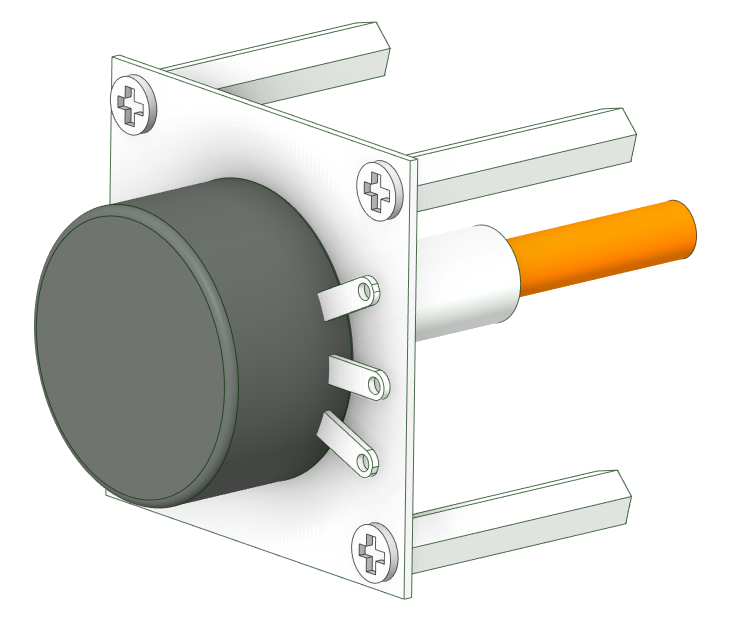

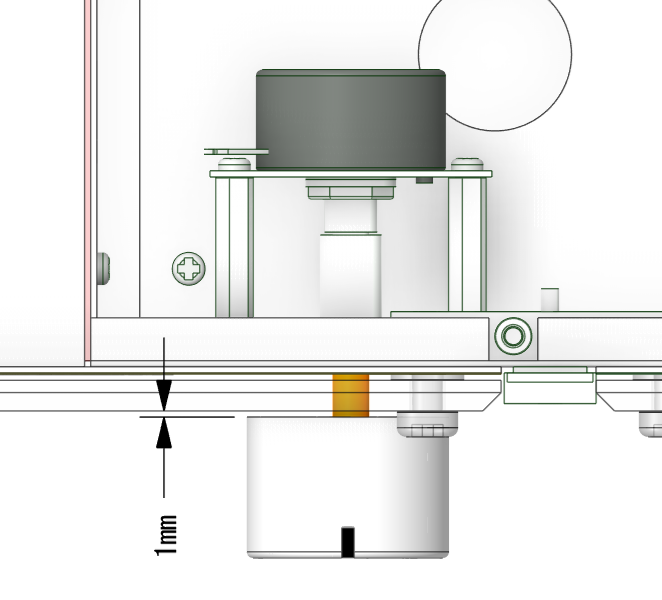

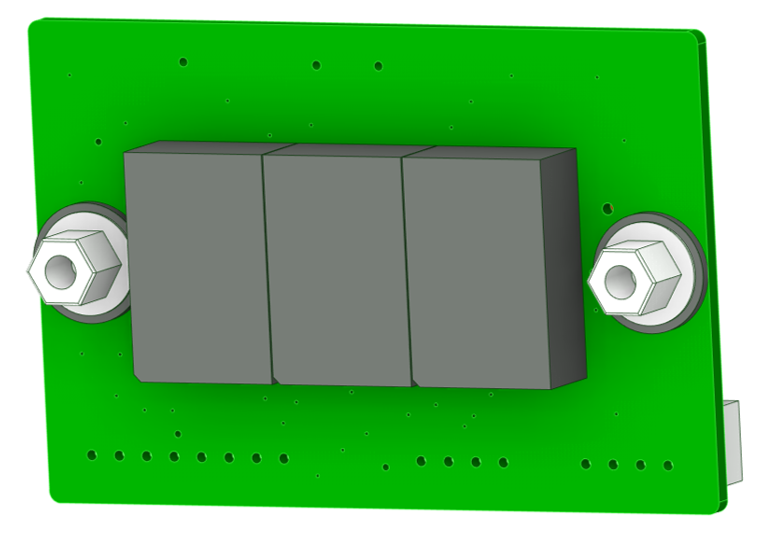

The VR and the rotary switch for input selection are mounted using a subpanel, just like in the MV-217. The VR is positioned slightly behind the front panel, and an extension shaft is attached to it. By adjusting the length of the extension shaft, the position of the knob is precisely aligned. The gap between the knob and the transparent panel is adjusted to be approximately 1 mm.

|

|

| VR Module (front) | VR Module (back) |

|

| Mounting VR Module - Top view |

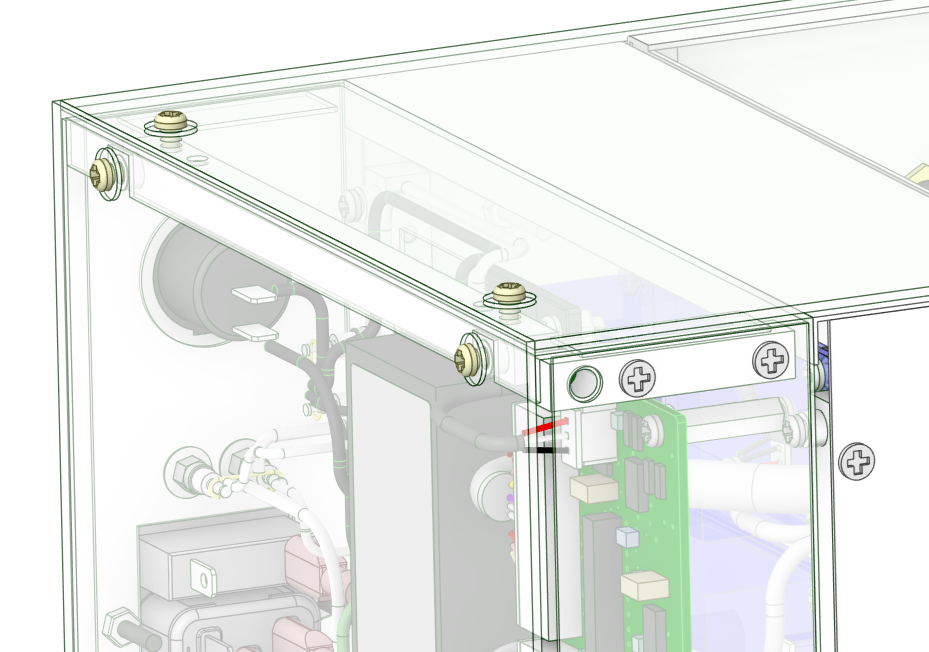

A 1mm-thick copper plate was placed between the upper and lower clean compartments.

Another 1mm-thick copper plate was also inserted between the clean compartment

and the dirty compartment.

This was done to achieve both electromagnetic shielding and vibration damping

effects.

As a result of the mechanical design, the appearance turned out as shown

in the illustration below.

Please note that this is not the final design. Since the mechanical design was done in the early stage of the development

process, some changes were made in later stages. The reason for presenting

this interim design is to share some of the design know-how with readers.

|

| Appearance after mechanical design - Front |

For more details on the mechanical design, please refer to the mechanical

design document below. Since this is not the final stage of the design,

dimensions are not included.

This document also does not cover the design of the panels, as changes

may occur during Layout and Wiring Design phase.

<Mechanical design document:CC-218_Design_Mech.pdf>

Layout and Wiring Design

In this design phase, there are the following three steps:

- Module layout

- Materialize the rough image of module configuration made during the stages of appearance design and mechanical design into concrete forms such as block diagram, and determine the arrangement of the circuit boards and the AC/DC converters inside the case.

- Definition of PCB specification

- Determine dimensions of PCBs, select connectors, and determine the positions of the connectors in the PCBs.

- Wiring design

- Design wire harnesses used for internal connections.

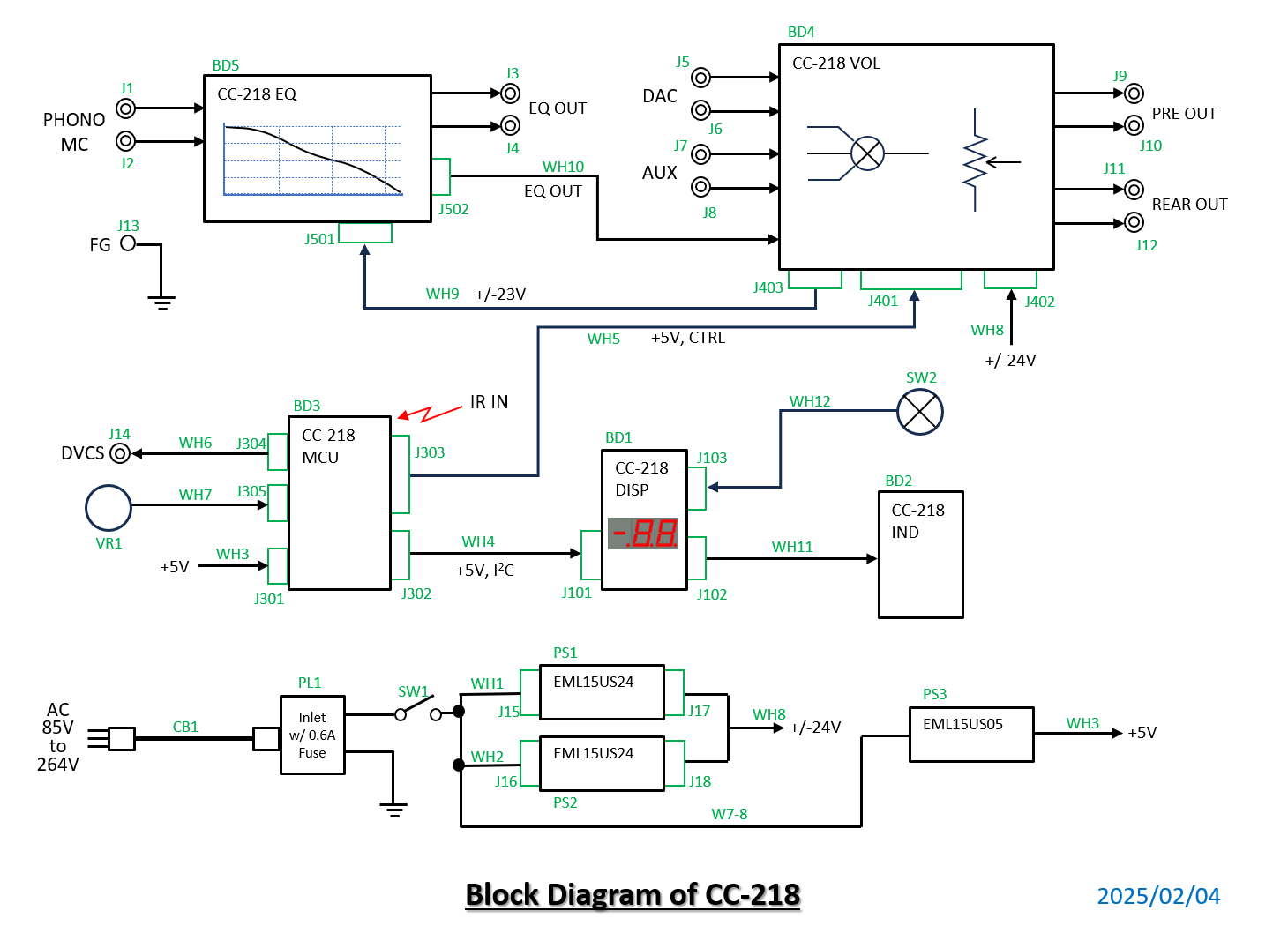

Module layout

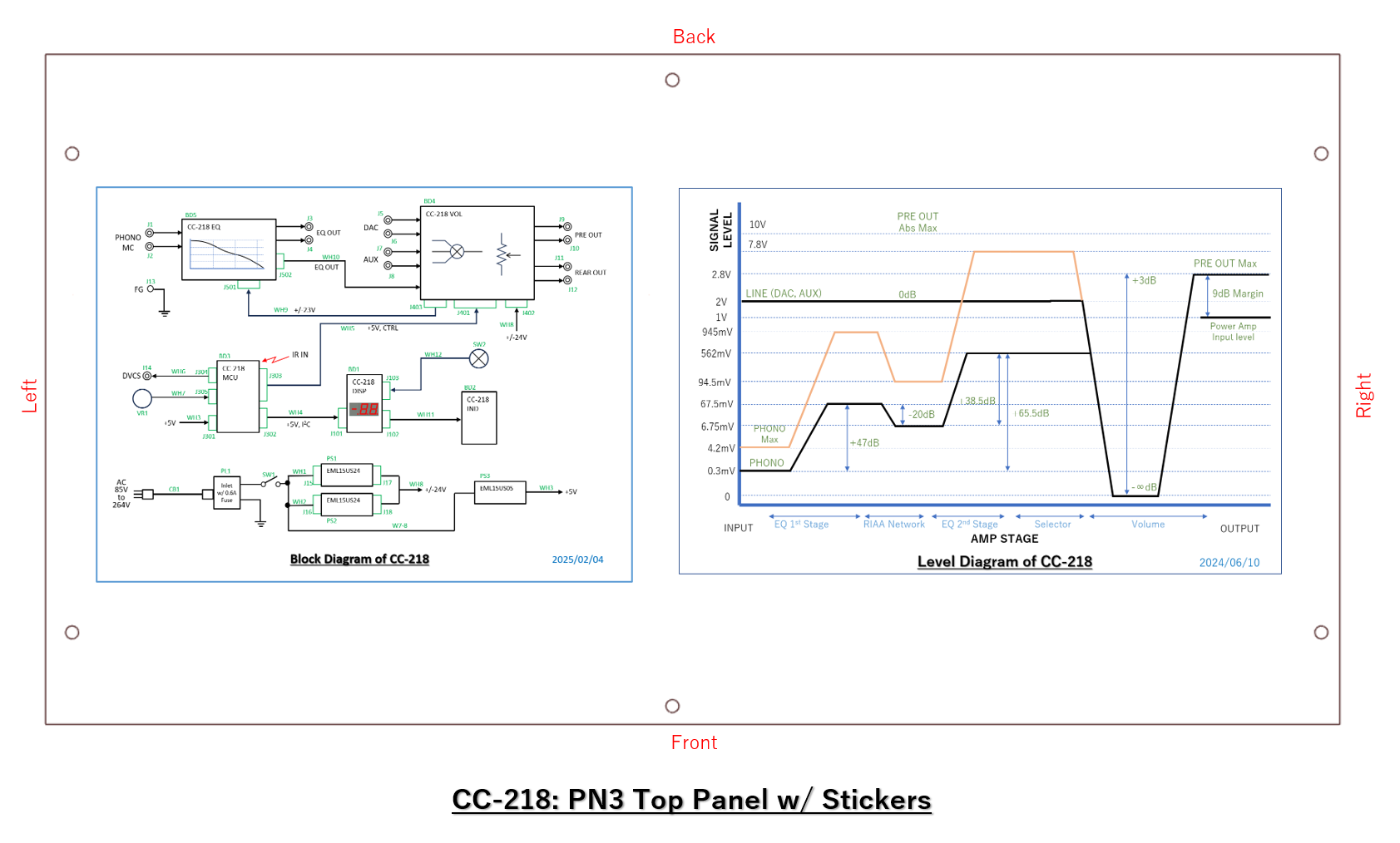

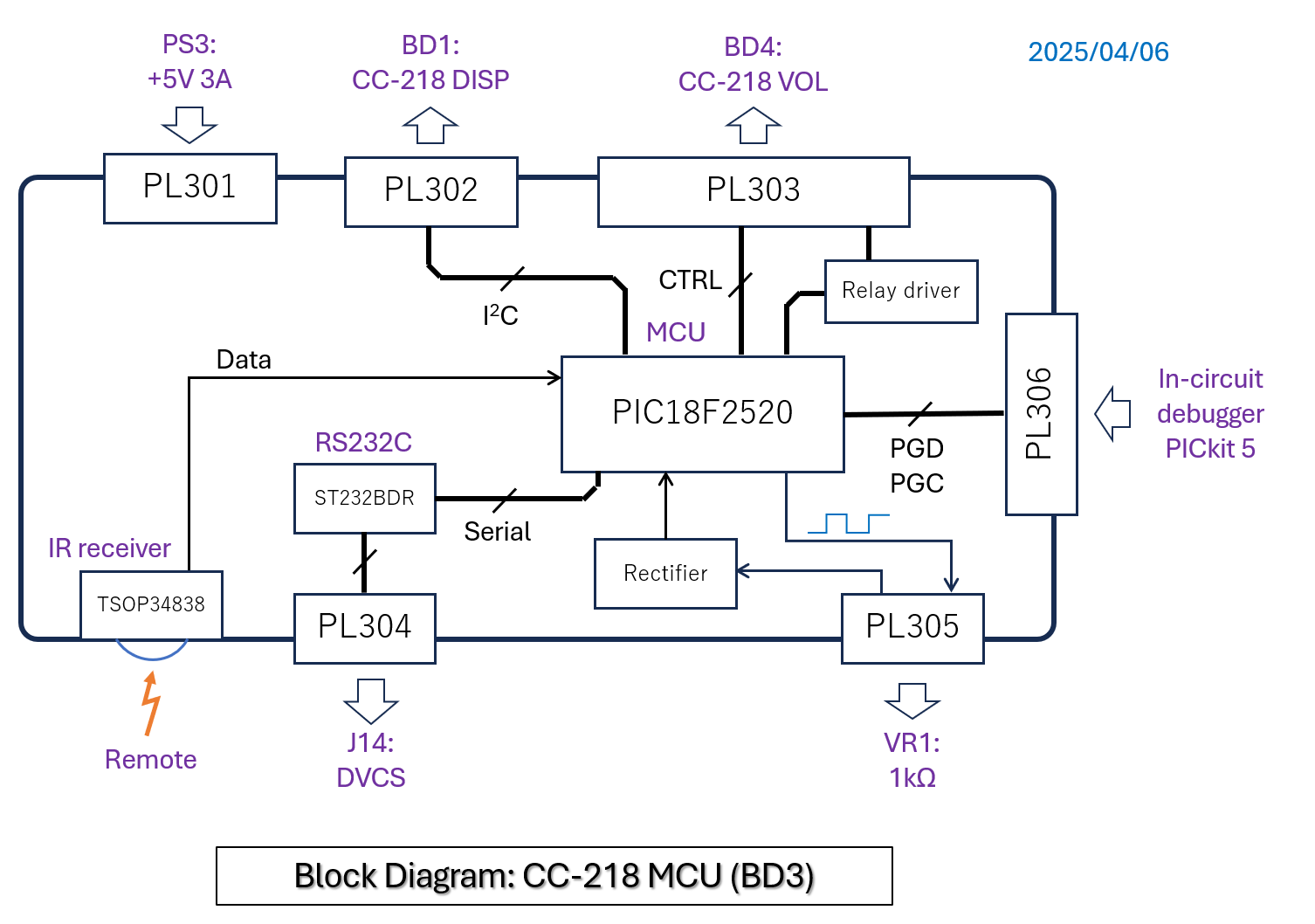

The figure below shows the block diagram of CC-218.

The table below describes each module and shows the arrangement.

| Reference designator | Module | Feature | Location |

|---|---|---|---|

| PL1 | AC inlet | AC inlet (IEC 60320 C14) w/ fuse holder | Back Panel |

| PS1 | AC/DC converter (UML15US24-T) |

Power supply unit for analog circuits +24V 0.6A |

CH3 PSU (Dirty compartment for PSU) |

| PS2 | AC/DC converter (UML15US24-T) |

Power supply unit for analog circuits -24V 0.6A |

CH3 PSU (Dirty compartment for PSU) |

| PS3 | AC/DC converter (UML15US05-S) |

Power supply unit for digital circuits 5V 3A |

CH4 MCU (Dirty compartment for MCU) |

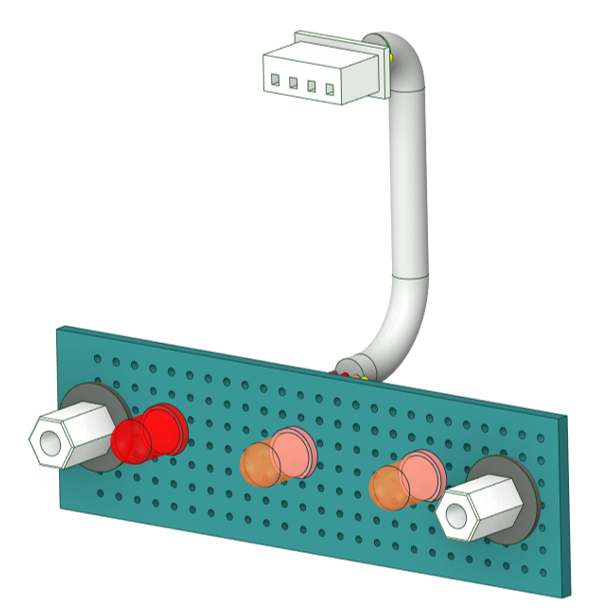

| BD1 | CC-218 DISP | 2.5-digit 7-seg LED Display Controlled by AS1115 |

CH1 AMP_VOL (Clean compartment) |

| BD2 | CC-218 IND | Selector Indicator Using 3 LEDs |

CH2 AMP_EQ (Clean compartment) |

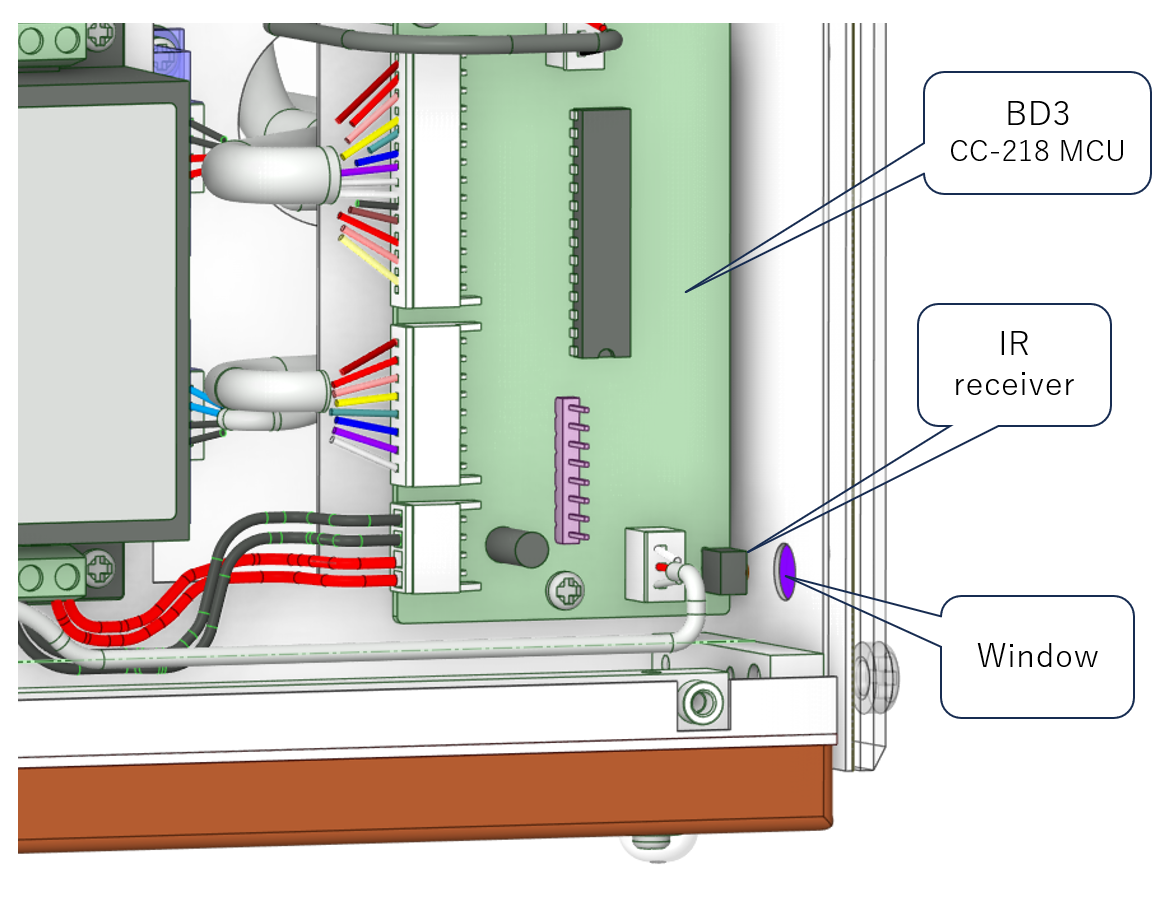

| BD3 | CC-218 MCU | Controller Board MCU: PIC18F2520 |

CH4 MCU (Dirty compartment for MCU) |

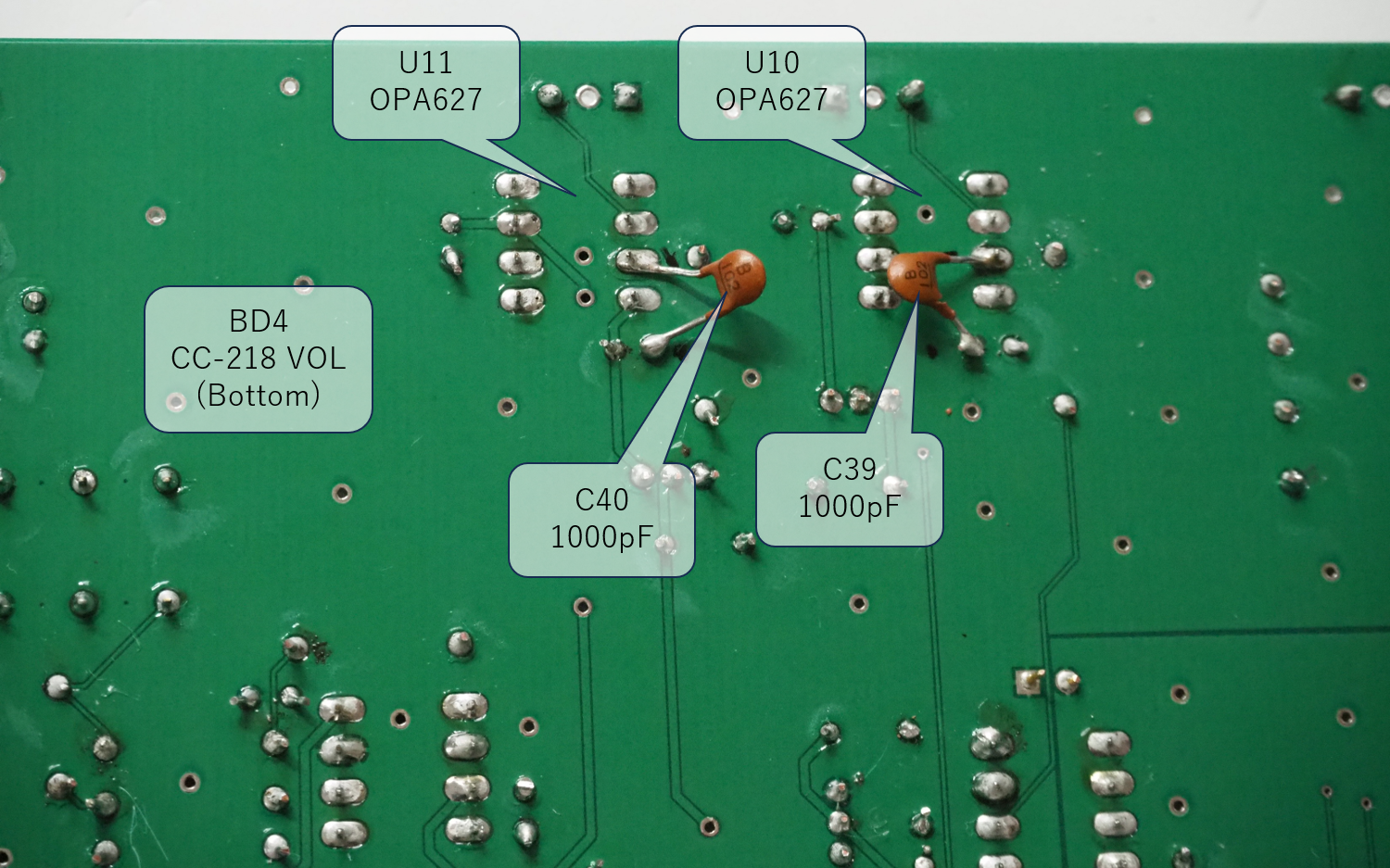

| BD4 | CC-218 VOL | Volume Board Using PGA2310 |

CH1 AMP_VOL (Clean compartment) |

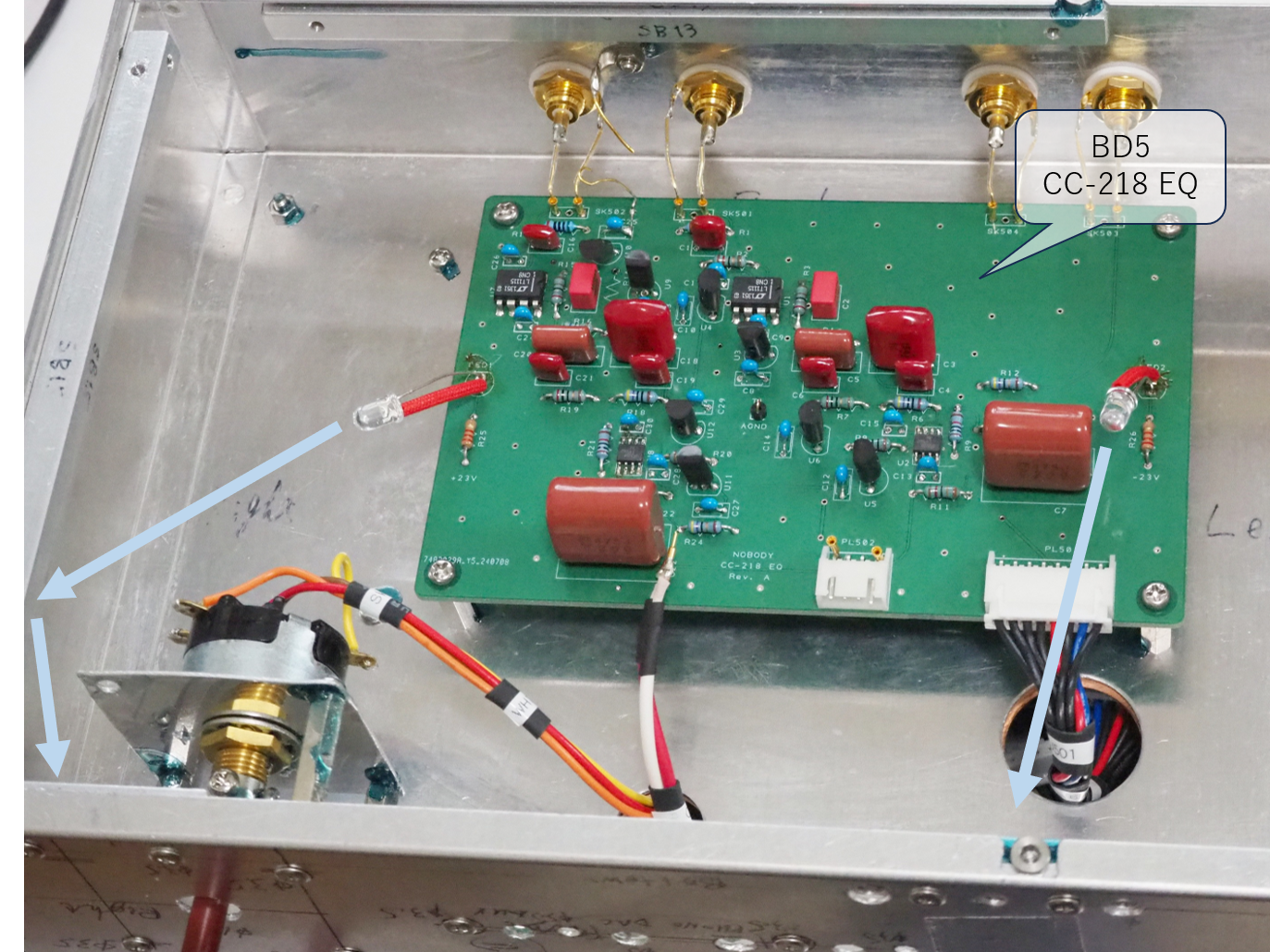

| BD5 | CC-218 EQ | Phono EQ Board Using LT1115 |

CH2 AMP_EQ (Clean compartment) |

Considering the layout, I realized that a dual-mono construction not only

fails to improve sound quality, but can actually degrade it. This is because

separating the ground (GND) for the left and right channels can create

ground loops and lead to unnecessary internal wiring. While the term “dual-mono

construction” sounds impressive, it is a structure with little real benefit.

I almost adopted it out of habit, since it was used in the PA-202, PA-203,

and PA-210, but ultimately decided against it.

In addition, sufficient channel separation can be achieved even with an

ordinary constuction.

I revised the mechanical design to place the volume board (BD4) in the

upper clean compartment and the phono EQ board (BD5) in the lower compartment.

Accordingly, the exterior appearance was changed.

Other modifications include making the PHONO input exclusive to MC cartridges

and replacing the AC inlet with one that has a built-in fuse holder, among

a few other changes.

|

|

| Front | Back |

Specifications of boards

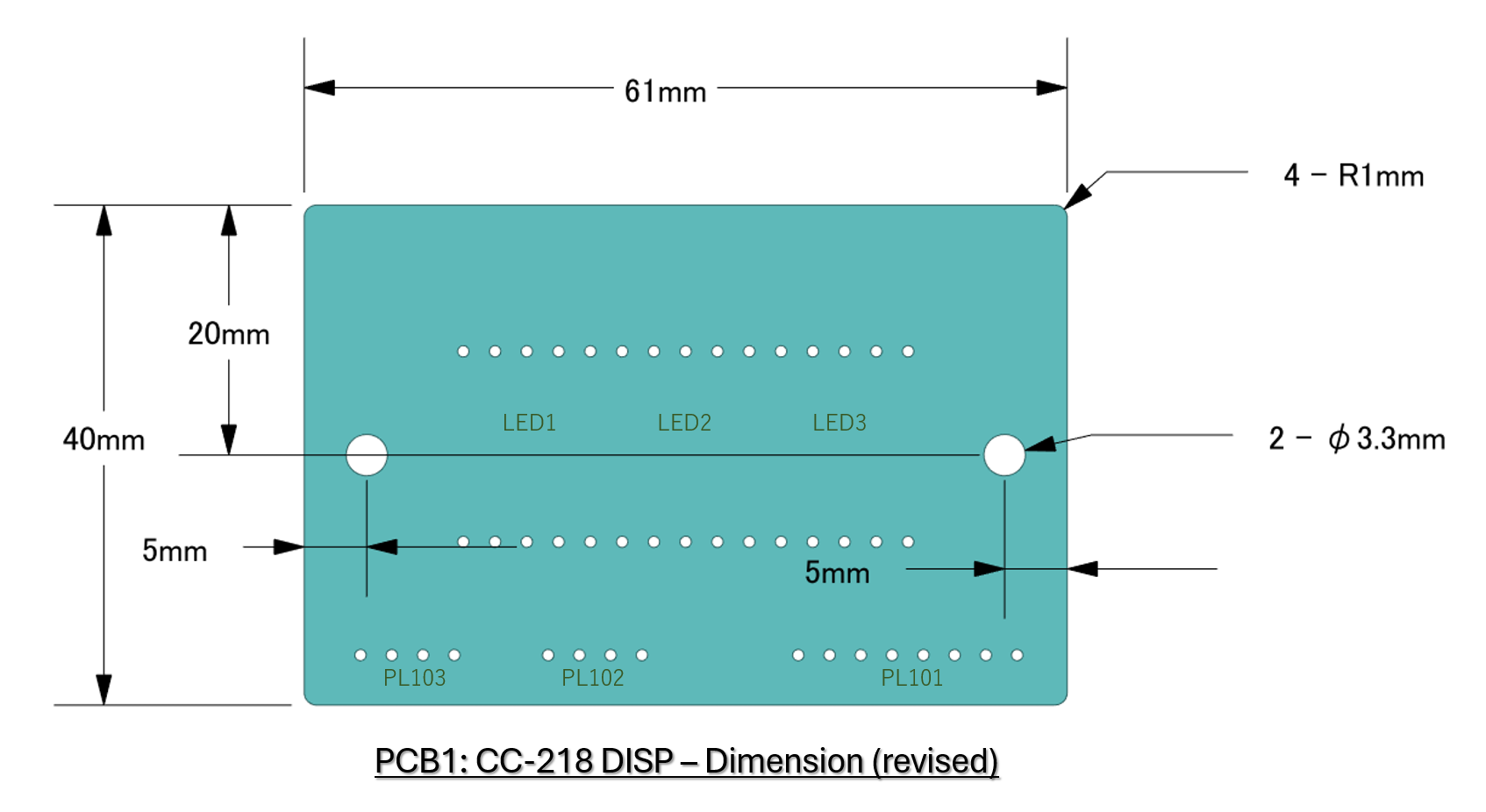

PCBs are used for BD1 and BD3 through BD5.

Each PCB is assigned the same number as its corresponding board's reference

designator. There is no PCB2; that number is unused.

| Reference designator | Module | Bare board | Specification |

|---|---|---|---|

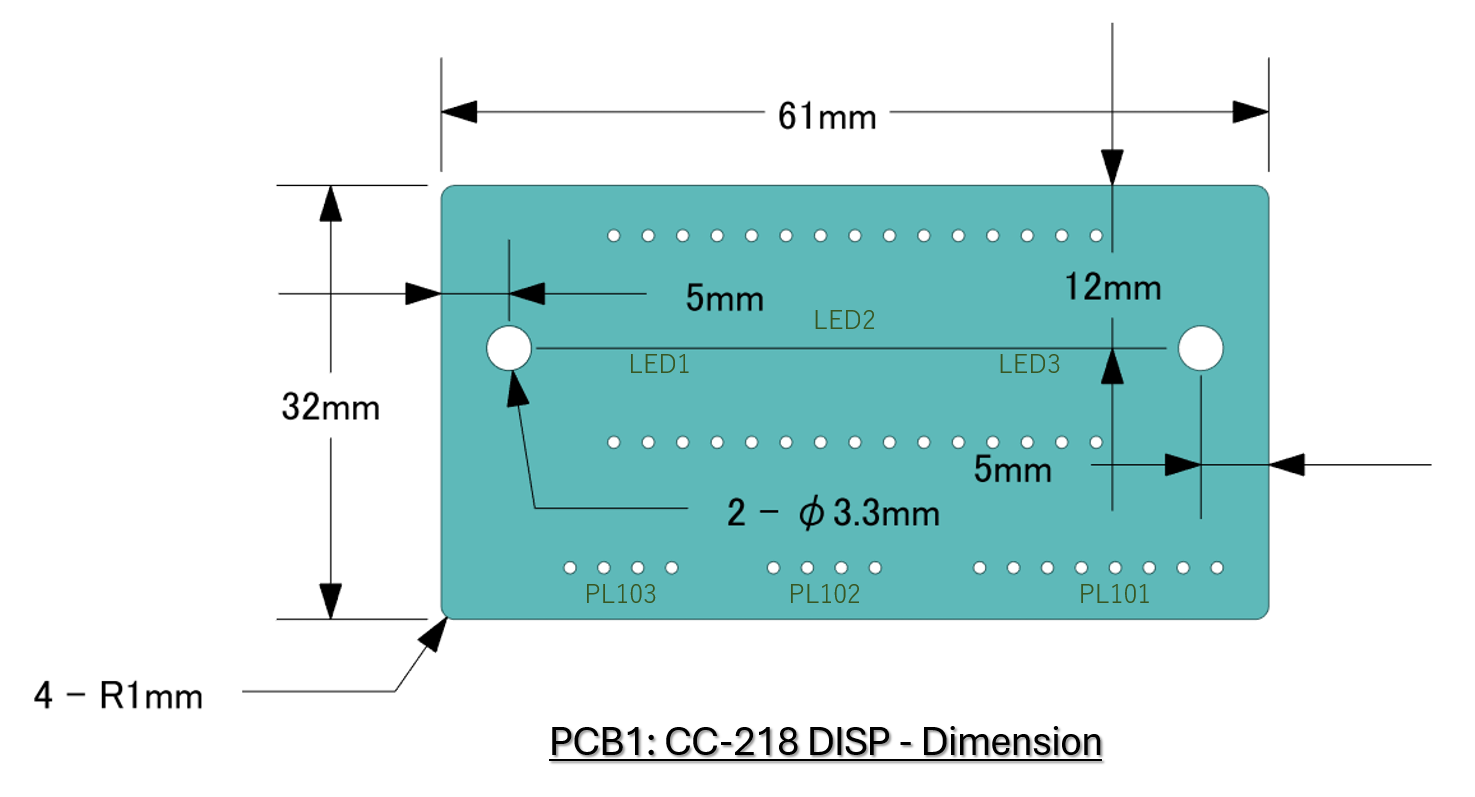

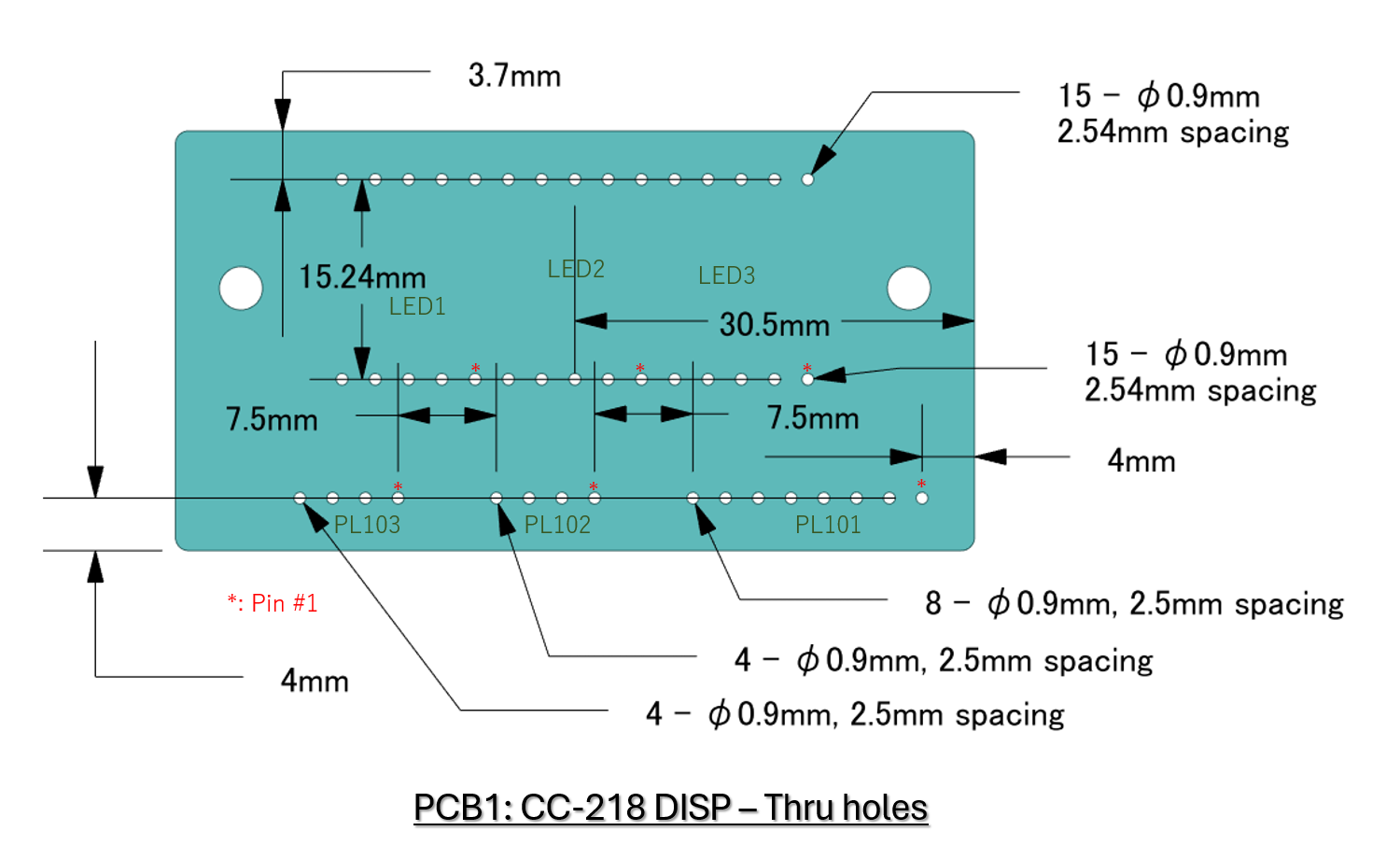

| BD1 | CC-218 DISP | PCB1 Manufactured by maker |

Double-sided thru hole PCB 1.6 x 61 x 32mm |

| BD2 | CC-218 IND | Selector Indicator Using 3 LEDs |

Single-sided universal board 1.6 x 68 x 20mm |

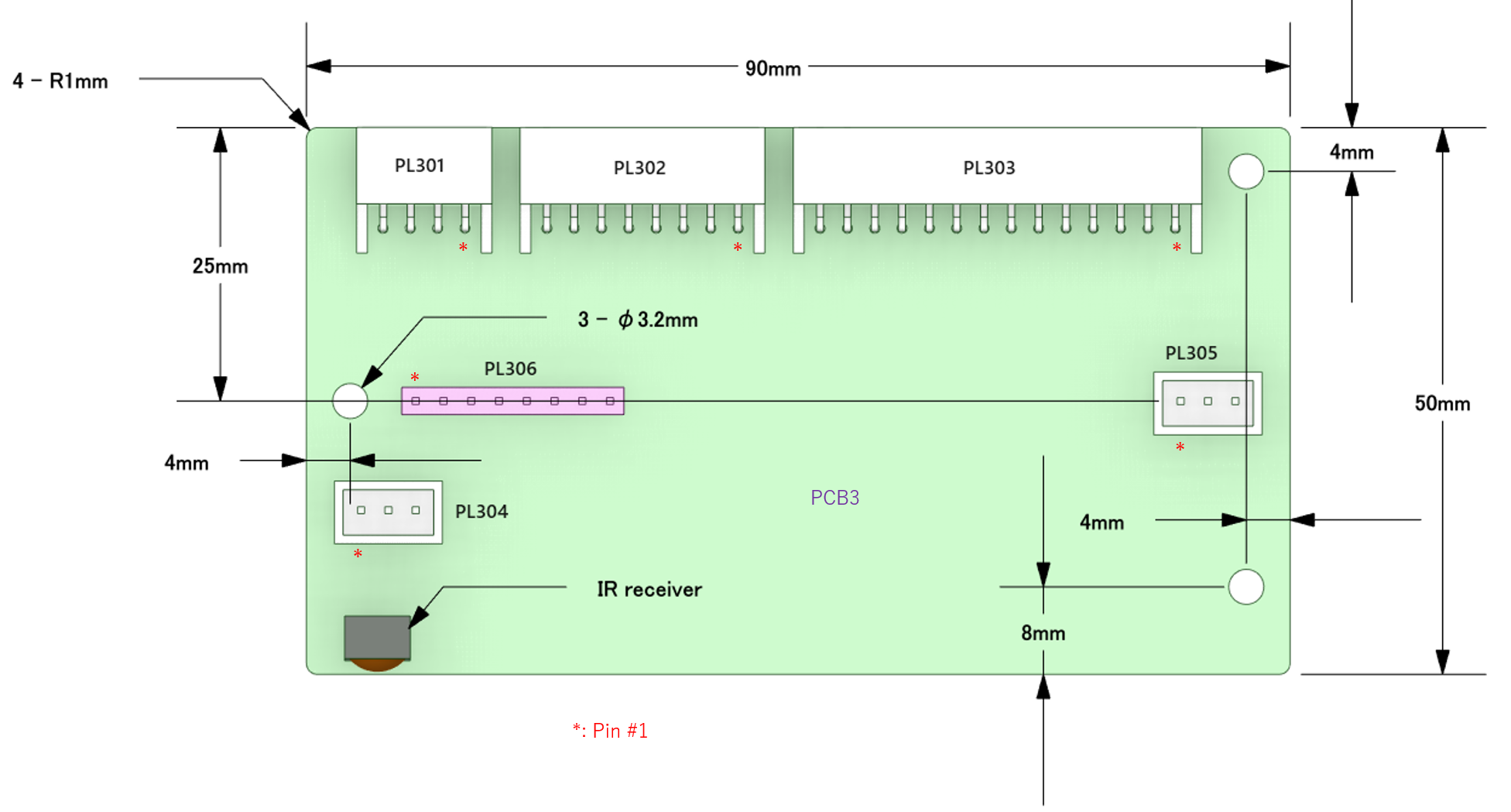

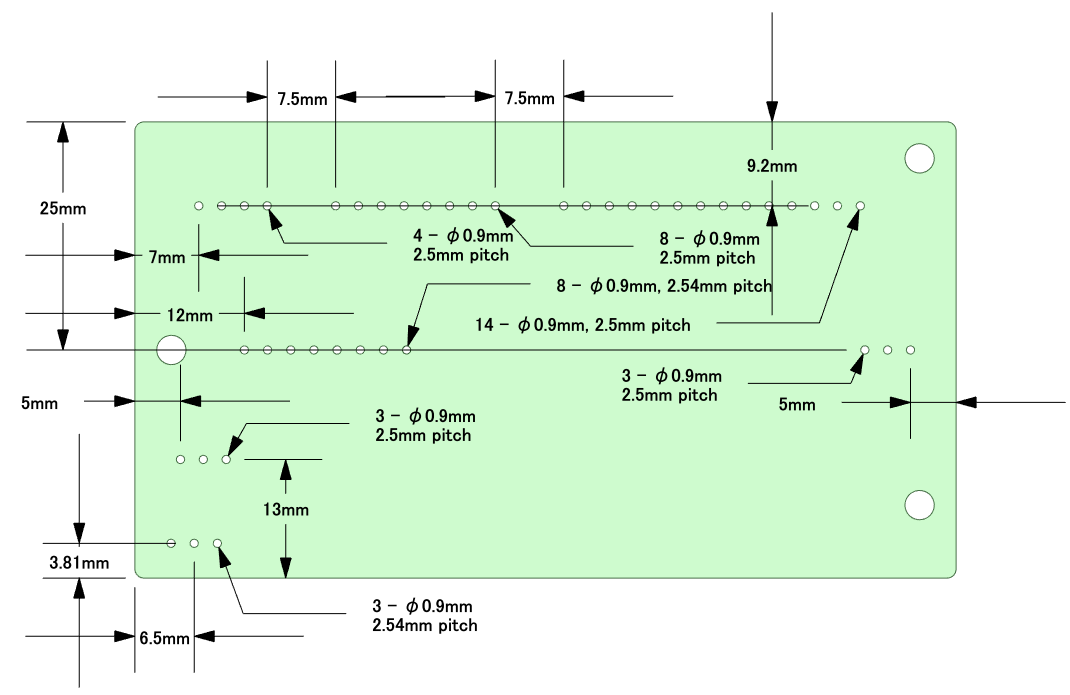

| BD3 | CC-218 MCU | PCB3 Manufactured by maker |

Double-sided thru hole PCB 1.6 x 90 x 50mm |

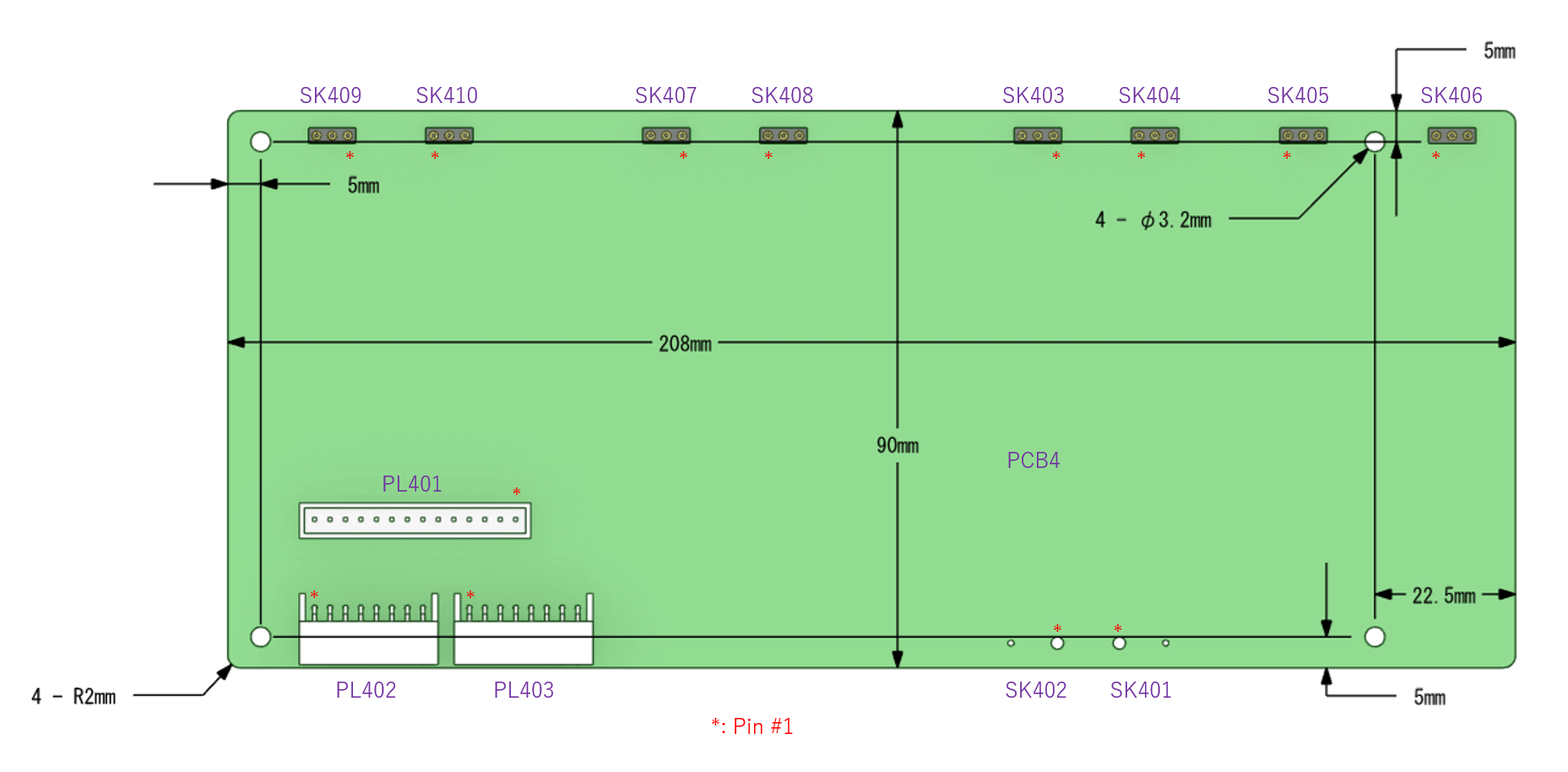

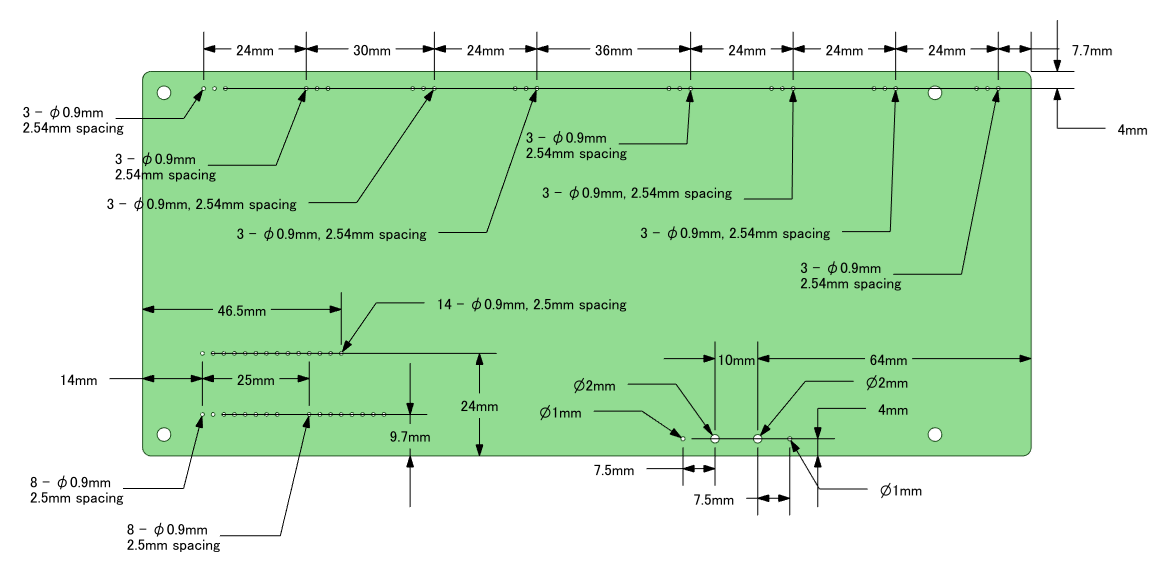

| BD4 | CC-218 VOL | PCB4 Manufactured by maker |

Double-sided thru hole PCB 1.6 x 208 x 90mm |

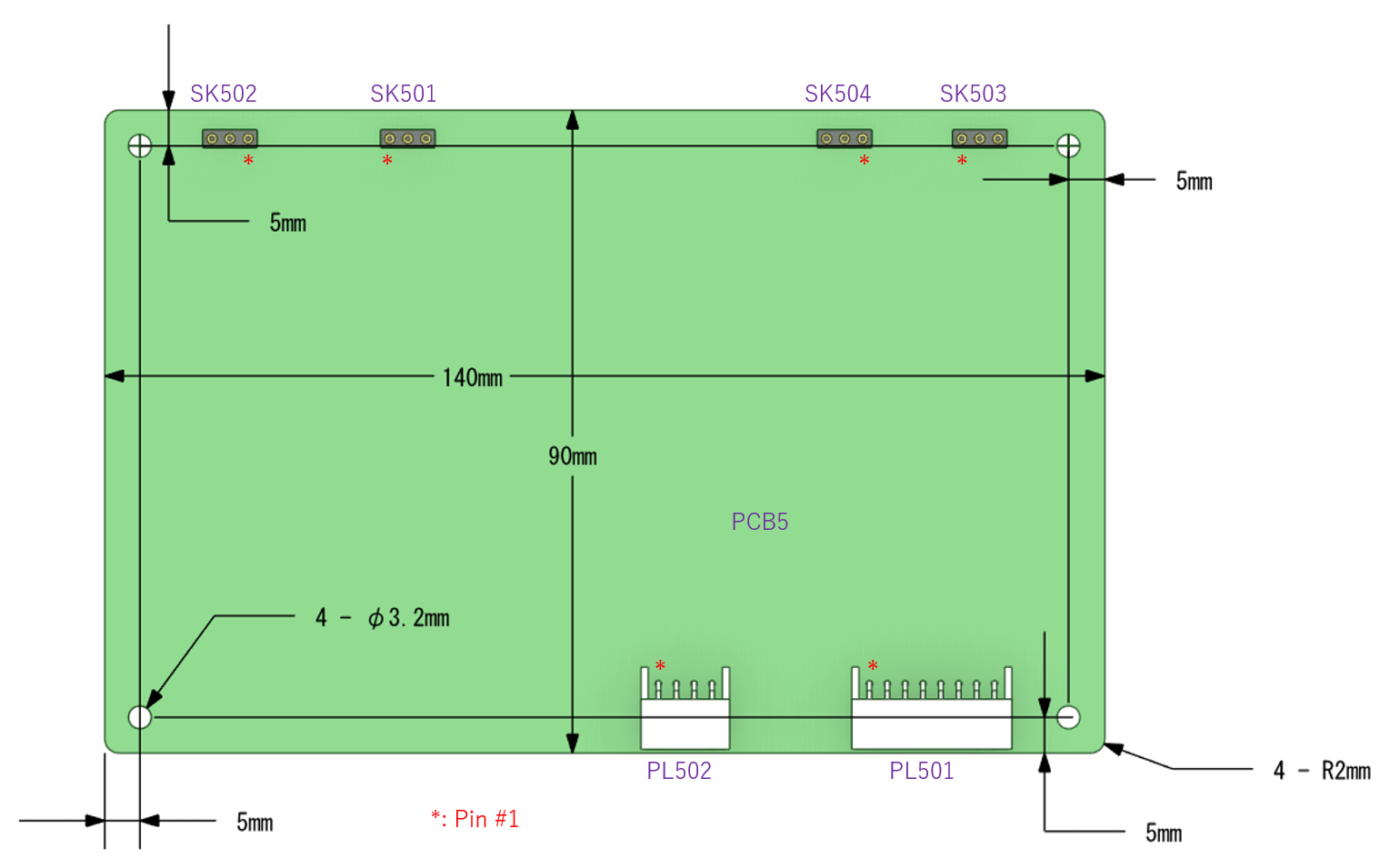

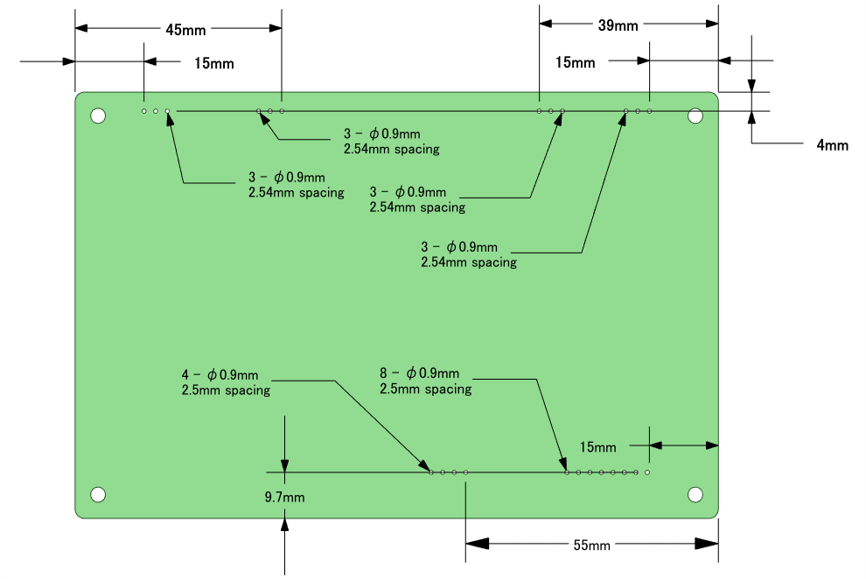

| BD5 | CC-218 EQ | PCB5 Manufactured by maker |

Double-sided thru hole PCB 1.6 x 140 x 90mm |

All the connectors used for internal connections are JST (Japan Solderless

Terminal) XH series connectors. These were also used in the MV-217, so

I already have the tool and am familiar with their use.

Connections between Back Panel connectors and the PCBs will be made using

either 0.5mm gold-plated OFC wire or 1/4W resistors. The connector side

will be soldered, while the PCB side will be connected via pin sockets.

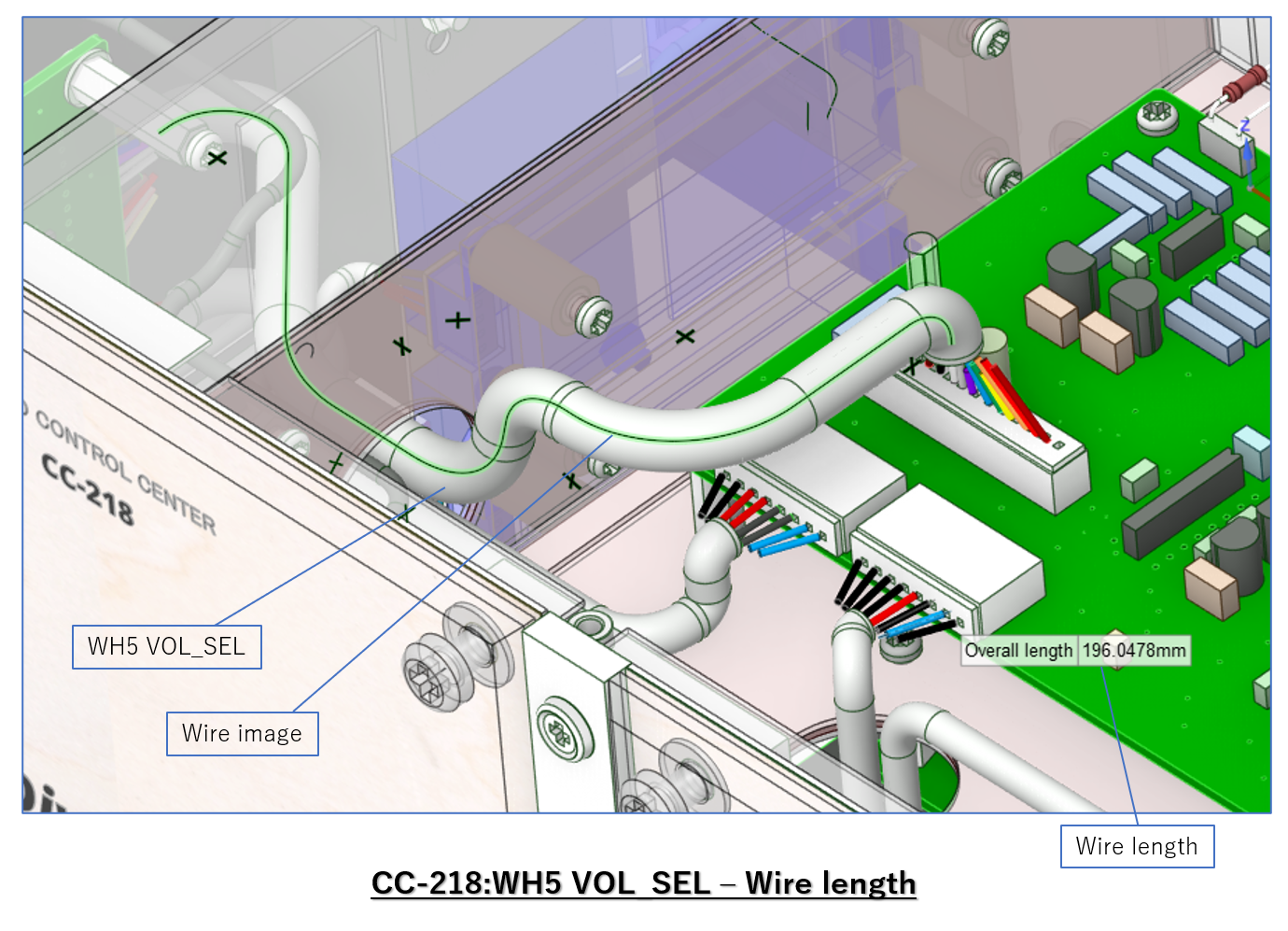

Wiring design

The table below shows the wires used on CC-218.

| Use | Type/spec | Gauge | Color |

|---|---|---|---|

| Power supply Primary |

UL1015 Rating: 600V |

AW18 | Earth:Green, Line:Black, Neutral:White (Conforming to standard) |

| Power supply Secondary |

UL1007 Rating: 300V |

AW22 | GND:Black, Positive supply:Red, Negative supply:Blue |

| Board to board Digital |

UL1007 Rating: 300V |

AW22 | P1: Brown, P2: Red, ... (The color corresponds to pin number of connector) |

| Board to panel Digital |

Canare L-2B2AT Dual-core coaxial |

AWG25 (core) | Grey |

| Analog | Neglex 2520 Single-core coaxial |

Sub-miniature | L-ch: white R-ch: Red |

| Board to panel Analog |

Amtrans AMOFC-GMK-05FC |

0.5mm dia. OFC |

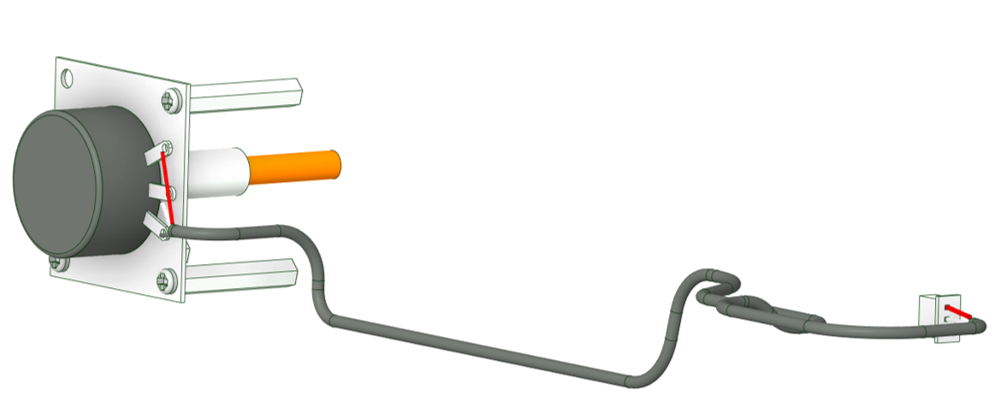

I used mechanical CAD (DesignSpark Mechanical) to design wiring.

Here's an example: The CAD shows routing of the wire harness (WH5 VOL_SEL)

and its length.

In the above example, CAD calculates the wire length and the result is

196mm. Some margin has to be added to this length to connect the wire to

the connector.

I added 40mm and the total length becomes 236mm in case of WH5.

The way of connecting the boards to the RCA jacks in Back Panel is one of the unique idea employed in CC-218; using 0.5mm gold-plated OFC wires or resistors instead of wire harnesses. One end of the wire/resistor is soldered to the RCA jack while the other end is inserted into the pin socket on the board.

For further details of layout and wiring, see the following PDFs.

<Design document of layout and wiring: CC-218_Design_LayoutWiring.pdf>

<Wire harness assembly manual: CC-218_Design_WireAssy.pdf>

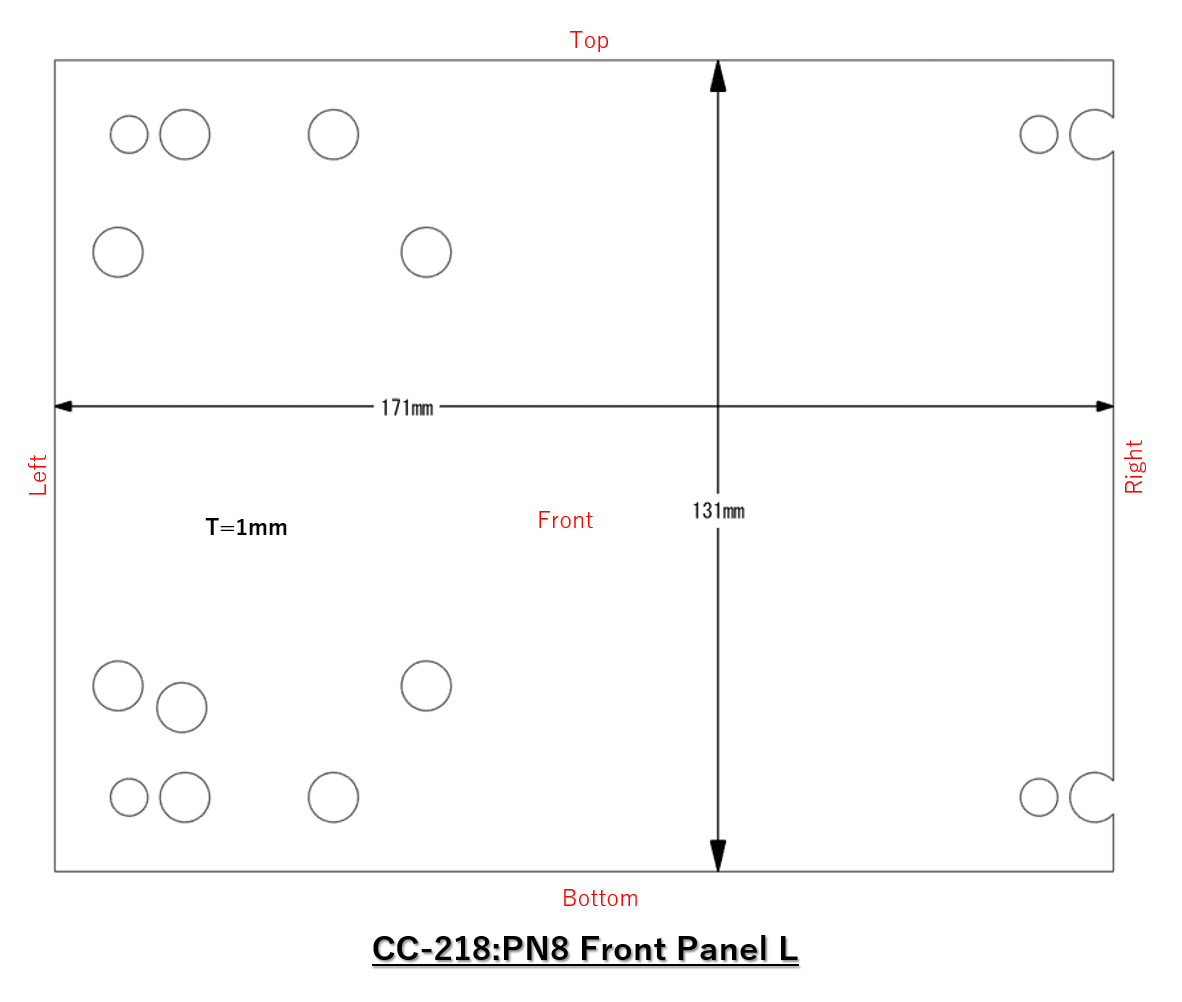

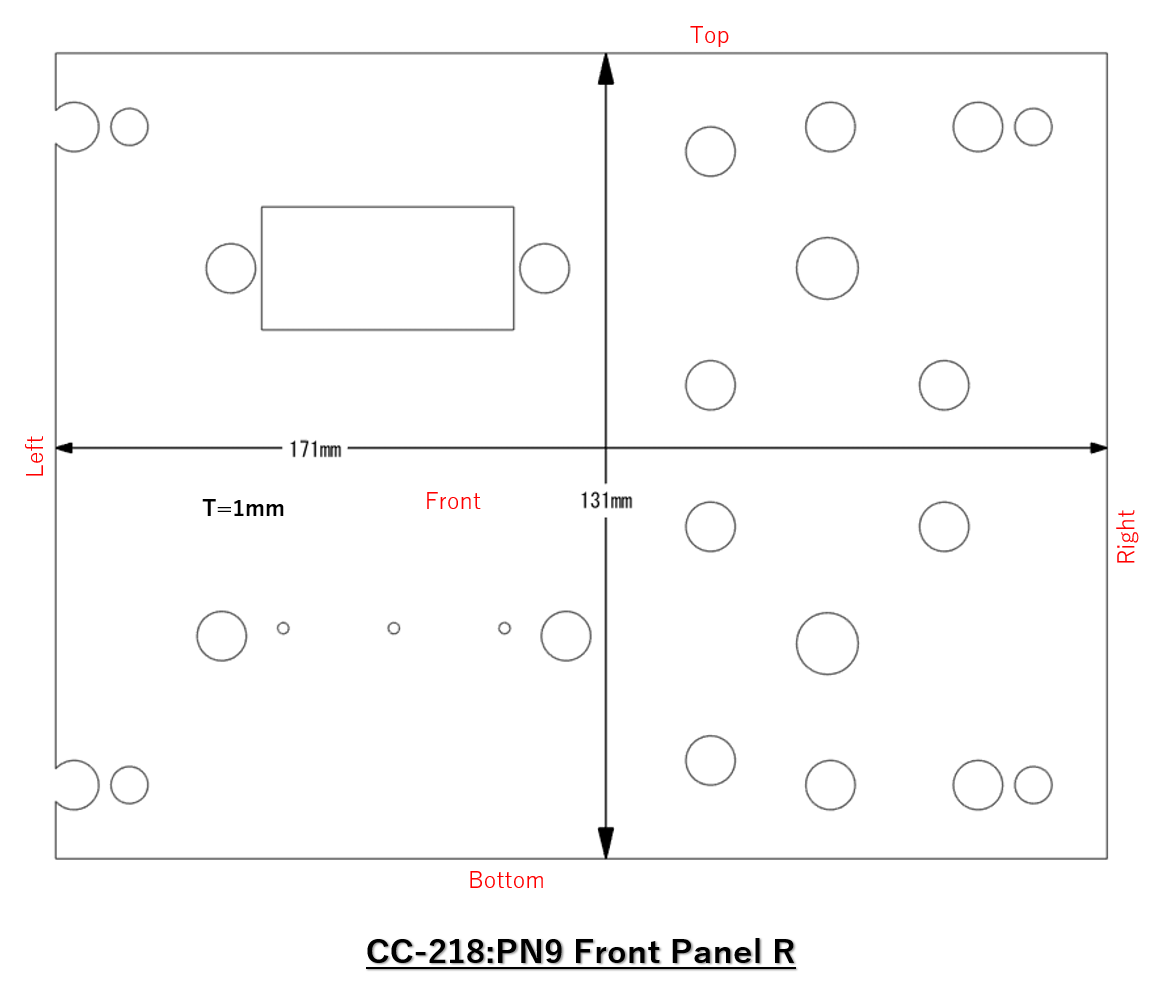

Design of outer panels

Now that the layout and wiring design is done, the design of the out panels should be fixed.

Front Panels

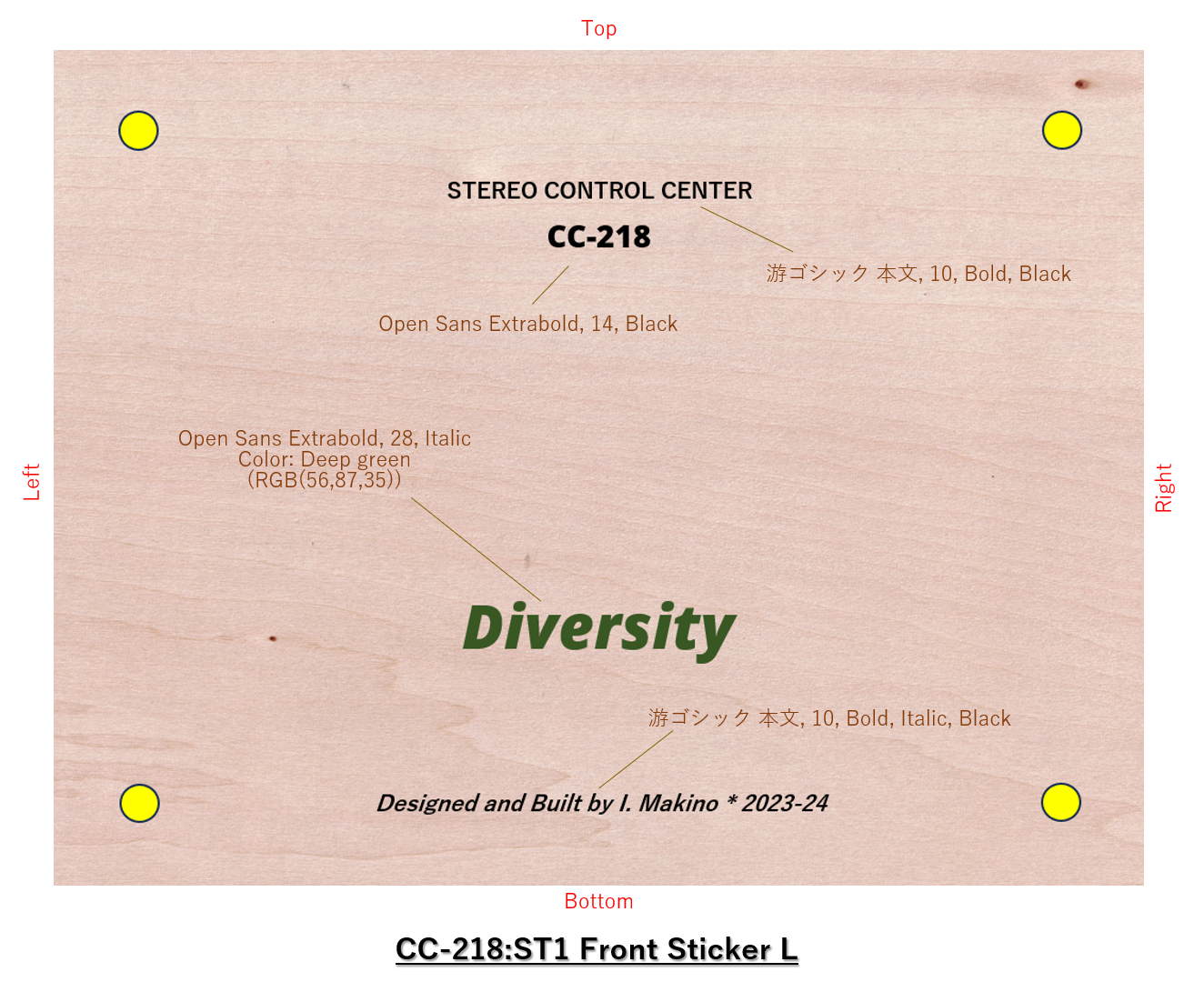

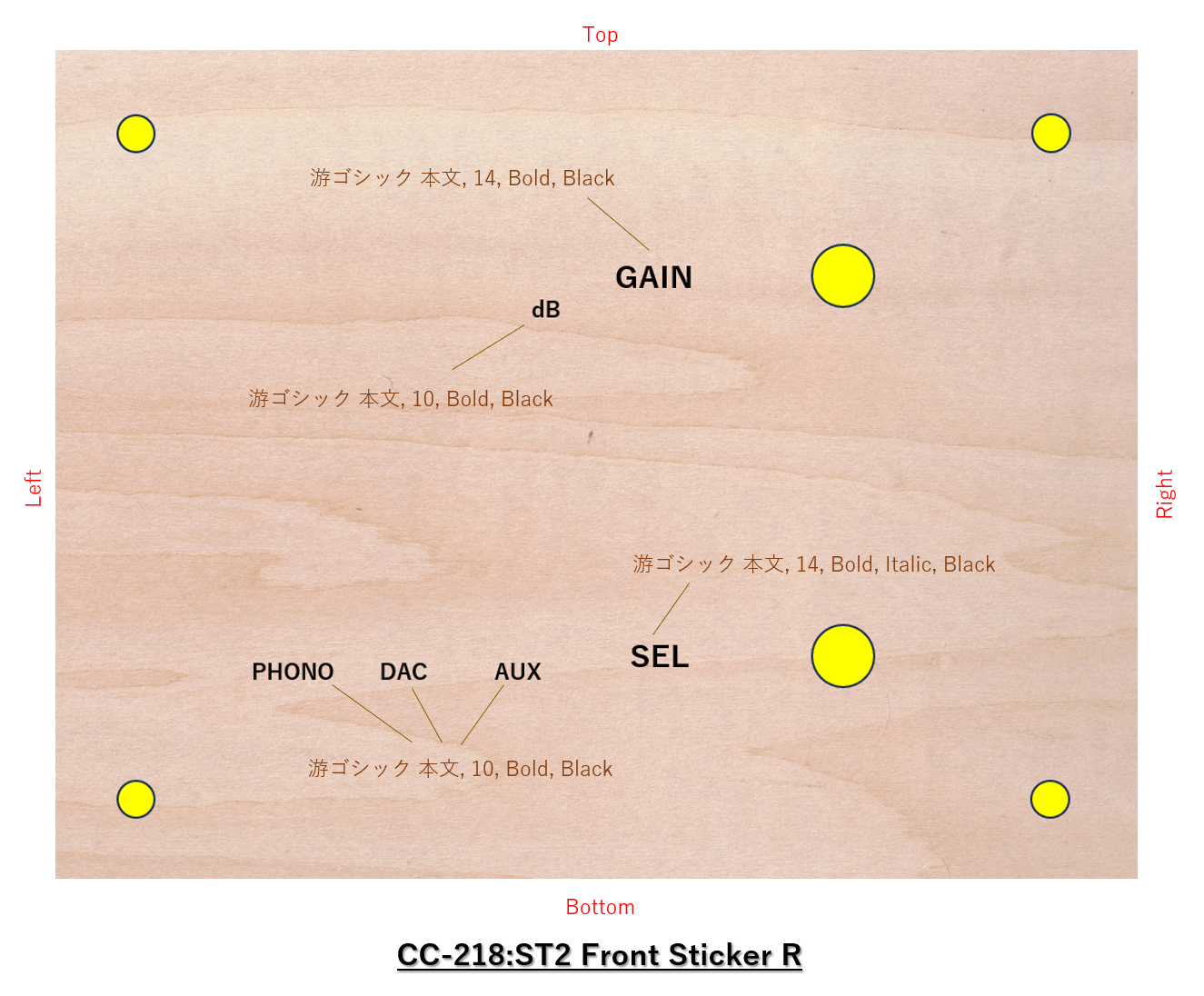

Here are figures of outlines of Front Panels and Front Stickers. For detailed drawings, see "metalwork manual" and "finish manual".

|

|

| Front Panel L (PN8) 1mm-thick aluminum panel |

Front Panel R (PN9) 1mm-thick aluminum panel |

|

|

| Front Sticker L (ST1) A-one 28874N |

Front Sticker R (ST2) A-one 28874N |

Back Panels

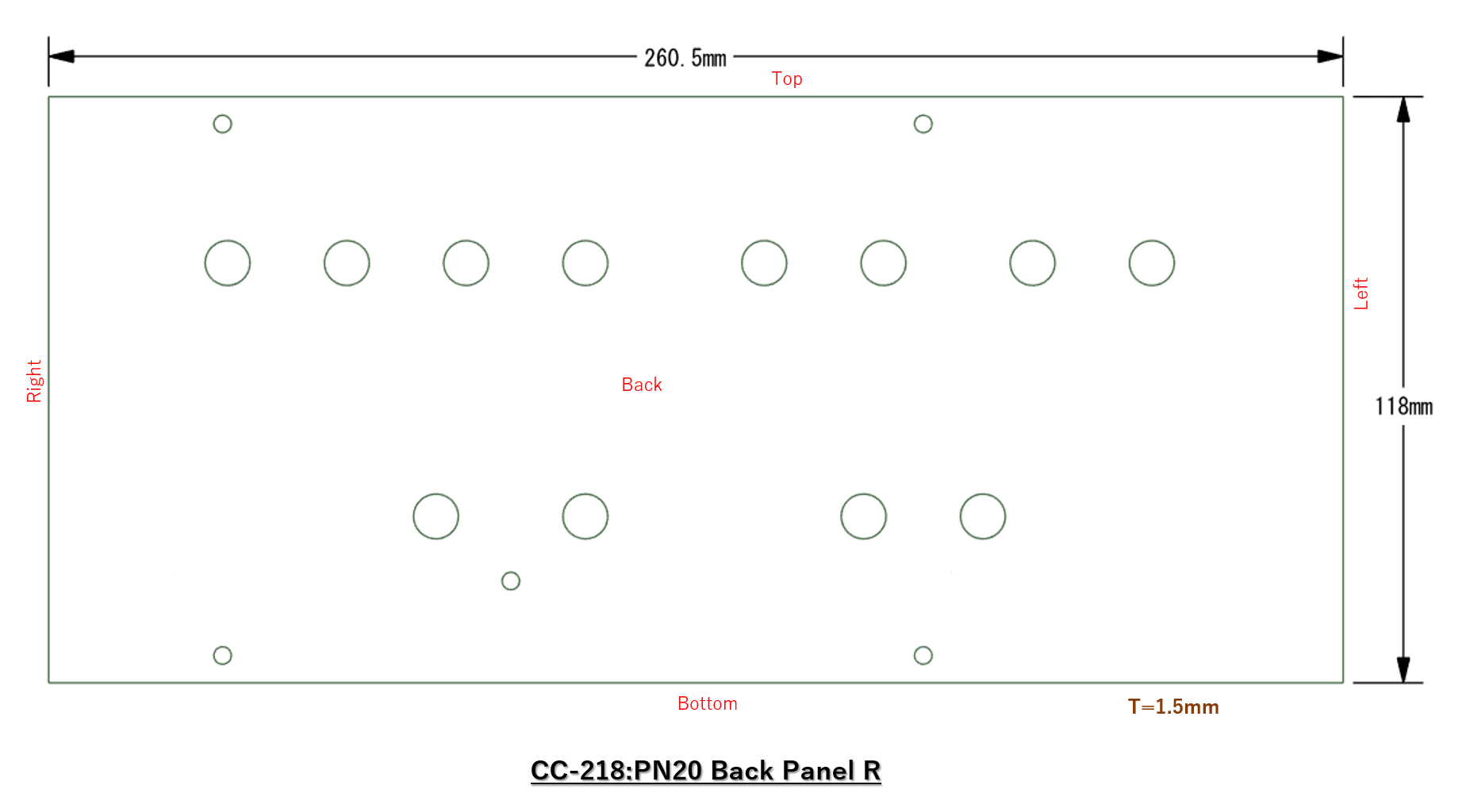

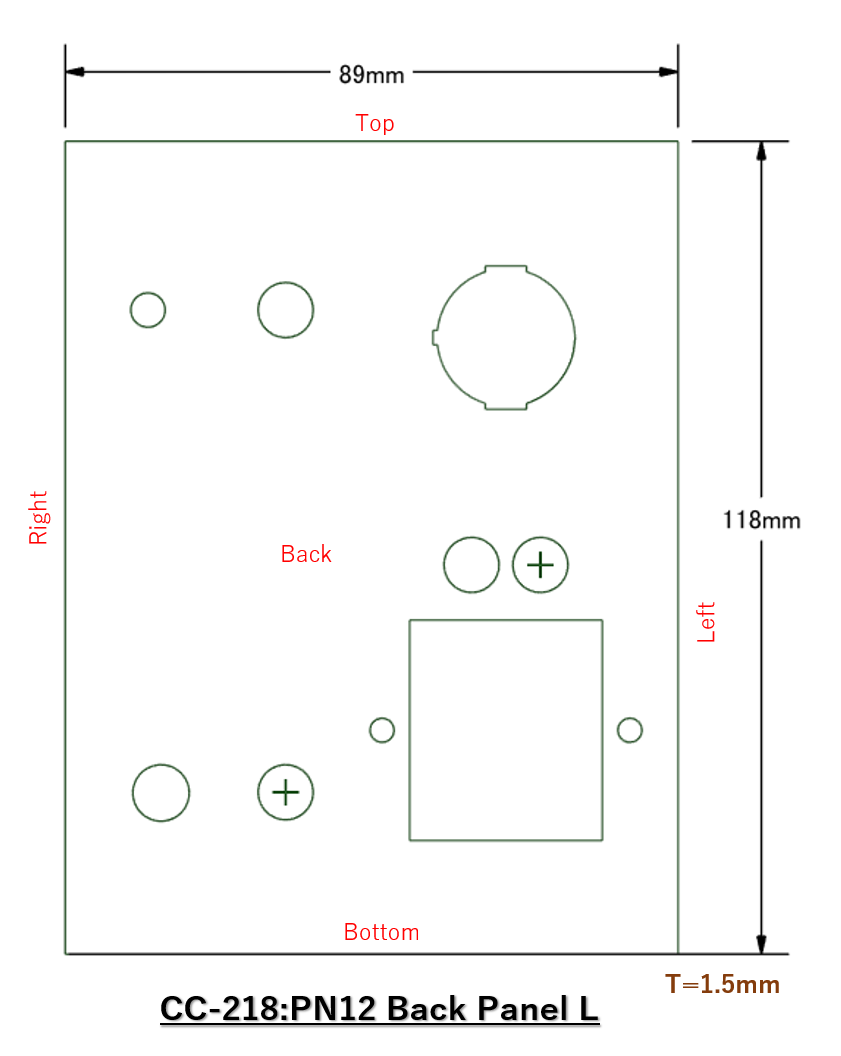

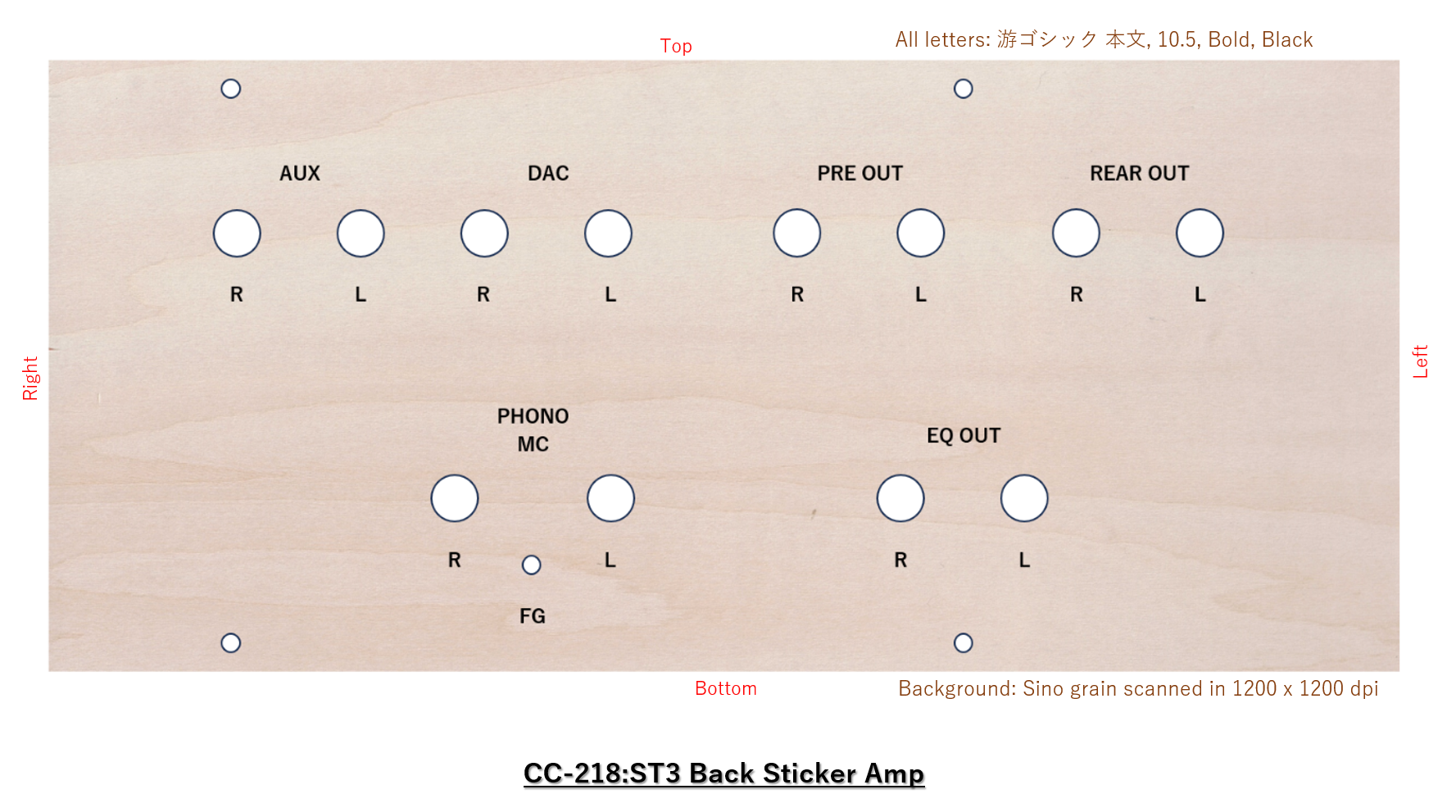

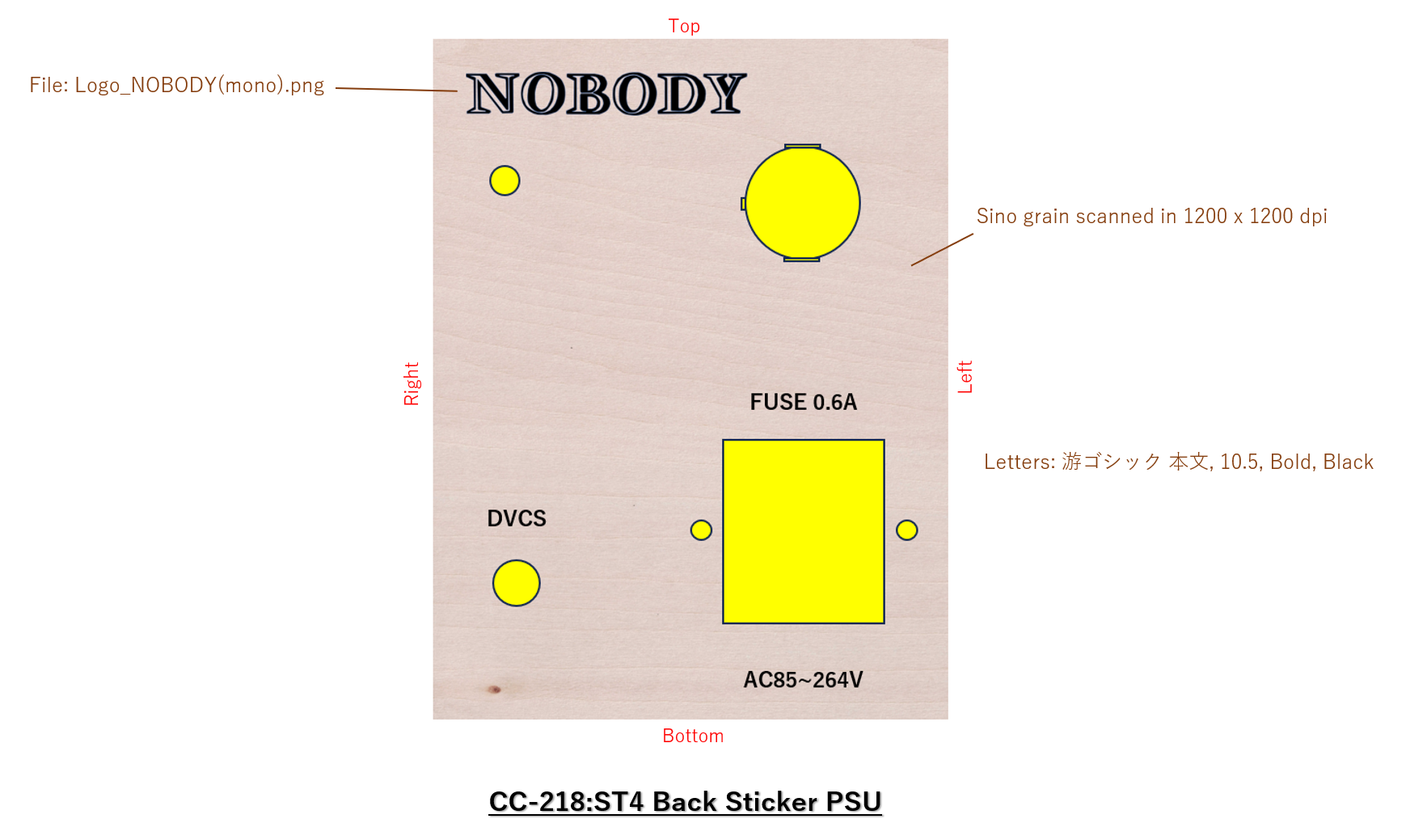

Here are figures of outlines of Back Panels and Back Stickers. For detailed drawings, see "metalwork manual" and "finish manual".

|

|

| Back Panel R (PN20) 1.5mm-thick aluminum panel |

Back Panel L (PN12) 1.5mm-thick aluminum panel |

|

|

| Back Sticker Amp (ST3) A-one 28874N |

Back Sticker PSU (ST4) A-one 28874N |

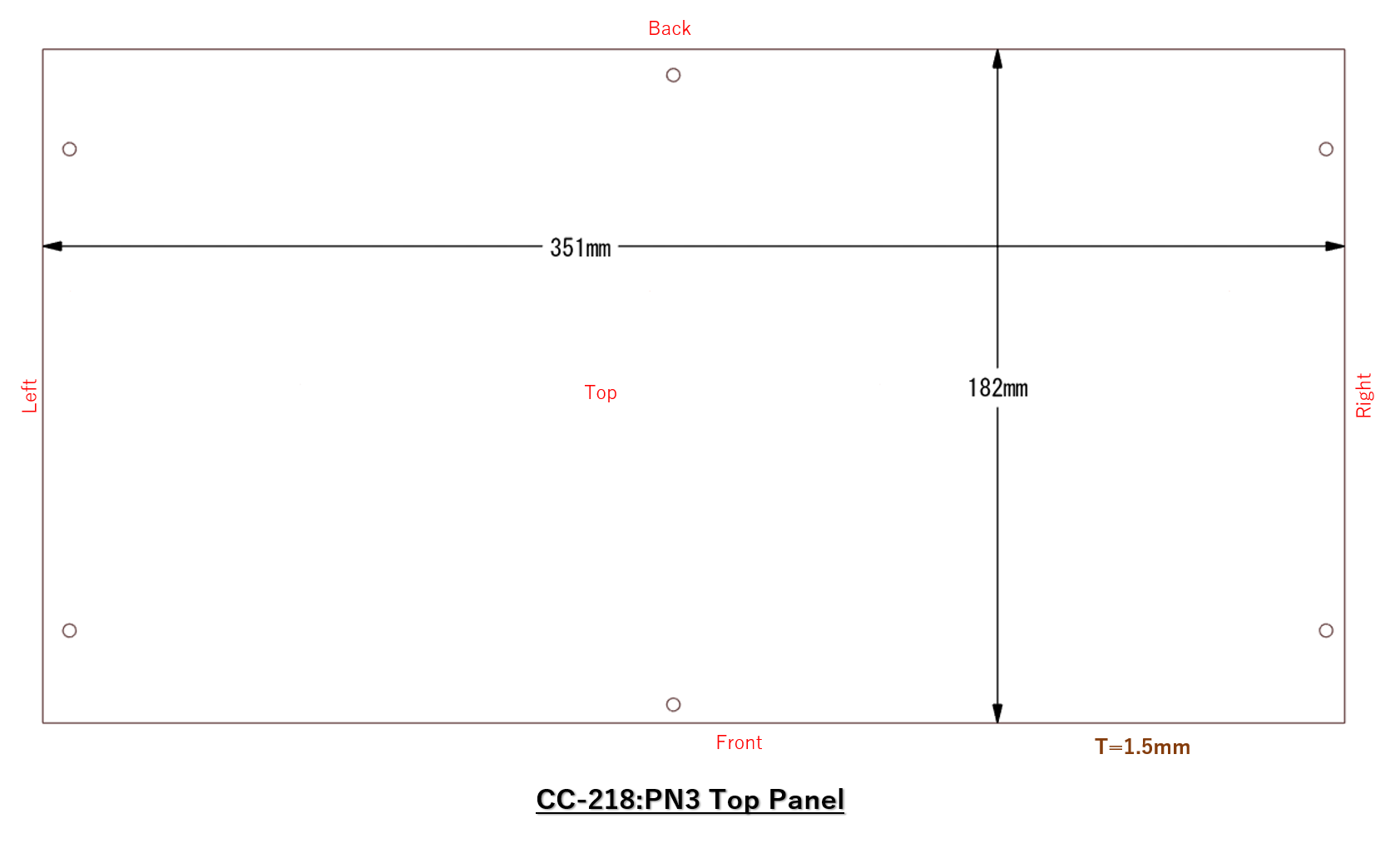

Top Panel

Here are figures of outlines of Top Panel and Top Sticker. For detailed drawings, see "metalwork manual" and "finish manual".

|

| Top Panel (PN3) 1.5mm-thick aluminum panel |

|

| Top Panel w/ Top Stickers (ST5,ST6) affixed on it ST5: Block Diagram, ST6: Level Diagram ELECOM EDT-STSC |

Drawings of Mechanical Design

Here's the metalwork manual:

<Metalwork manual: CC-218_Metalwork.pdf>

Here's the manual for processing nonmetalic materials:

<Manual for nonmetalic parts: CC-218_Woodwork.pdf>

Temporary assembly of the enclosure is necessary because the handmade mechanical

parts have dimensional errors. During the temporary assembly, each part

is to be touched up by files.

<Manual for temporary assembly: CC-218_PreAssy.pdf>

After the temporary assembly, disassemble the enclosure, and clean the

parts . After that, finish the outer panels and knobs.

<Finish manual: CC-218_Finish.pdf>

I found some bugs during creating these manuals, and revised the mechanical

design.

The purpose of the manuals is to make the labors more efficient. In addition,

creating manuals helps the desinger to find bugs because that's a kind

of simulation.

Thanks to the manuals, I could avoid unnecessary reworking in both making

parts and temporary assembly.

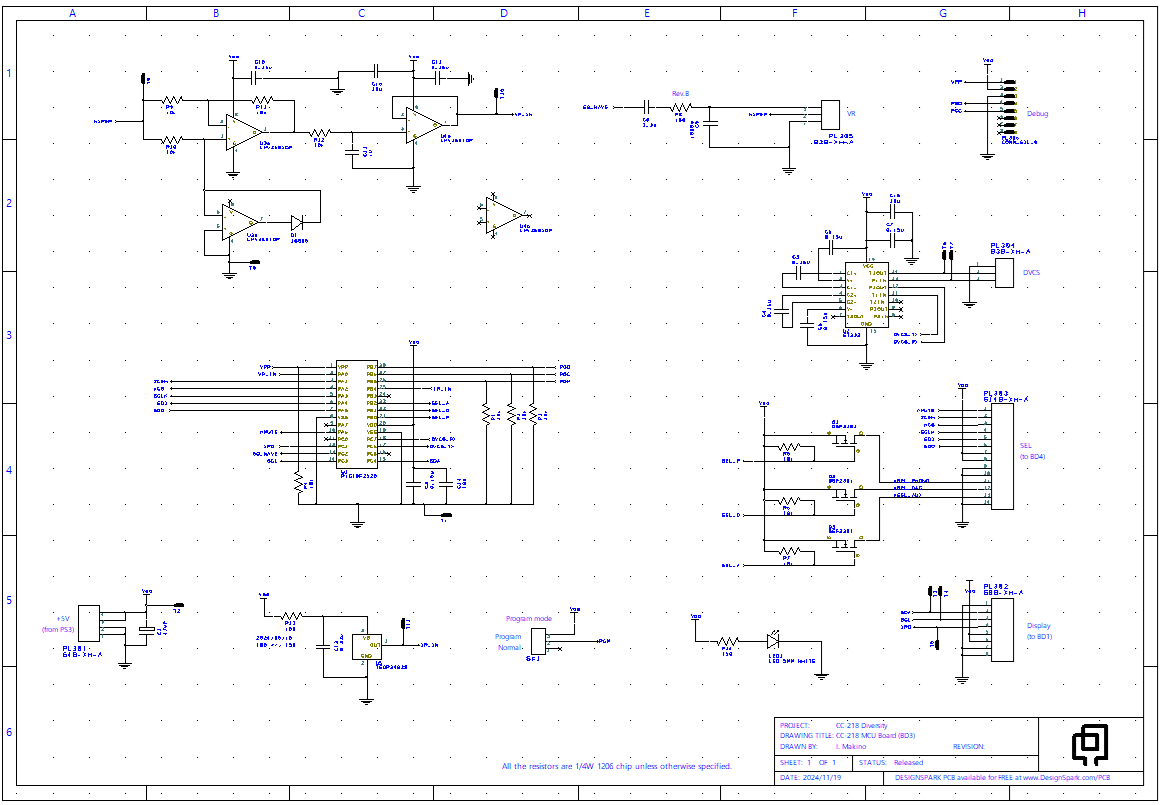

Circuit Design

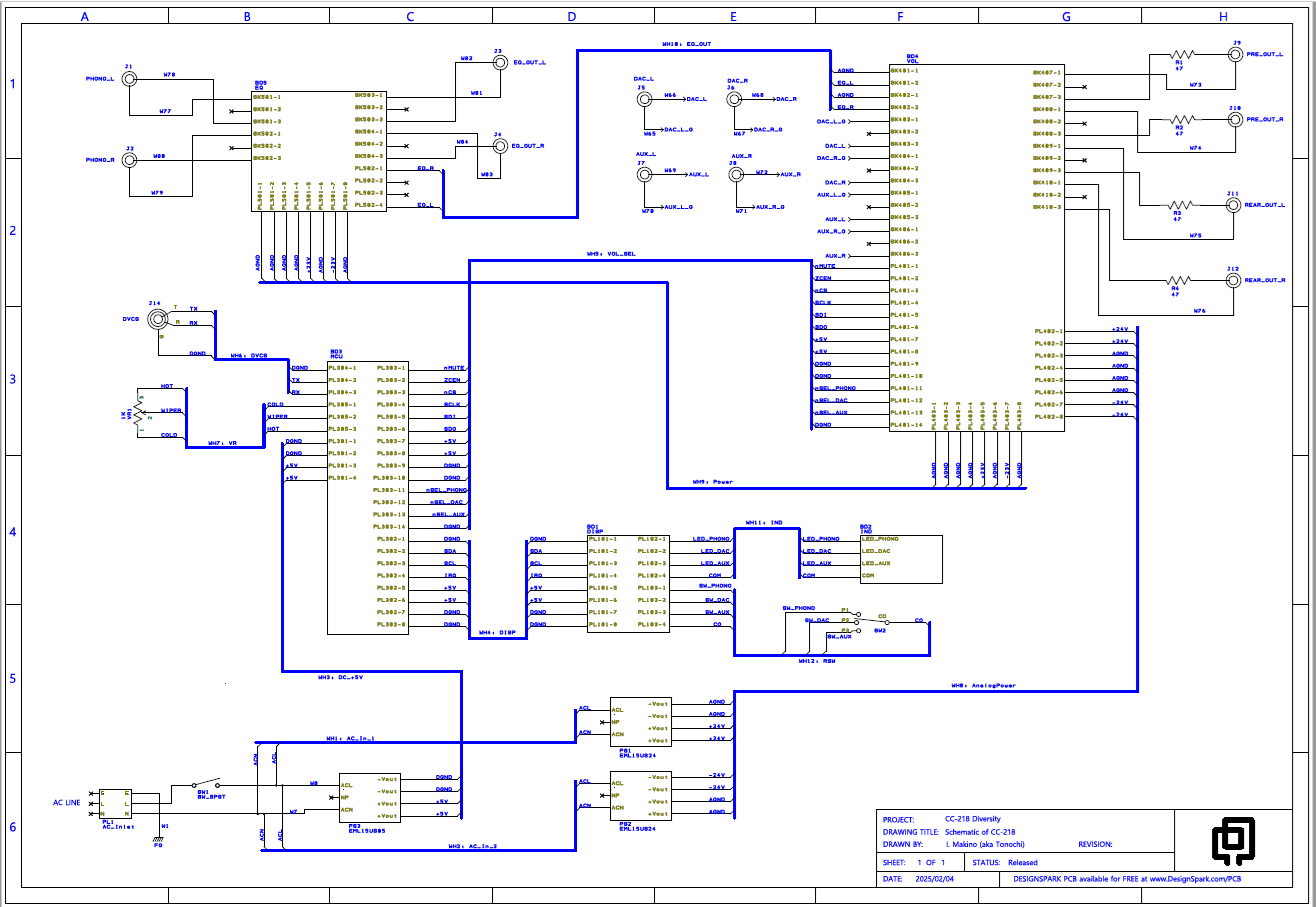

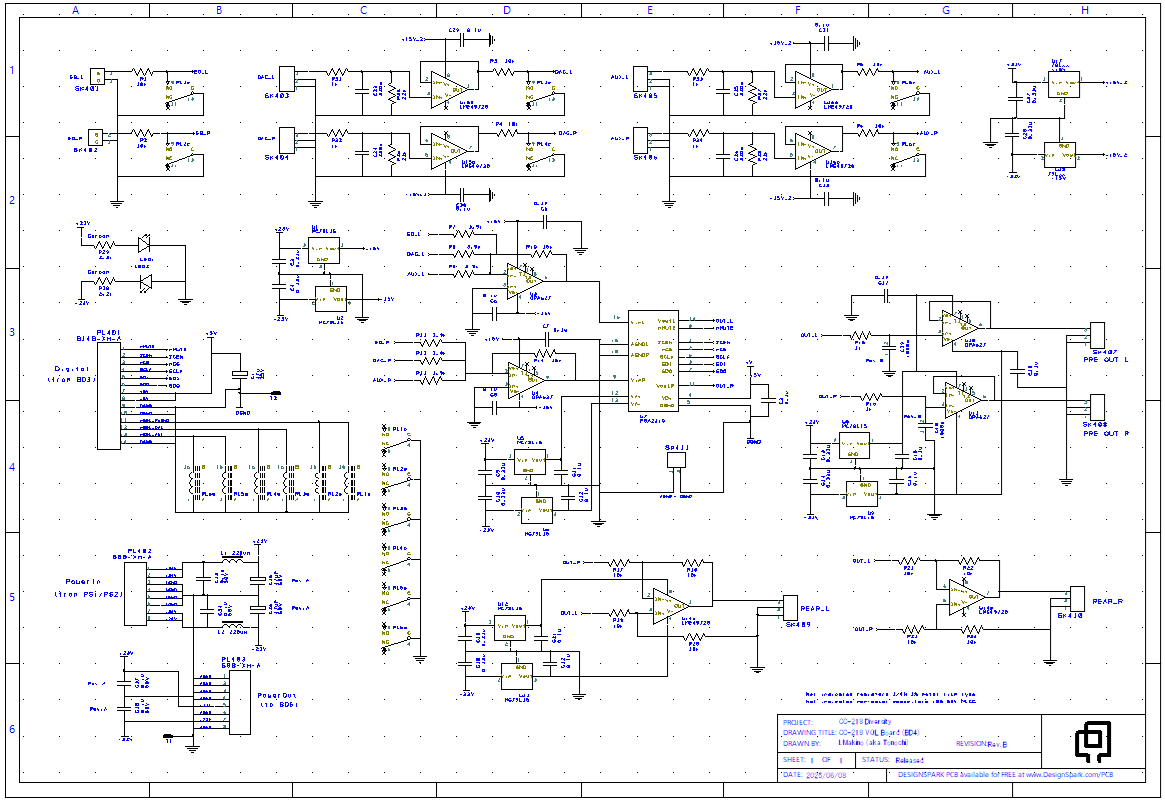

The figure below shows the total schematic of CC-218.

Note that the output resistors (R1~R4) are not on the board (BD4) but they are placed between the board and RCA jacks (PRE OUT, REAR OUT). The resistors are used to connect the output signals of the board to the RCA jacks instead of wire harnesses. So, the schematic of CC-218 VOL (BD4) doesn't include the output resistors.

From now on, circuit design will be carried out on board by board basis.

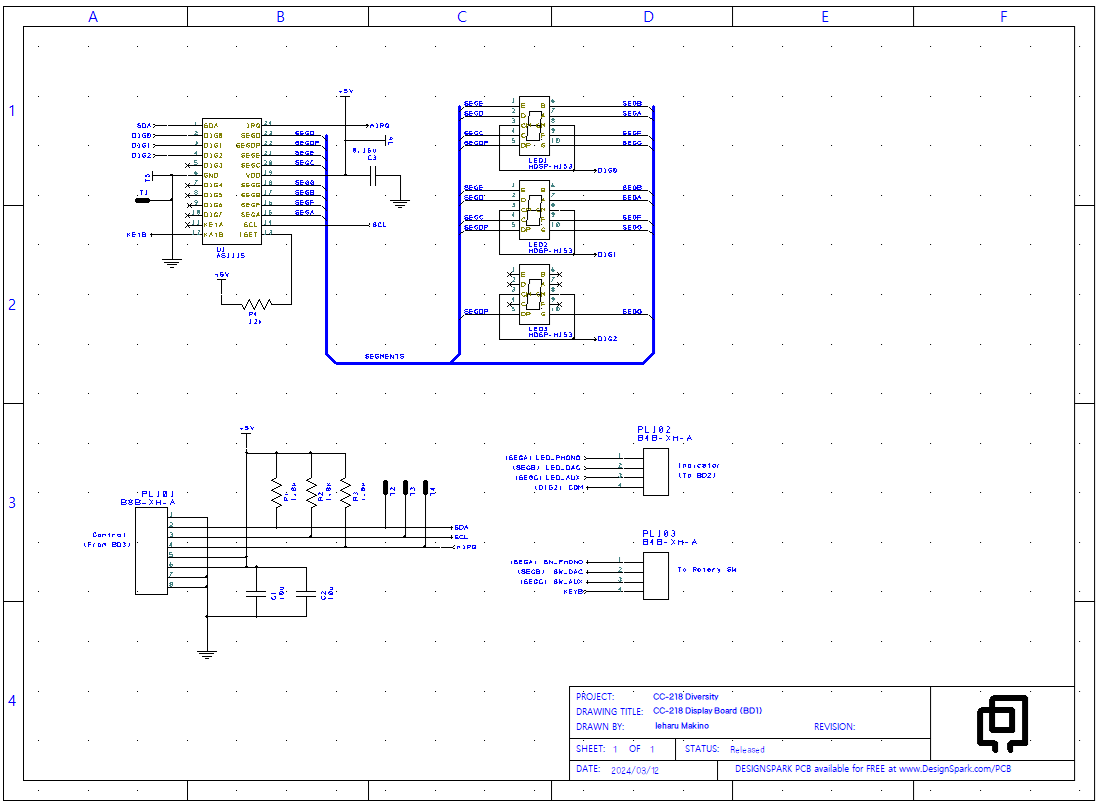

BD1: CC-218 DISP

Display Board that includes three units of 7-segment LEDs (hearafter 7-seg)

and a display controller chip.

<CC-218 DISP specifications: CC-218_DISP_Spec.pdf>

The display controller used is Austria Microsystems (AMS) AS1115. The package type is QSOP-24. It can control up to eight digits of 7-segment displays and read up to 16 switches. Although reading switches may seem simple, it actually requires rather troublesome processing, such as debounce handling. AS1115 performs debounce and notifies MCU via an interrupt when it detects a change in switch state. This eliminates the need for MCU to constantly monitor the switch states.

I had wanted to use orange 7-seg, but chose the ordinary red 7-seg as explained in "Appearance Design". It's Broadcom HDSP-H153.

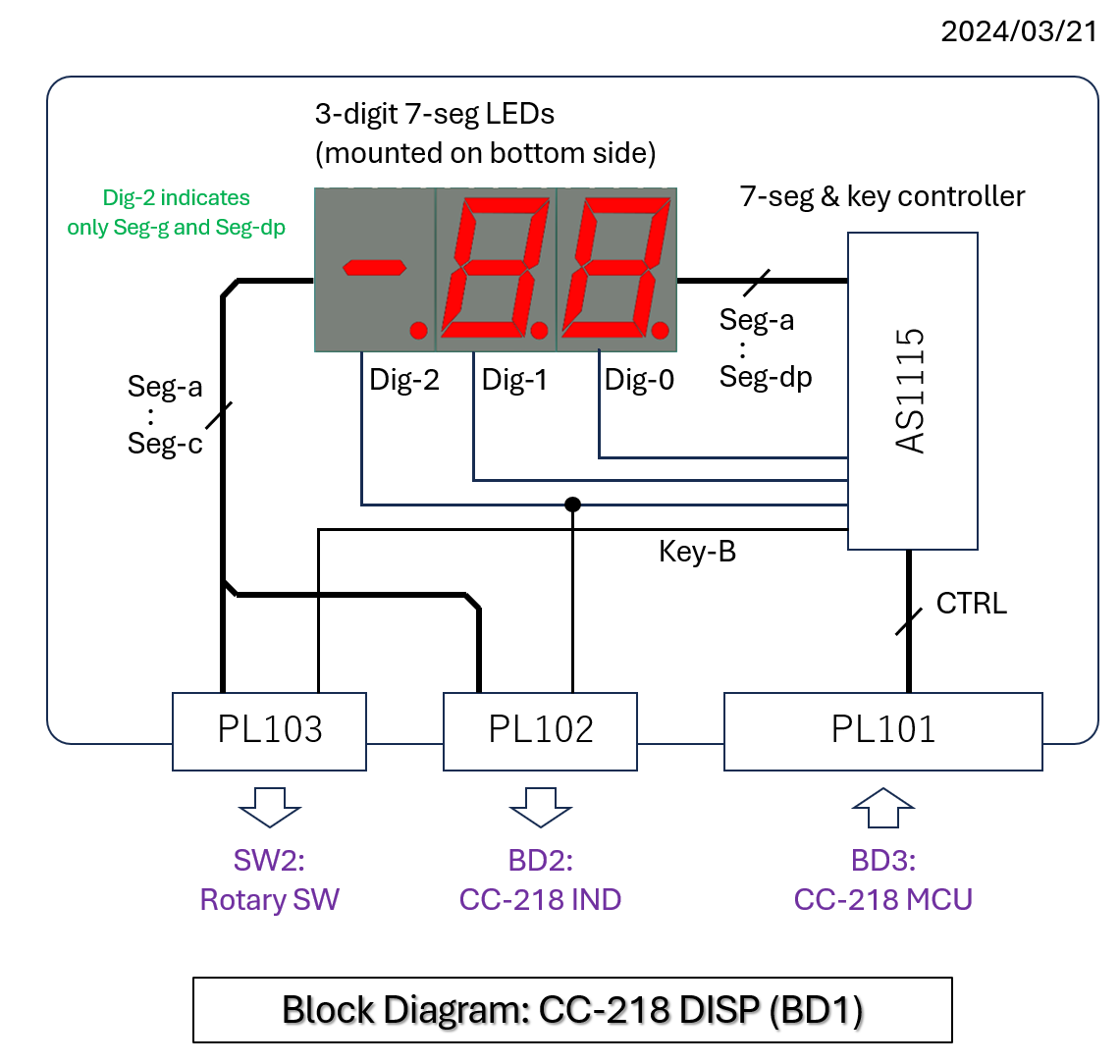

The block diagram of this board is shown below.

The connector PL101 receives not only control signals but aslo DC power supply from the controller board (CC-218 MCU).

The most significant digit of the numeric display (Dig-2) is used only

to display the minus sign ‘-’ (Seg-g) and the decimal point ‘.’ (Seg-dp).

Seg-a of Dig-2 is used as PHONO Indicator, Seg-b as DAC Indicator, and

Seg-c as AUX Indicator.

The indicators (LED) are mounted on Selector Indicator Board (BD2 CC-218

IND). The signals for the LEDs are output to BD2 via PL102.

The signals for reading the switches are connected to Rotary SW (SW2) via PL103.

The schematic of this board is shown below.

The current-limiting resistor R4 for the LEDs is set to 12 kΩ, resulting in IF (forward current) of 40 mA. Though this may seem like a large current, the LED light needs to pass through the stickers (ST1, ST2), and since the duty cycle is 33%, I concluded that this level of current was necessary.

A rotary SW (Fujisoku SRF113-Z) is used for the selector switch. Since SRF113-Z is a non-shorting type, N-key rollover feature is not required to read the on/off state of the contacts. Therefore, diodes for preventing reverse current are omitted.

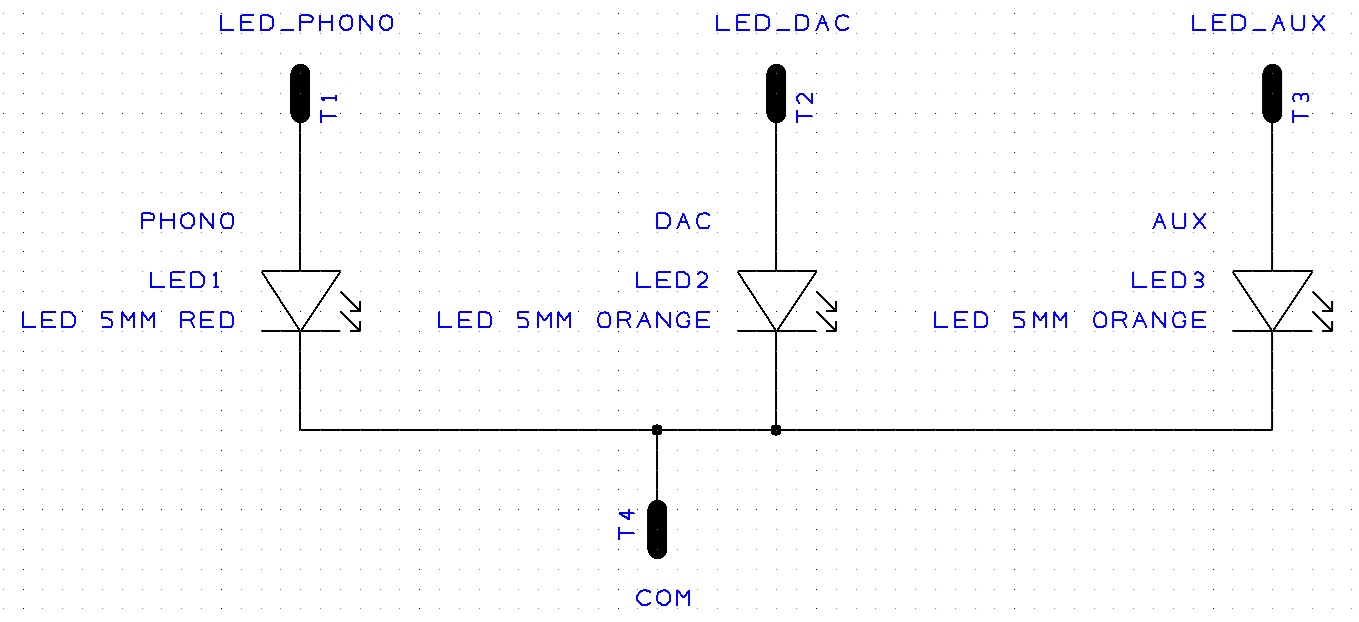

BD2: CC-218 IND

Selector Indicator Board that contains only three LEDs.

BD2 is the only board that uses a universal PCB among the boards in CC-218.

BD3: CC-218 MCU

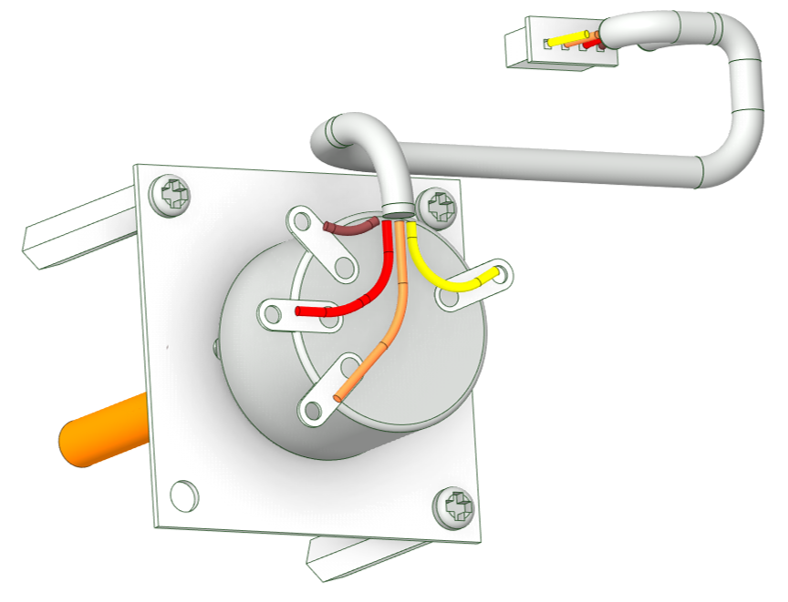

Controller Board that includes MCU chip, relay drivers, VR interface, and

so on.

<CC-218 MCU Specifications: CC-218_MCU_Spec.pdf>

I selected PIC18F2520 for the MCU chip. The reason of the selection is

mentioned in "Key Parts and Materials".

The package is 28P DIP.

For the relay driver, I chose the GSF2301 P-channel MOSFET from Good-Ark Semiconductor. It has a low on-resistance of 110 mΩ, and a built-in protection diode. So it is easy to use. Another advantage is its low price—just 44 JPY per unit.

A 10 kHz square wave is output to the variome (VR1), generated using MCU’s PWM function. To prolong the contact life of the VR, the output is AC-coupled using a coupling capacitor to remove the DC component. The voltage divided by the VR is then rectified, smoothed, and supplied to the analog input terminal of MCU.

For the infrared receiver (IR receiver), I selected Vishay TSOP34838, but

this turned out not to be the best choice. It’s an older model that is

nearing the end of its production, and I should have opted for the improved

version, TSOP34438, instead. The TSOP34438 is designed to be more resistant

to infrared noise from sources such as inverter-based fluorescent lights.

As of Julyl 2025, it has been in use for about six months, and so far its

operation has been stable. In fact, the air conditioner remote control

used in the same room has far more errors. Since the TSOP34838 and TSOP34438

are pin-compatible, I could still switch them out if necessary, but it

doesn’t seem needed at this point.

At the start of the project, I had very little knowledge of infrared remote

control specifications. , I selected this IR receiver based on the knowledge

I learned from a reference [Ref-42, pp.263~274]. With it, the system can

receive infrared signals from all Japanese-made TV remote controls.

<Reference list>

For the rectifier circuit, I chose LMV358IDR, a single-supply, rail-to-rail type op amp. To avoid voltage drop caused by the forward voltage (VF) of the rectifier diode, I contrived this rather complex circuit.

I used a circuit simulator Micro-Cap Ver.12 for debugging this circuit.

<Circuit design document: CC-218_MCU_CircuitDesign.pdf>

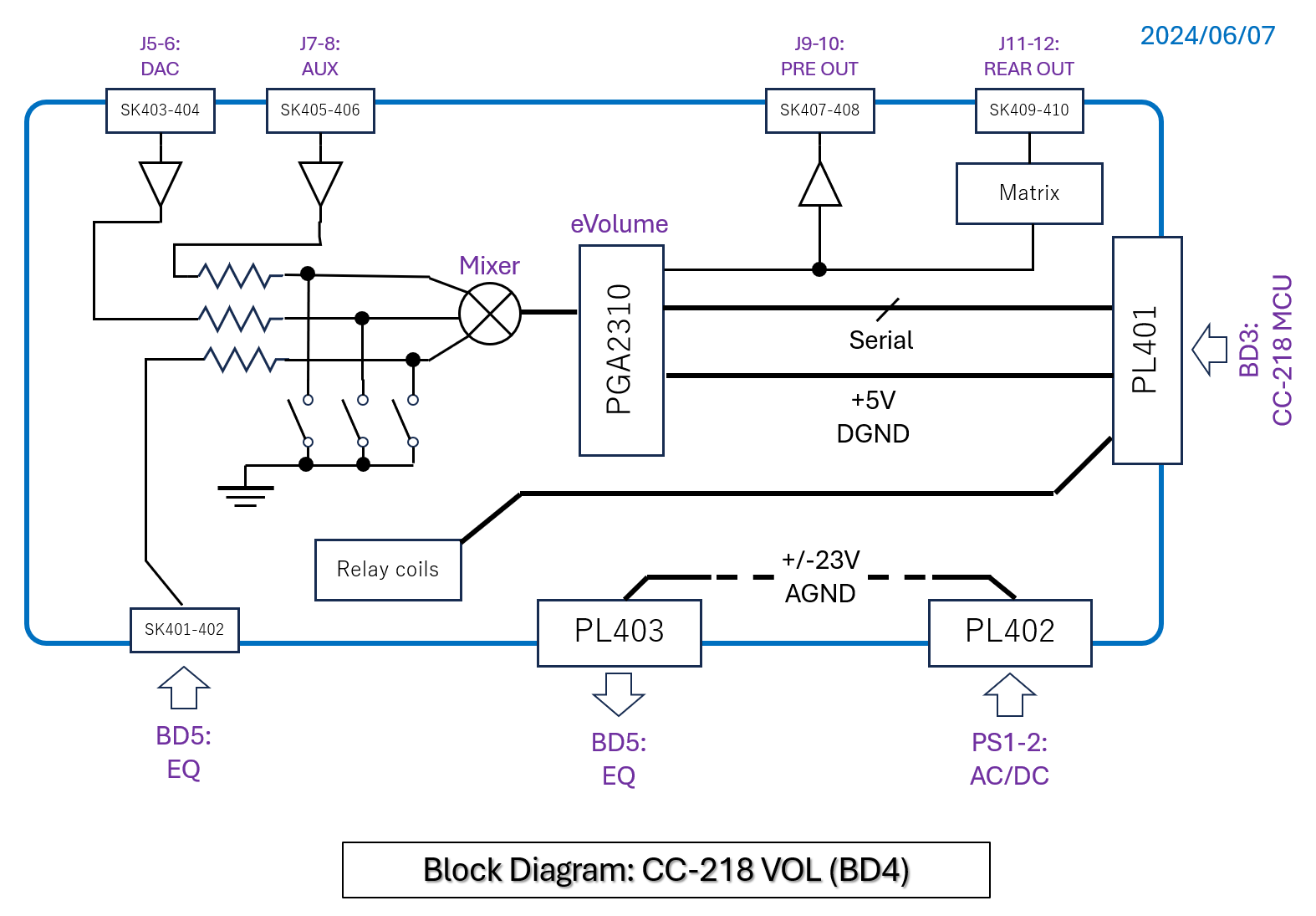

BD4: CC-218 VOL

The selector/volume board that includes the eVolume chip (PGA2310) and

the selector relays.

It's the only board in CC-218 which is composed of both digital and analog

circuits.

<CC-218 VOL Specifications: CC-218_VOL_Spec.pdf>

The selector uses a shunt method, so the audio signal does not pass through

any contacts. Signals from unselected sources are grounded to prevent them

from being output.

I also considered a method using semiconductors as switches (analog switches),

but I couldn’t find a suitable device, so I settled on the shunt method.

In designing this selector circuit, I referred to the book written by Mr.JLH

(John Linsley Hood) (Ref-37, pp.136~137)

<Reference list>

The schematic below is Rev.B (the final revision). Two issues discovered during testing were corrected, resulting in this Rev.B.

For the selector relay, I chose the Omron G5V-2 mini relay. I also considered using low on-resistance MOSFETs, but relays are easier to use since they are non-polarized, so I went with that option. I am aware of the potential for aging-related degradation. While increased on-resistance could cause slight crosstalk between sources, this only becomes an issue when multiple sources are played simultaneously, which I consider an acceptable shortcoming.

In the previous project (PA-210), I used micro relays, but that was a mistake based on a misunderstanding.

I had simply assumed that relays with smaller form factors were better

suited for switching small signals.

Relay contacts can have a shortened lifespan if the current is too low.

Audio signals generally carry very small currents. For example, applying

1V across a 10kΩ load results in a current of just 0.1 mA, and it's rare

for audio signals to exceed that. Relays used for switching audio signals

must be able to handle low currents.

I considered two candidates: G5V-1 and G5V-2. Both are manufactured by

Omron. G5V-1 is a micro relay, and G5V-2 is a mini relay (with larger form

factor than G5V-1).

The current range for G5V-1 is 1mA ~ 1A, whereas G5V-2 can handle 10µA

~ 2A. As you can see, larger relays tend to support a wider range of current

and are more capable of handling low current. Based on this reasoning,

I chose G5V-2.

According to the datasheet, the contact resistance of G5V-2 is 50mΩ. Based

on that value, the crosstalk between sources calculates to about –94dB.

As the contacts age, this value will worsen. Some amplifier enthusiasts

might find this unsatisfactory, but since I’m not one of them, I have no

intention of chasing excessive performance—I’m satisfied with this.

<Circuit design document: CC-218_VOL_CircuitDesign.pdf>

The revisions are summarized below. For details, please refer to “Measurements and Improvements.”

Rev.A: A noise filter was added to the DC power line, which I had forgotten

in the original design. The GND wiring was changed from bus-bar to ground

plane.

Rev. B: An LPF (low-pass filter) was added to the output buffer. Since this change

does not require any modification to the PCB, the PCB (PCB4) remains as

Rev.A.

U7(PGA2310):P7(SDO) is connected to PL401:P6, but this is a mistake due to a misunderstanding. SDO (Serial Data Output) pin is meant to be connected to the SDI (Serial Data Input) of another PGA2310 when using multiple PGA2310s. Connecting it to MCU is no use, so MCU (to be more precise, firmware of MCU) simply ignores this signal.

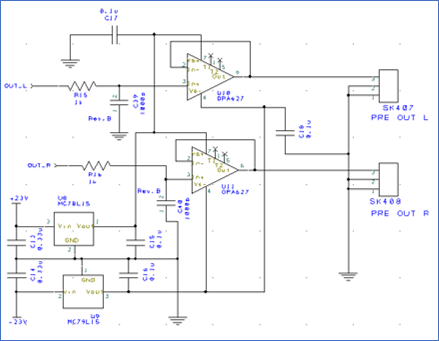

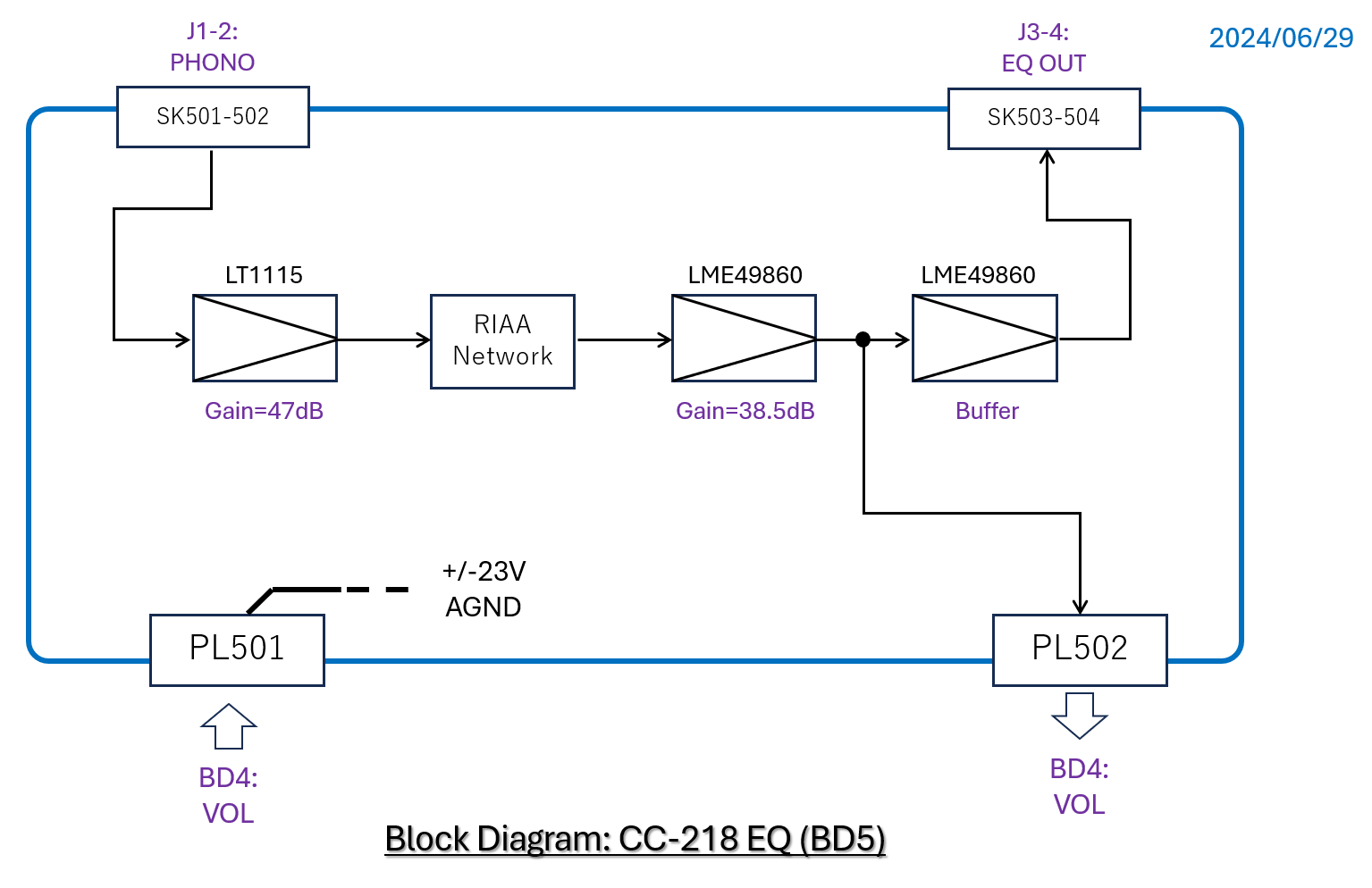

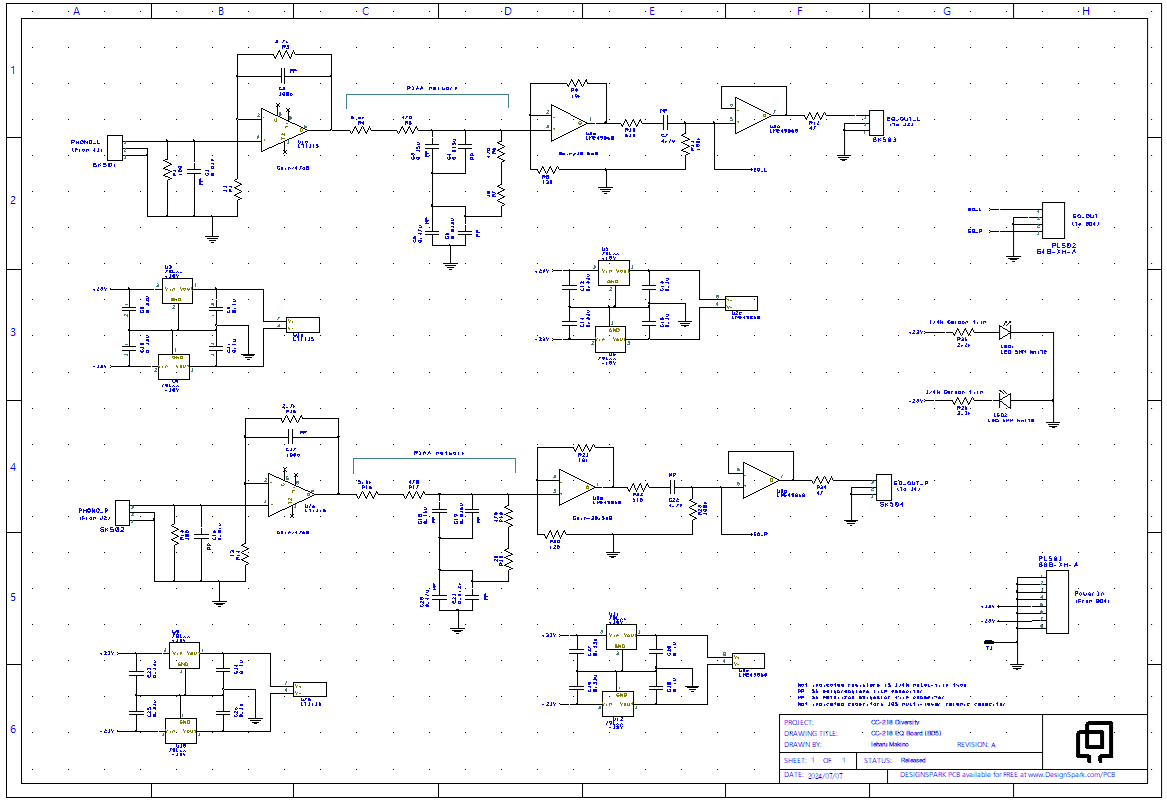

BD5: CC-218 EQ

Phono equalizer board designed specifically for MC-type cartridges.

It combines an ultra-low-noise op amp, LT1115, with passive filters. The

gain is set slightly higher than the industry standard, at 66dB (@1kHz).

<CC-218 EQ Specifications: CC-218_EQ_Spec.pdf>

This circuit is not my original design; it is based on an application example featured in the LT1115 datasheet. The only difference is that the gain of the second stage has been increased by 10dB. While the application example naturally uses only LT op amps, I used TI's LME49860 for all stages except the first.

The output is not only sent to BD4 (CC-218 VOL), but also routed to the RCA jacks (EQ OUT (J3, J4)) on Back Panel via the buffer (voltage follower). So, CC-218 can be used as a standalone phono equalizer, too.

The resistors used in the RIAA network have a tolerance of 1%, and the

capacitors have a tolerance of 5%. Since the resistor and capacitor values

are selected from the E24 and E12 series, respectively, they deviate from

the calculated ideal values. To get as close as possible to the calculated

values, two resistors were connected in series and two capacitors in parallel.

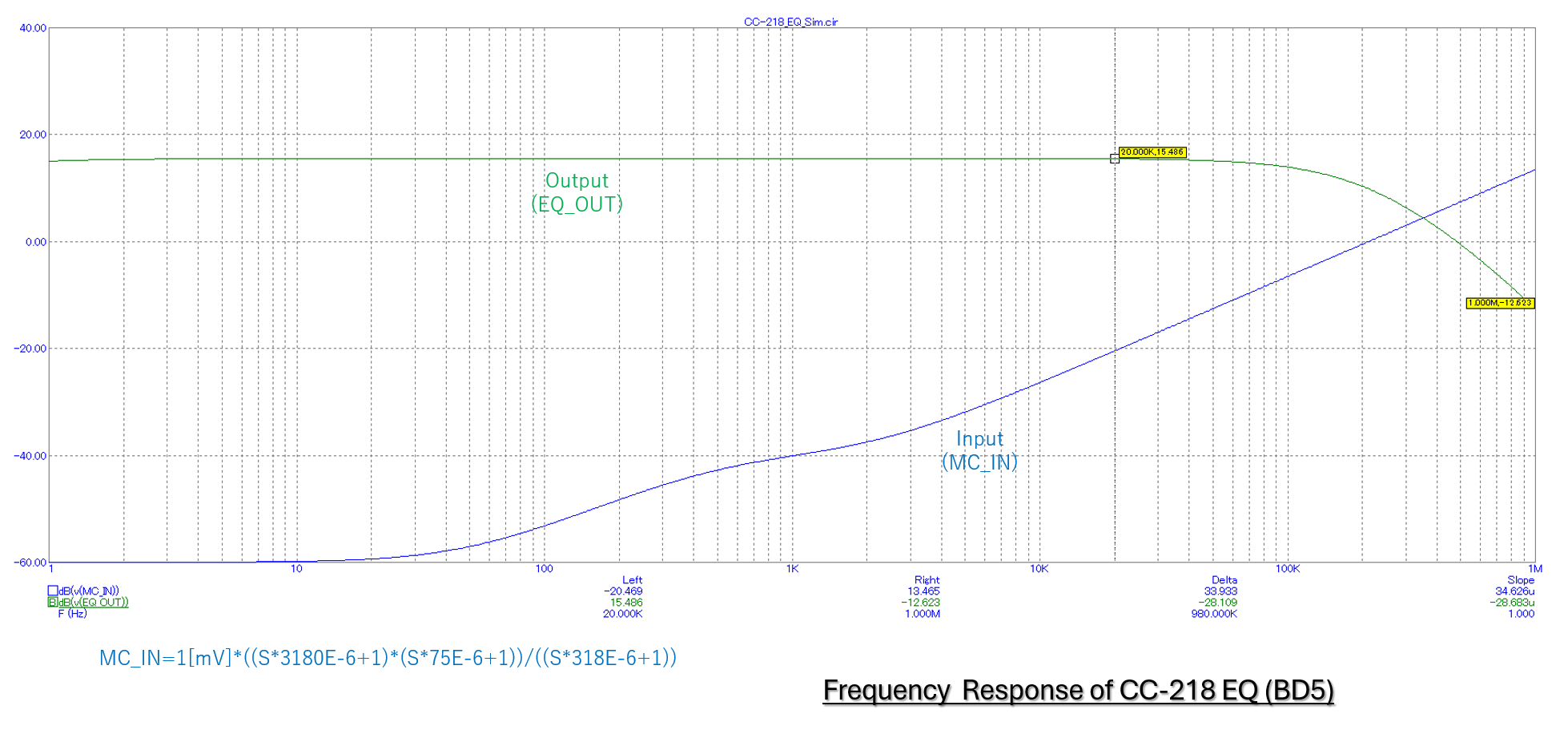

Even so, there were still slight discrepancies, so I verified the characteristics

through simulation.

In the simulation result shown below, the input signal has RIAA-compliant

pre-emphasis applied. If the output appears flat, it indicates that the

characteristics are correct.

The RIAA deviation came out to be –0.045dB to +0.023 dB (20Hz ~ 20kHz), which is an excellent result.

For the op amps, I selected audio-grade components, but for the passive

components, I also used non-audio-grade parts.

The resistors are basically audio-grade metal film resistors (REY series)

by Takman. However, since this series has been discontinued, some resistance

values were difficult to obtain. As substitutes, I used KOA’s general-purpose

metal film resistors (MF1/4C). There’s not much difference in specifications

between the two, but Takman uses OFC leads.

For the capacitors used in the RIAA network, I selected polypropylene capacitors

(UPZ series) from Nichicon. However, for larger capacitance values (0.47 µF

and 4.7 µF), I used metallized polyester capacitors (ECQE series) by Panasonic.

There’s no particular reason for this choice—it simply met the requirements

of being a film capacitor with 5% tolerance, rated at 50V or more, and

readily available at the time.

Using Vishay’s audio-grade resistors or WIMA’s audio-grade capacitors might have appealed more to audio enthusiasts, but lately, I’ve stopped being particular about using audio-specific components.

Rev.A:

Although the ECQE capacitors with a 100 V rating would have been sufficient,

they seemed to take quite a while to source, so I opted for the 250 V version

instead. However, their physical size is considerably larger, making it

difficult to mount them on the already-ordered PCB (PCB5). As a result,

I modified the PCB to accommodate the 250 V parts. It may sound odd to

say that modifying the PCB is easier than changing the capacitors, but

that’s honestly how it felt. The PCB cost about 3,200 JPY including shipping,

which isn’t much different from buying 10 audio-grade capacitors. Even

from an economic standpoint, I didn’t feel burdened by the revision.

<Circuit design document: CC-218_EQ_CircuitDesign.pdf>

PCB Design

PCB1: CC-218 DISP

I assumed it would be easy to design the PCB, since it’s a simple board

with just one IC, three 7-seg LEDs, and three connectors—but that was a

big mistake. It ended up taking five whole months. Even though it was my

first time designing a PCB, I never expected it to be this much trouble.

The AS1115 in a QSOP-24 package has a pin pitch of only 0.4mm, and with

such dense traces around it, it’s difficult not only to add through-holes

but even to place vias. In addition to that, most of the space on the bottom

side was taken up by the 7-seg LEDs, making it hard to place decoupling

capacitors near the AS1115.

At first, I planned to use the auto-routing function of the CAD software

(DesignSpark PCB), and if there were any nets that didn’t get connected,

I would manually route just those remaining nets myself. However, this

approach didn’t work.

In reality, there were nets that the auto-router couldn’t connect. And

if even a computer couldn’t figure it out, there was no way I could. Trying

to route a single trace meant I had to move another one, which then required

moving yet another trace to make space—and in the end, I had to start over

from scratch.

In the end, I couldn’t fit all the traces no matter what I did, so I ended up changing the board dimensions. I extended the height by 8 mm.

|

| The height has been changed from 32mm to 40mm |

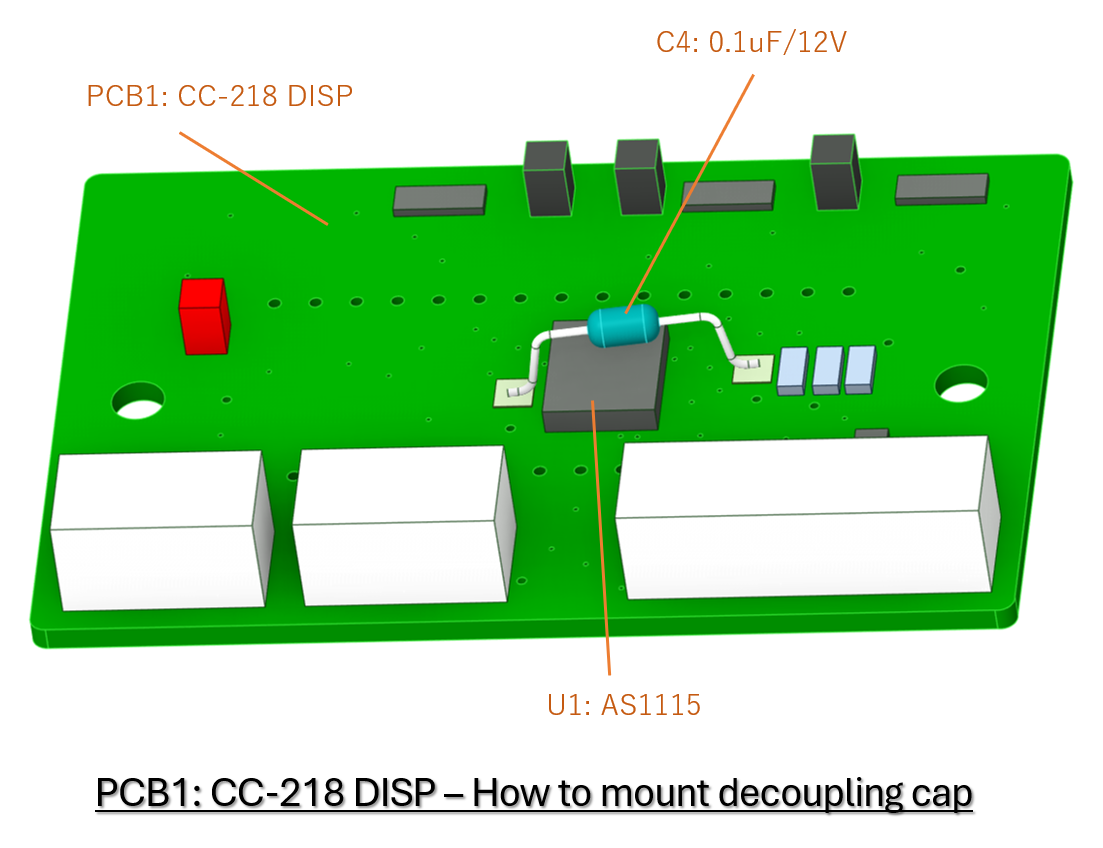

To place the decoupling capacitor for the power rail near the AS1115, I used a little trick: I mounted the capacitor so that it straddles over the top of the AS1115.

|

| Mount the capacitor (C4) so that it straddles over AS1115. Place pads of +5V and GND near AS1115. The cap is soldered to the pads. |

For further details of designing this PCB, see the document below:

<PCB design document: CC-218_DISP_PCB.pdf>

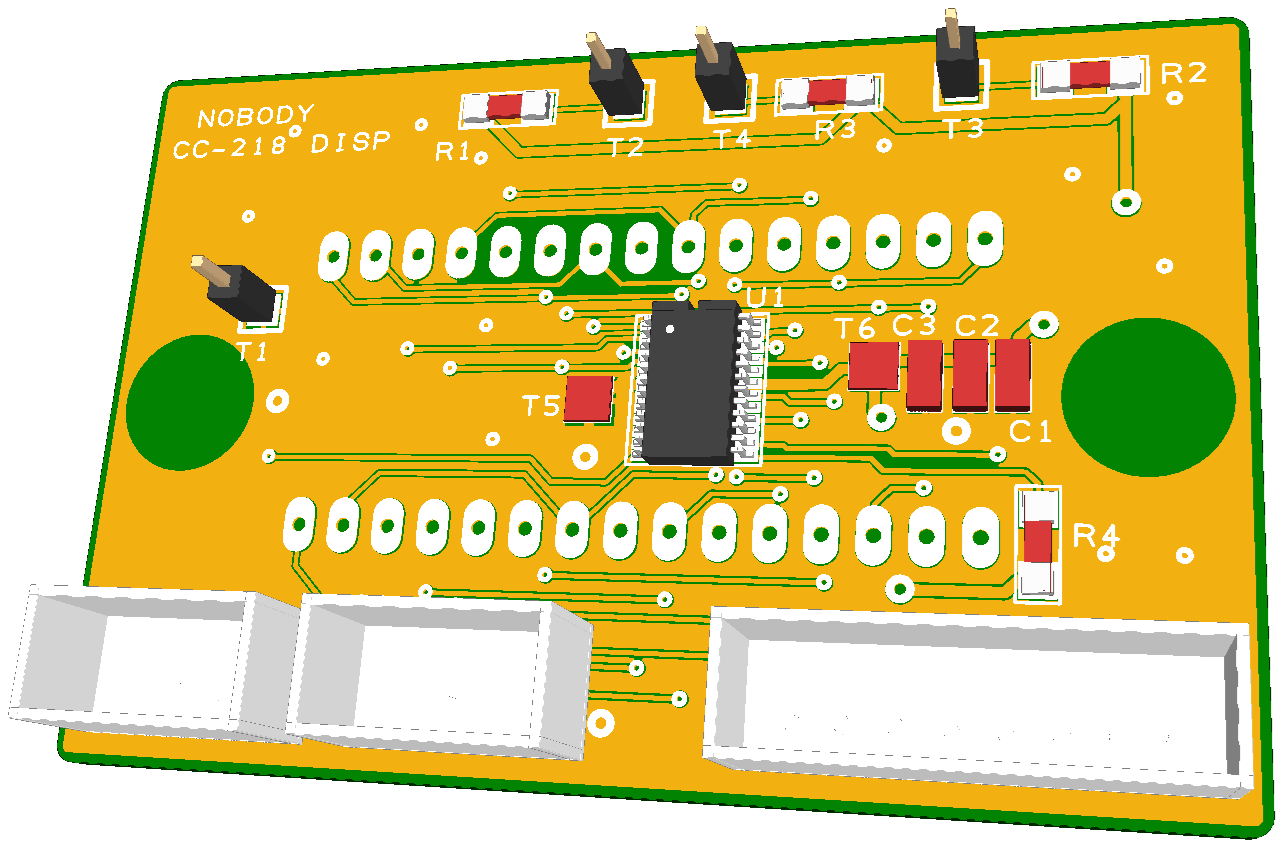

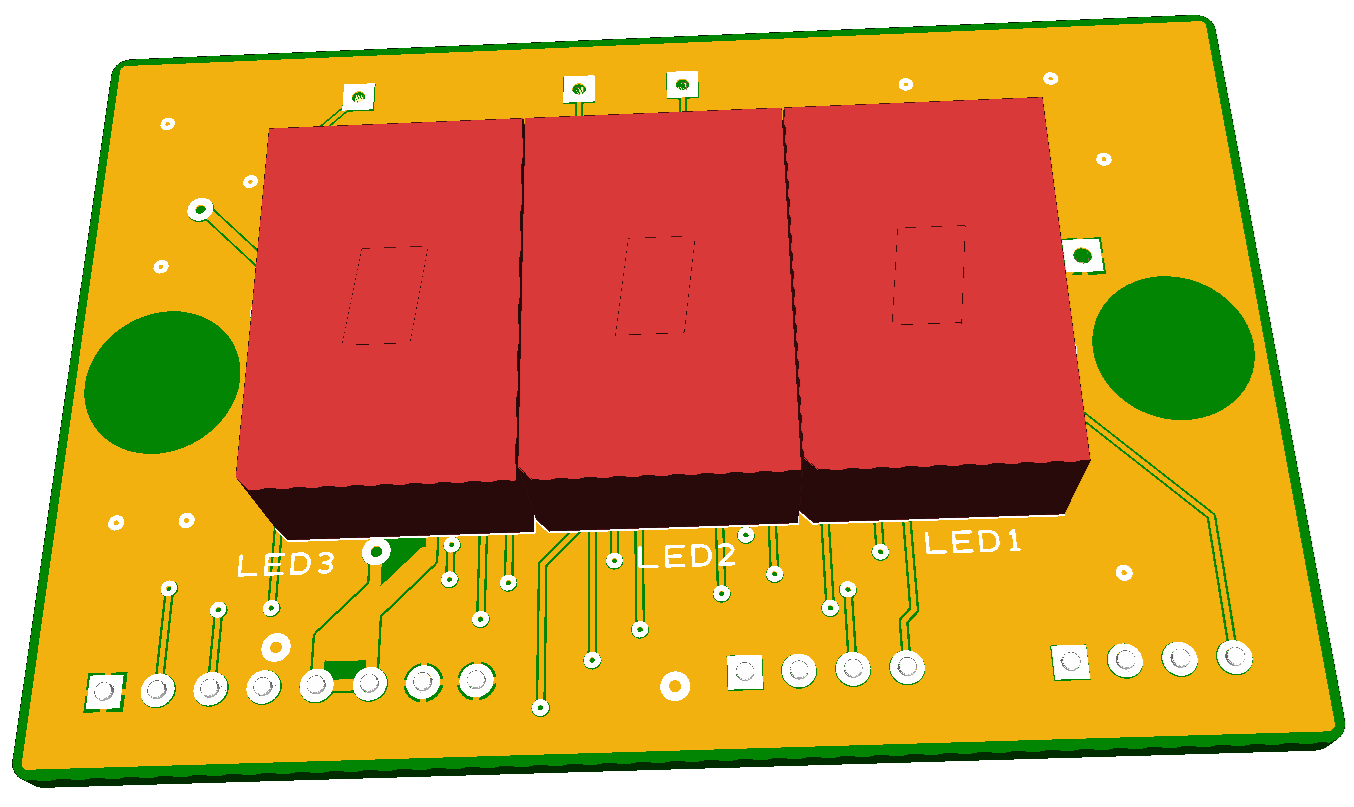

The images below are renderings of the completed board generated by the PCB CAD software.

|

|

| Rendering created by PCB CAD - CC-218 DISP (top) | Rendering created by PCB CAD - CC-218 DISP (bottom) |

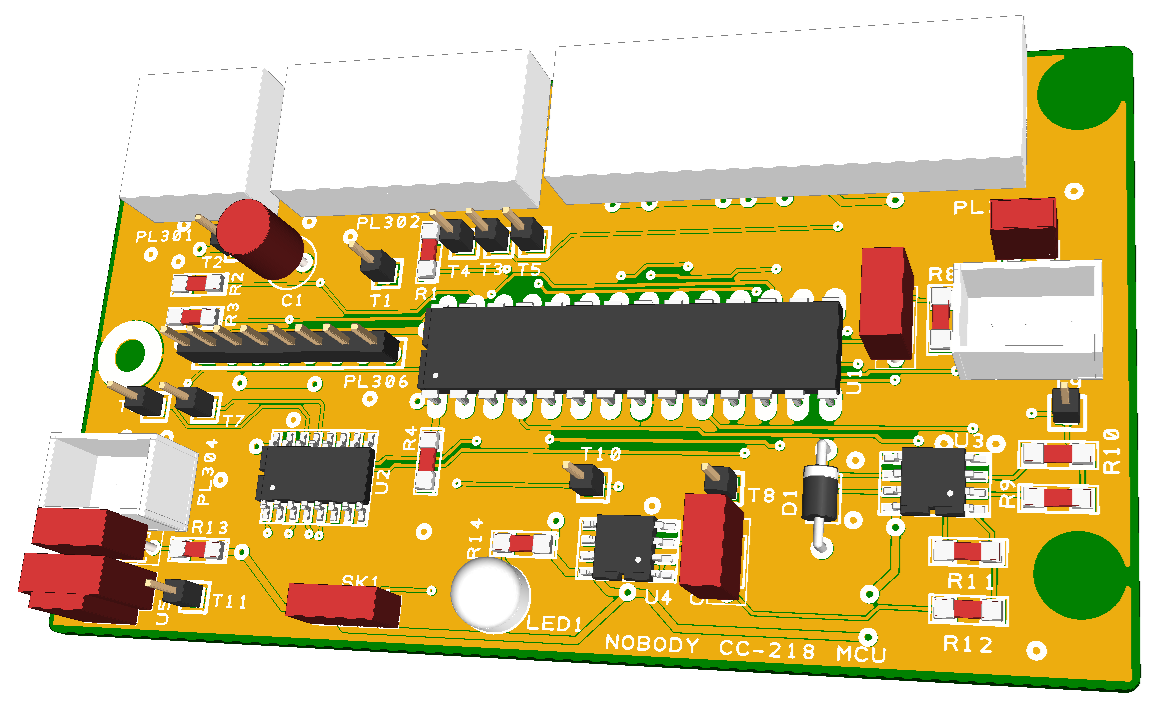

PCB3: CC-218 MCU

Compared to PCB1, this board has many more components, yet its area is

only slightly larger. So, I expected it to be even more challenging than

PCB1, but surprisingly, the design progressed smoothly. I completed the

design in about five weeks. I was becoming more proficient in PCB design.

<PCB design document: CC-218_MCU_PCB.pdf>

|

|

| Rendering created by PCB CAD - CC-218 MCU (top) | Rendering created by PCB CAD - CC-218 MCU (bottom) |

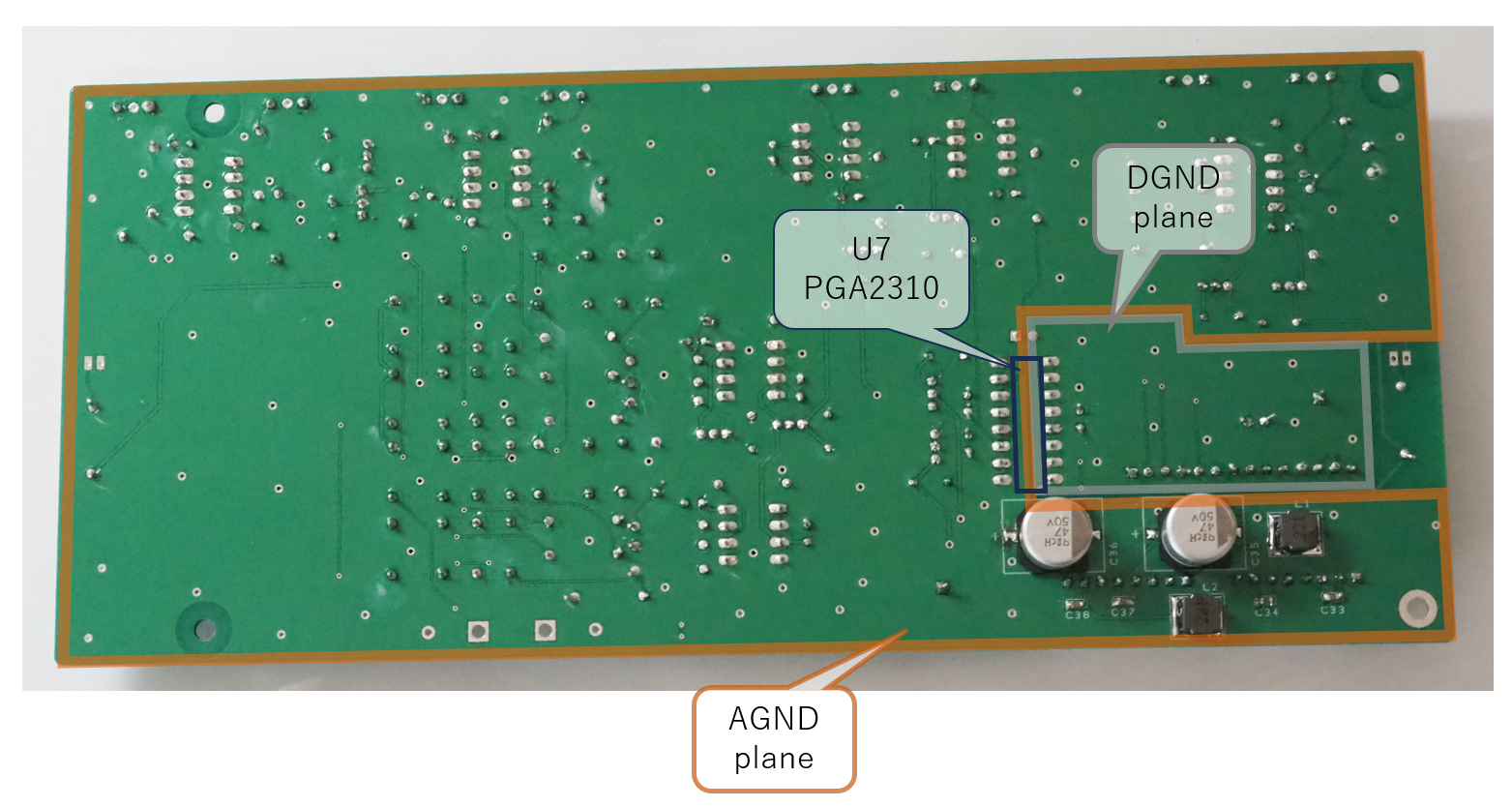

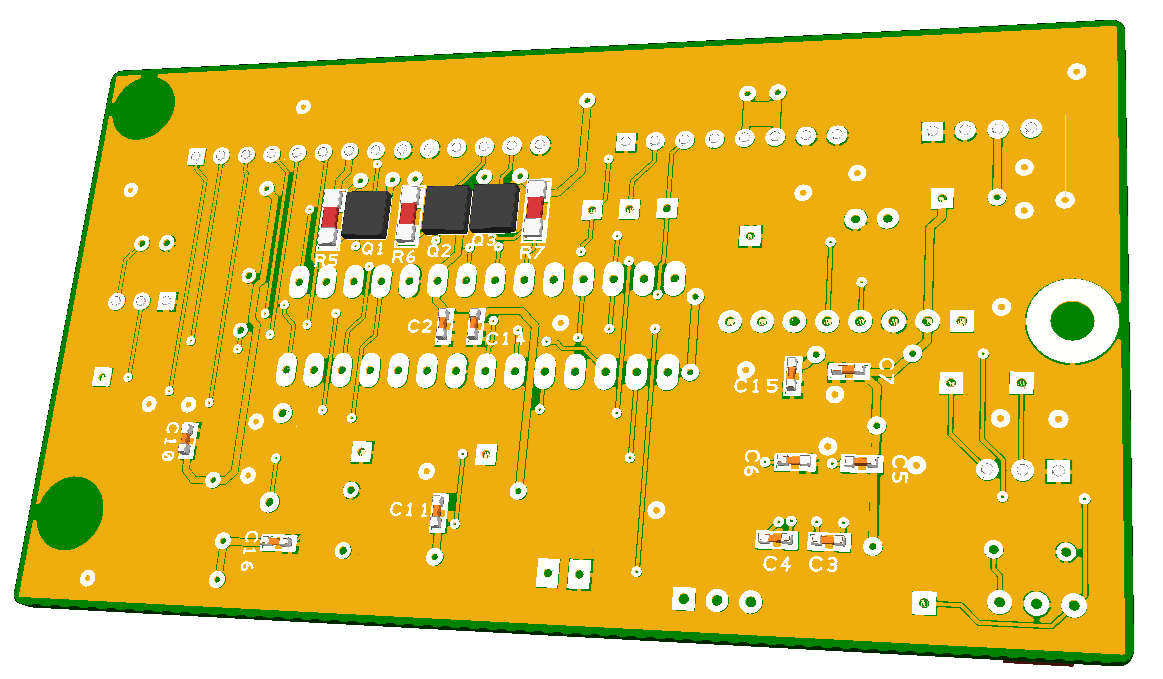

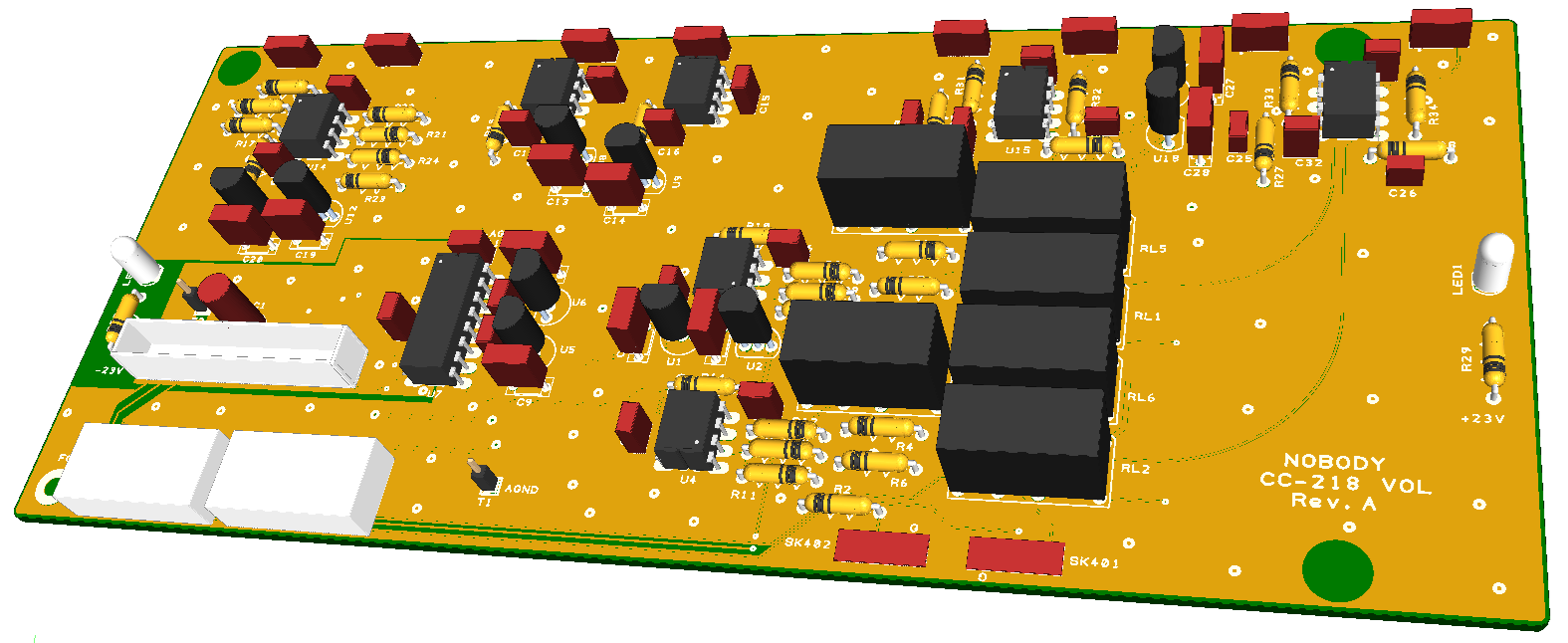

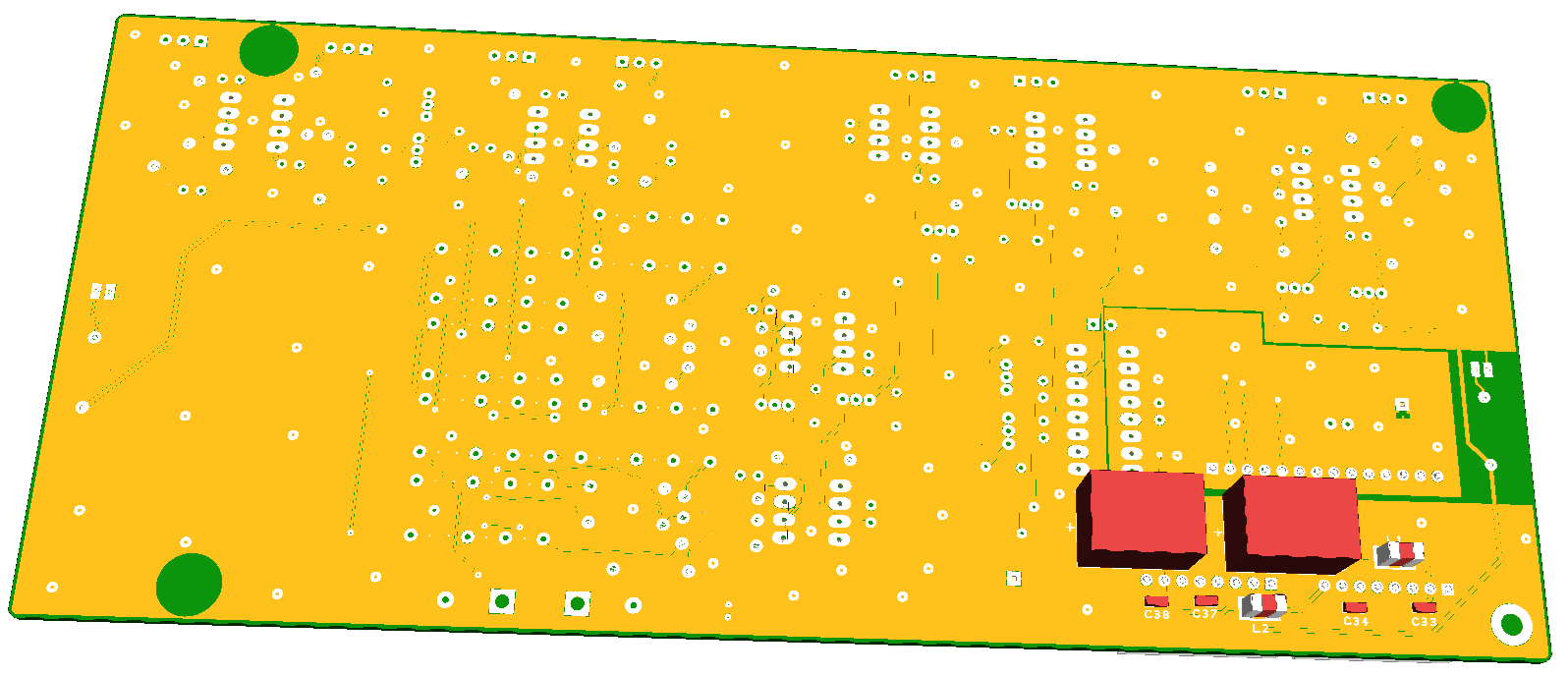

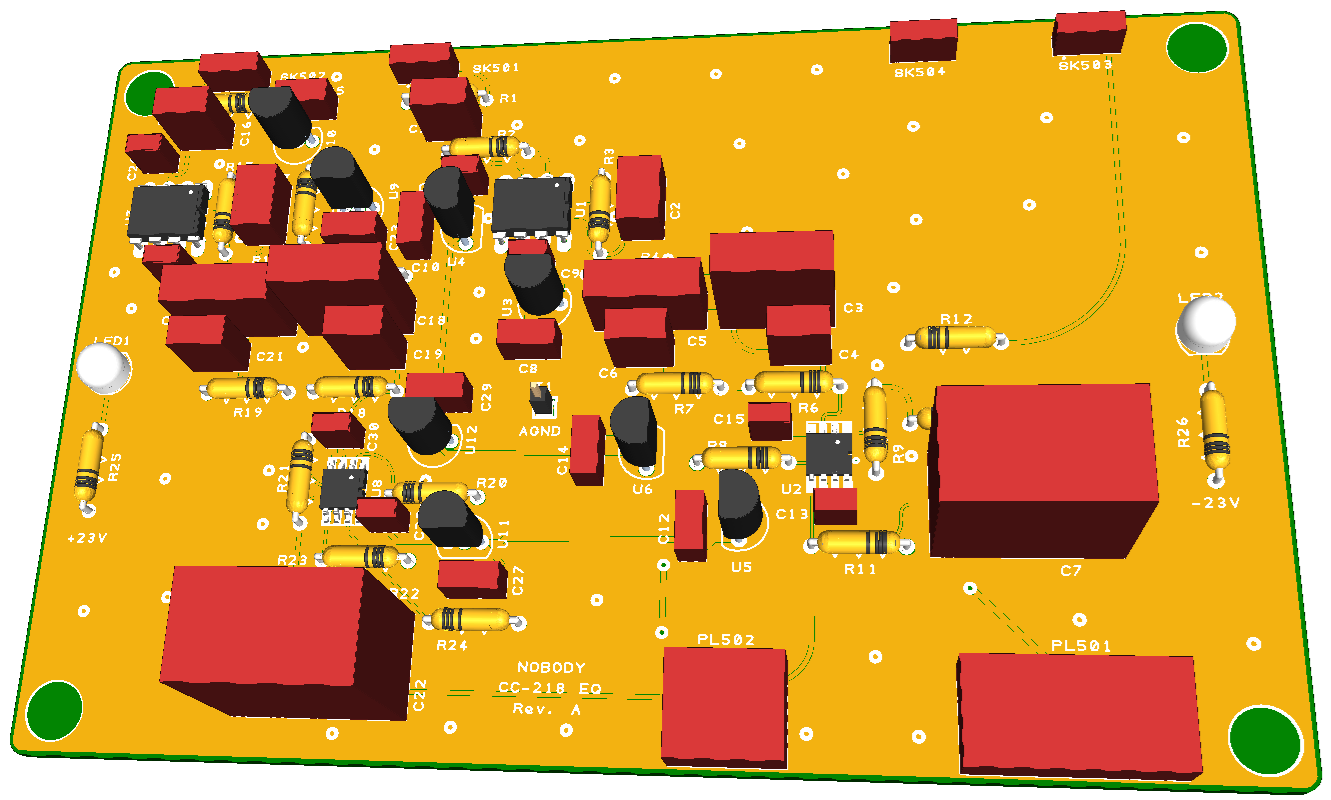

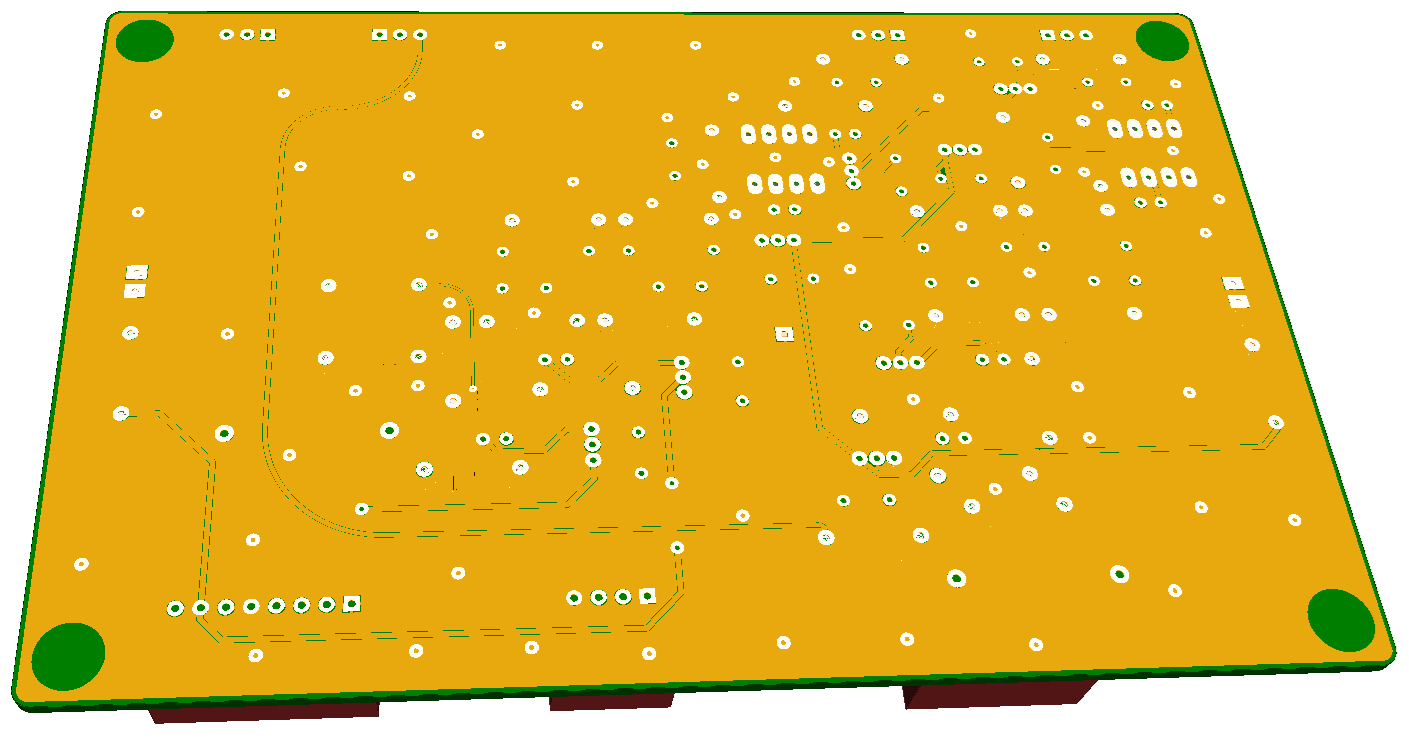

PCB4: CC-218 VOL

This is my first time designing a PCB that includes analog circuits. I considered changing the design rules, but in the end, decided to keep most of them unchanged. The main modification was making the trace widths for analog signals and analog ground (AGND) wider than those for digital circuits. Specifically, the analog signal traces are 0.2mm wide (compared to 0.152mm for digital signals), and the AGND is 1.8mm wide (compared to 0.5mm or 1.2mm for DGND).

I carefully designed the routing of AGND, but the 1.8mm trace width doesn’t provide sufficiently low impedance. Therefore, I decided to reinforce it with 1mm tin-plated copper wires.

|

| AGND is placed on the bottom side, with portions of the solder mask removed

along its track. The tin-plated wire is soldered onto the exposed areas

of the track. This design was rejected later! |

A guard ring should be placed around the input pins of op amps. To implement this, I used the available space on the top layer as guard ground (GGND) plane, which prevents crosstalks between signals. GGND is connected to AGND at a single point.

I decided not to employ this AGND and GGND design when revising this PCB to Rev.A. Although the purpose of Rev.A was not related to AGND, I deleted GGND plane, and poured copper in the availabe spaces on both sides and designated them as AGND planes, because using AGND planes on BD5 (Phono EQ board) had yielded good results.

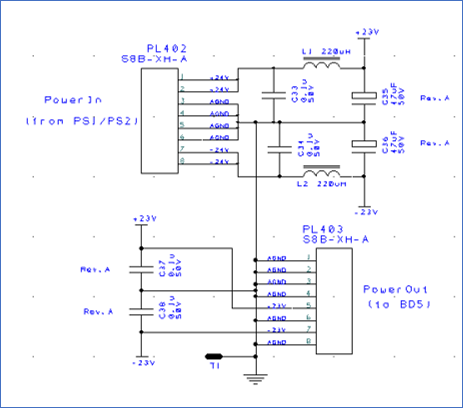

Rev.A

A noise filter was added to the ±24V DC power rails. All the components

of the filter are SMDs (surface-mount device) and are mounted on the bottom

side near connectors PL402 and PL403.

AGND tracks were also changed to the AGND planes.

<PCB design document: CC-218_VOL_PCB.pdf>

|

|

| Rendering created by PCB CAD - CC-218 VOL (top) | Rendering created by PCB CAD - CC-218 VOL (bottom) |

PCB5: CC-218 EQ

Since this is a high-sensitivity amplifier with an input sensitivity of

0.3mV, even the best circuit design will result in a bad sound quality

with noise and distortion if the PCB design is poor. I felt quite a bit

of pressure during the PCB design process. What I struggled with most was

the GND routing. At one point, I even considered switching to a poured

GND plane. In an amplifier that handles extremely small signals, even a

1 μV fluctuation in GND potential can cause audible noise. An ultra-low-noise

amplifier needs GND that is as stable and immovable as the Earth itself.

However, one thing kept nagging at me—a lesson I learned from senior engineers

long ago: Never use GND plane in low-frequency amplifier circuits. The

reasons include: (1) Currents from multiple amplification stages can overlap

within the GND plane. (2) Stray currents can flow through GND. (3) Eddy

currents can develop within GND plane. (4) Increased stray capacitance

between the signal and GND tracks can cause phase shifts and attenuation

at high frequencies.

The issue in point (1) is that the impedance within the GND plane becomes a common impedance, leading to crosstalk between circuits. However, the impedance of the GND plane is sufficiently low, and the level of crosstalk can be considered completely negligible. Points (2) and (3) are thought to potentially cause signal waveform distortion, but it’s unlikely that distortion of any significant magnitude would actually occur. Point (4) can be completely dismissed. If stray capacitance were to cause phase shifts within the audible frequency range, then GND planes could not be used in digital boards. In reality, however, GND planes are a standard technique used in nearly all digital PCBs. That said, if the output impedance of an amplification stage is high, the effects of stray capacitance might become noticeable.

<PCB design document: CC-218_EQ_PCB.pdf>

|

|

| Rendering created by PCB CAD - CC-218 EQ (top) | Rendering created by PCB CAD - CC-218 EQ (bottom) |

BOMs and Assembly Manuals

BOM (Total)

<BOM: CC-218_BOM.pdf>

BOMs of the boards

<BOM of Display Board: CC-218_DISP_BOM.pdf>

<BOM of Indicator Board: CC-218_IND_BOM.pdf>

<BOM of Controller Board: CC-218_MCU_BOM.pdf>

<BOM of Volume Board: CC-218_VOL_BOM.pdf>

<BOM of Phono EQ: CC-218_EQ_BOM.pdf>

Assembly manual (Total)

<Assy manual: CC-218_Assy.pdf>

Assembly manuals for the boards

<Assy manual for Display Board: CC-218_DISP_Assy.pdf>

<Assy manual for Indicator Board: CC-218_IND_Assy.pdf>

<Assy manual for Controller Board: CC-218_MCU_Assy.pdf>

<Assy manual for Volume Board: CC-218_VOL_Assy.pdf>

<Assy manual for PhonoEQ Board: CC-218_EQ_Assy.pdf>

|

|

| Rendering of Display Module |

Rendering of Indicator Module |

|

|

| Rendering of VR Module | Rendering of Rotary SW Module |

Firmware Design

This firmware (F/W) is named 'CC-218 FW'.

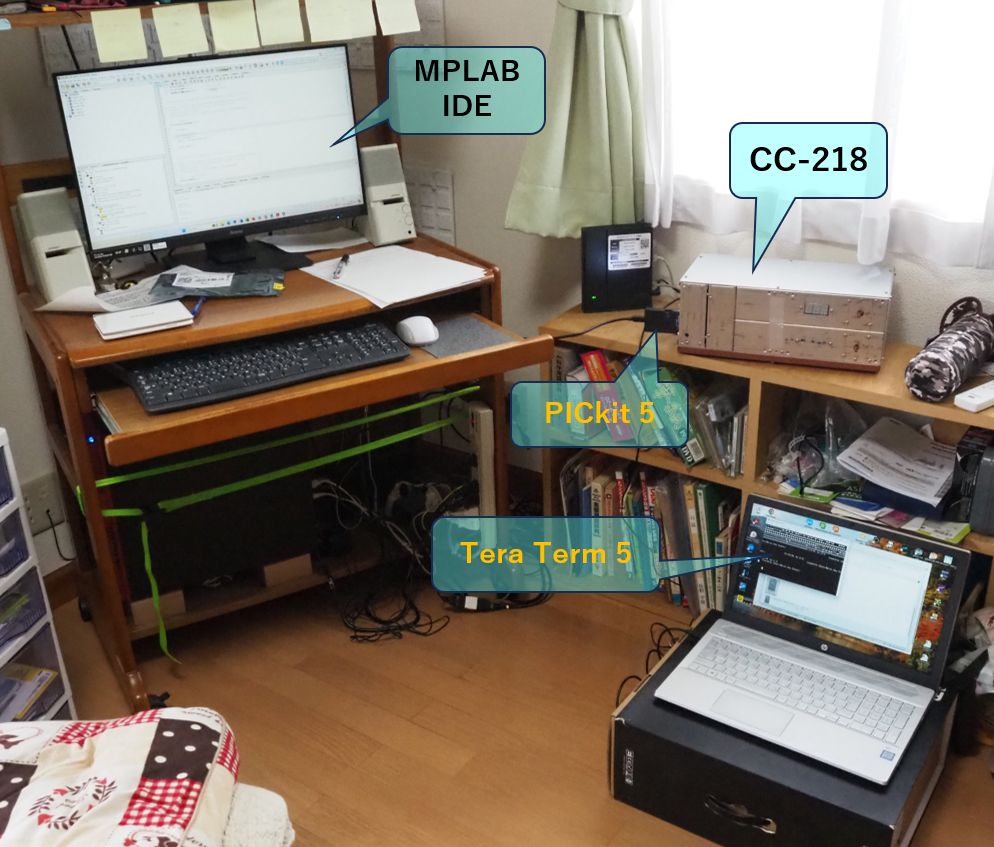

Development environment and programming language

I use IDE (Integrated Develop Environment),which is the free software offerred by Microchip.

Development environment: MPLAB X IDE v6.20

Compiler:XC8 v2.50 (language C)

Debugger/programmer:MPLAB PICkit 5 (ICD: In-Circuit Debugger/programmer)

I write the entire source code in C. To avoid the need for using assembly language, XC8 provides directives (such as #pragma config) and macros (such as CLRWDT()) for handling operations that cannot be written in standard C.

I purchased the PICkit 5 from Digi-Key for 16,378 JPY. It was cheaper than

buying it from the Microchip Store.

The in-circuit method refers to running the firmware using the MCU chip

on the target system. For this, the firmware needs to be built specifically

for debugging. When built as a debug version, the firmware has debug-related

code linked in, which slightly increases memory usage and may slow down

execution speed.

Using an ICE (In-Circuit Emulator) allows real-time execution without modifying

the firmware, but it's quite expensive (around 200,000 JPY ?).

Note that the term “programmer” here does not refer to a person who writes

code, but rather to a device that writes programs or data into the flash

memory of a microcontroller chip.

As will be explained in the section on “Debugging Method,” in-circuit debuggers are only suitable for very simple firmware that

doesn’t use interrupts. The main purpose of the PICkit 5 is programming

rather than debugging.

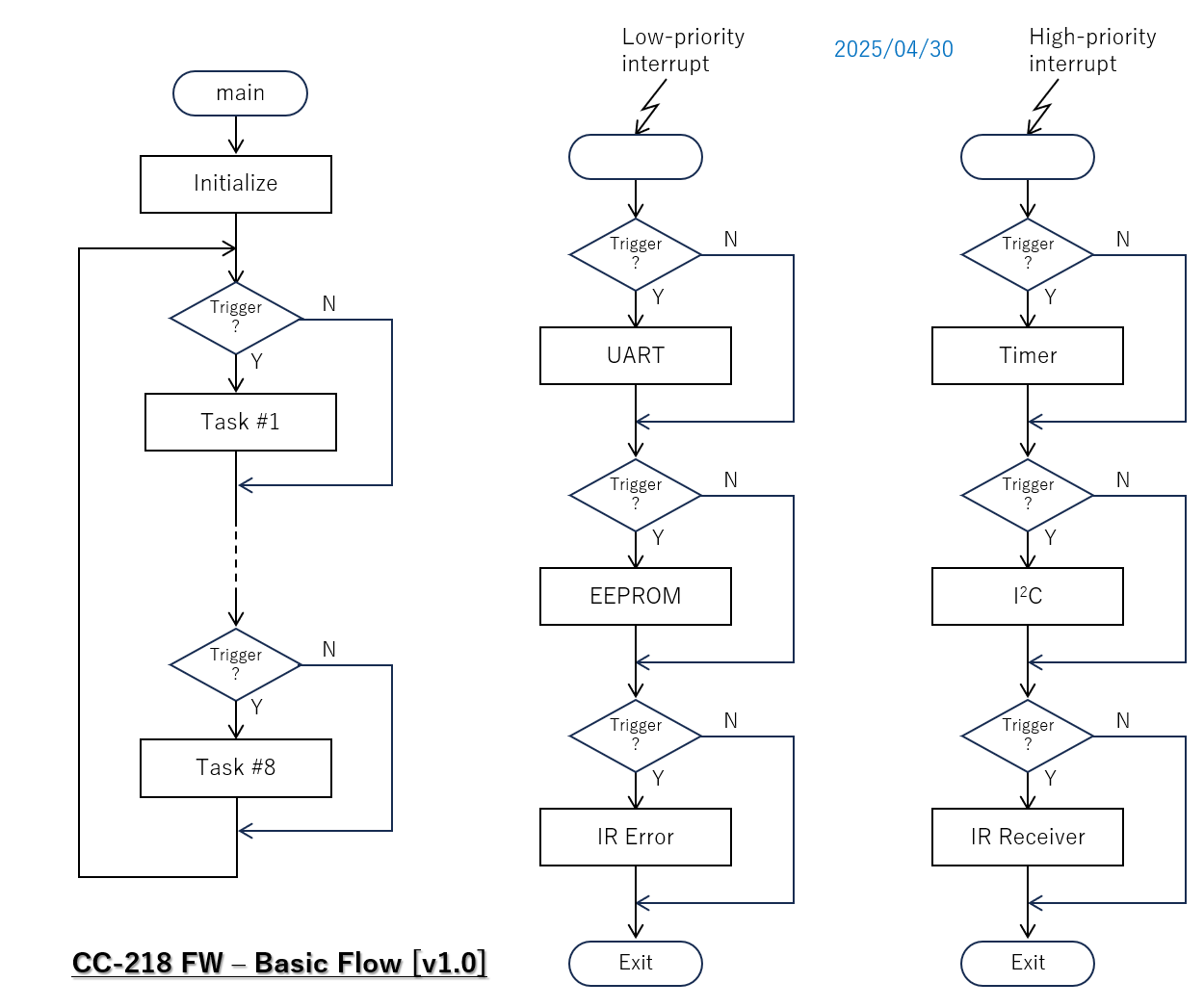

Basic structure

Generally, firmware for an amplifier is relatively simple and does not

require high real-time performance, so I adopted a simple structure without

using an RTOS (Real-Time Operating System). This is what’s called a stand-alone

approach.

Unlike regular software, firmware does not terminate. It continues running

as long as the target system is powered on. As shown in the left part of

the flowchart below, after completing initialization, it enters the infinite

loop. Within this loop, each task is executed.

Formally, this program structure is single-task, but with a bit of ingenuity,

it can behave like a multitasking system.

Each task has to be designed so that it does not wait for events. Events

refer to things like changes in input port states or interrupt requests

from peripherals. If a task waits for an event within itself, it ends up

occupying the CPU for too long, which delays the execution of other tasks.

Before executing each task, the program checks whether the conditions for

running that task are met. If not, it moves on to the next task. As long

as one iteration of the infinite loop completes in at most a few tens of

milliseconds, the system can appear to operate like a multitasking one.

This approach is sometimes referred to as “pseudo-multitasking.”

Tasks

CC-218 FW includes eight tasks.

| Task # | Task name | Trigger | Action |

|---|---|---|---|

| 1 | Execute Console Command | Receive command from Console | Analyze and execute command |

| 2 | Execute Remote Command | Receive command from Remote | Analyze and execute command |

| 3 | Execute Test Program | When F/W is in Diag Mode (*1) | Execute test program (*2) Exit Diag Mode if test is over |

| 4 | Execute Test Program at Tick | Diag Tick (*3) is generated in Diag Mode | Execute test program Exit Diag Mode if test is over |

| 5 | Gain Control | Main Tick (*4) is generated after VR1 (*5) is operated |

Calculate target gain from the angle of VR1 Set the target gain to eVolume chip Display the gain |

| 6 | Selector Control | Main Tick is generated after SW2 (*6) is operated | Read SW2 and recognize which source to be selected Drive Selector Relays Indicate the selected source |

| 7 | Muting | Main Tick is generated during Muting Mode | Decrease or increase the gain Display the gain |

| 8 | Display Timeout | 3 seconds elapsed since the last change of Display | Turn off Display in certain Display Modes |

*1: Diagnostics Mode is one of four modes (the others are Stand-alone Mode,

Master Mode and Balance Adjust Mode) of CC-218 FW, where test programs

are executed. The only way to enter Diagnostics Mode is receiving test

program commands from Console.

*2: Test programs are used to check hardware and/or firmware. Only some Console

commands invoke them. The test programs are, so to speak, "easter

egg" (hidden feature).

*3: Diag Tick is a timing signal for the test programs. It is generated at

1sec intervals.

*4: Main Tick is a timing signal for the main routine (main()). It is generated

at 0.1sec intervals.

*5: VR1 is the variable resistor rotated by Volume Knob.

*6: SW2 is the rotary switch rotated by Selector Knob.

Interrupts

When a response must be made in a very short time after an event occurs,

interrupts are used.

PIC18F2520 has two levels of interrupt priority. High-priority interrupts

are used for processing that requires more urgency, while other events

are handled by low-priority interrupts.

Note that PIC18F2520 does not support NMI (non-maskable interrupt).

Low-priority interrupts

| ISR (*1) | Source | Event | Action |

|---|---|---|---|

| UART(*2) Transmit |

UART (EUSART(*3)) |

Tx Register is empty (Transmit is ready) | Transfer one byte of data from FIFO(*4) to Tx Register, if FIFO is not empty |

| UART Receive |

UART (EUSART) |

Rx Register is full (Receive is ready) | Transfer one byte of data from Rx Register to FIFO |

| EEPROM(*5) | EEPROM | Write is done | Check if error occurred or not |

| IR Error | Timer1 (*6) | Overflow of Timer1, which means disruption of IR signal | Reset the state machine (*7) of IR Remote Driver (*8) |

*1: Interrupt Service Routine

*2: Universal Asynchronous Receiver/Transmitter -- Peripheral device that

executes asynchronous serial communication (a part of EUSART)

*3: Enhanced Universal Synchronous/Asynchronous Receiver/Transmitter -- Peripheral

device that executes serial communication (built-in device of MCU chip)

*4: First-In First-Out buffer -- Data buffer memory in UART Driver

*5: Electronically Erasable and Programmable Read-Only Memory (nonvolatile

memory, built-in device of MCU chip)

*6: Timer/counter (built-in device of MCU chip)

*7: State machine -- Explain later

*8: Device driver that processes signals received from IR remote

High-priority interrupts

| ISR | Source | Event | Action |

|---|---|---|---|

| Timer | Timer0 (*1) | Overflow of Timer0 (at 1msec intervals) | Count down Soft Timer (*2) by 1 |

| I2C | MSSP (*3) | End of transmit/receive | Trigger the state machine (*4) of I2C Driver |

| IR Receiver | PORTB (*5) | Transition of the output of IR Receiver (nIR_IN) | Trigger the state machine of IR Remote Driver |

*1: Timer/counter (built-in device of MCU chip)

*2: Count-down timer in F/W decreased by F/W

*3: Master Synchronous Serial Port -- Built-in serial port of MCU chip. Unlike

EUSART, which commnucates with an external system such as PC, MSSP communicates

with internal devices. It supports SPI mode and I2C mode. The latter is

selected in CC-218 FW.

*4: State machine -- Explain later

*5: I/O port of MCU chip. PORTB receives the signal nIR_IN from IR Receiver

Modules

Now we have definitions of the tasks and ISRs.

It is difficult to include all these tasks and ISRs in a single source

file. So, I divided F/W into modules as shown in the table below.

The expression [vn.nn] indicates the final version numbers of each module.

| Module | Source file | Header file | Description |

|---|---|---|---|

| MAIN | main.c | main.h | The main module including main() |

| INIT | init.c [v0.50] | init.h [v0.52] | Initialize system |

| DIAG | diag.c [v0.31] | diag.h [v0.30] | Self-check programs |

| CNSL | cnsl.c [v0.12] | cnsl.h [v0.11] | Console service routines (UART Driver) |

| INTR | intr.c [v0.05] | --- | Interrupt service routines including I2C Driver |

| DISP | disp.c [v0.23] | disp.h [v0.23] | Display Driver |

| VOLM | volm.c [v0.30] | volm.h [v0.30] | Read VR1, calculate gain data and display the gain |

| REMT | remt.c [v0.10] | remt.h [v0.10] | IR Remote Driver |

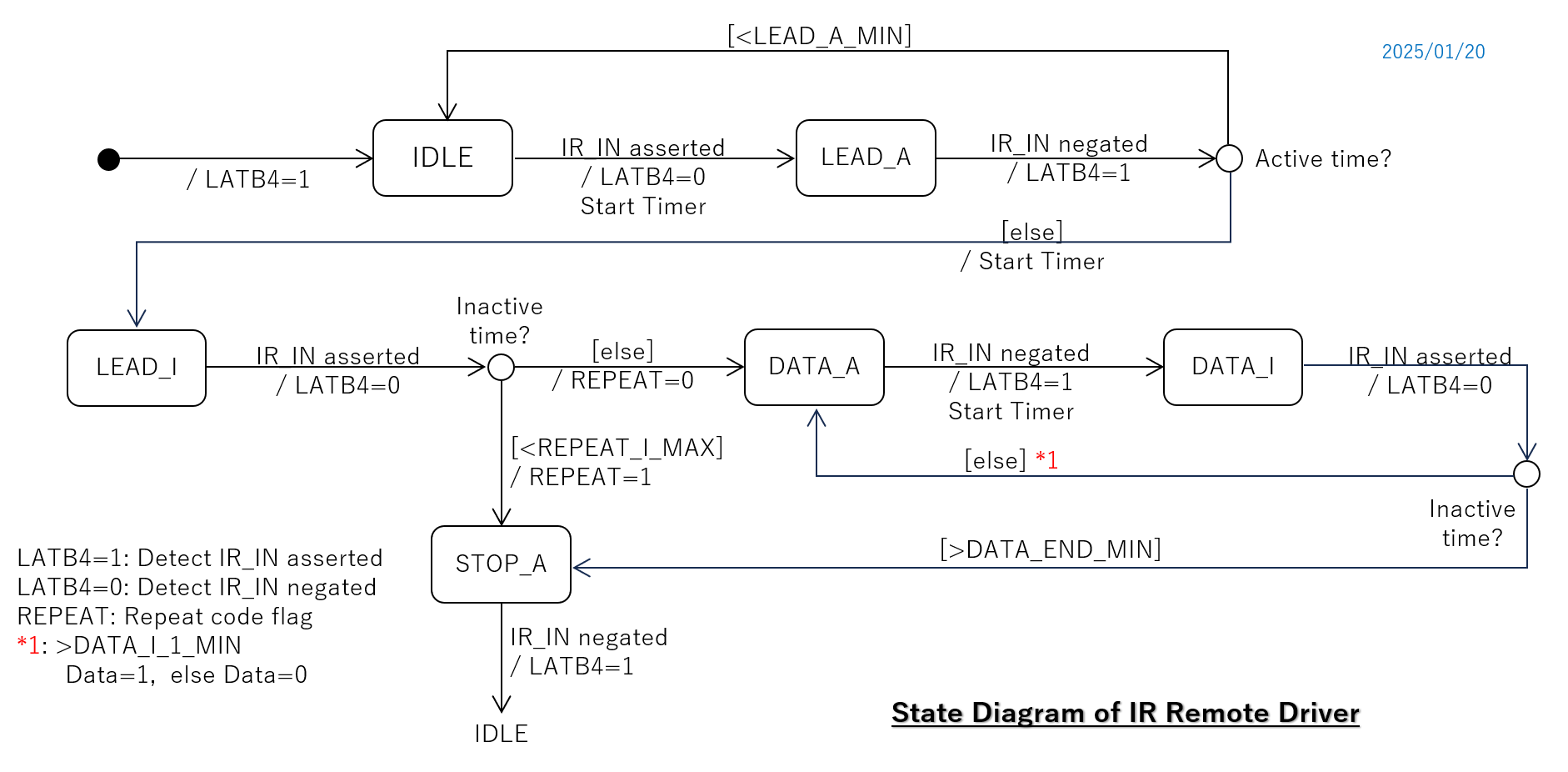

State machines

Since firmware is based on event-driven programming, the execution order—aside

from the overall flow—cannot be represented using a flowchart. Instead,

it is helpful to define state machines and use state transition diagrams

to describe the behavior.

CC-218 FW uses three state machines. Only the state transition diagrams

are shown here; for details, please refer to the design documentation.

<F/W design document: CC-218_FW_Design.pdf>

|

| State transition diagram -- I2C Driver |

|

| State transition diagram -- Display Driver |

|

| State transition diagram -- IR Remote Driver |

Design procedure

Firmware tends to be more complex in terms of function and structure than

hardware, so using a design-then-implement approach can lead to confusion.

This is especially true for a project like the CC-218, where both the hardware

and firmware are newly developed—it's hard to know where bugs might be

hiding. Therefore, it's best to follow a step-by-step approach, where design,

implementation, and debugging are carried out in parallel.

First, design and implement firmware with only the minimum required functionality.

Then write it to the target chip, run it, and debug. Once that works, add

one more function to the firmware and debug again in the same way. Repeat

this process until the firmware is complete.

Each step is assigned its own version number.

| Version | Feature | Purpose |

|---|---|---|

| v0.0 | Make the LED connected to PORTC of MCU chip blink with a 2sec cycle | Confirm basic operations of IDE, PICKit (ICD) and MCU chip |

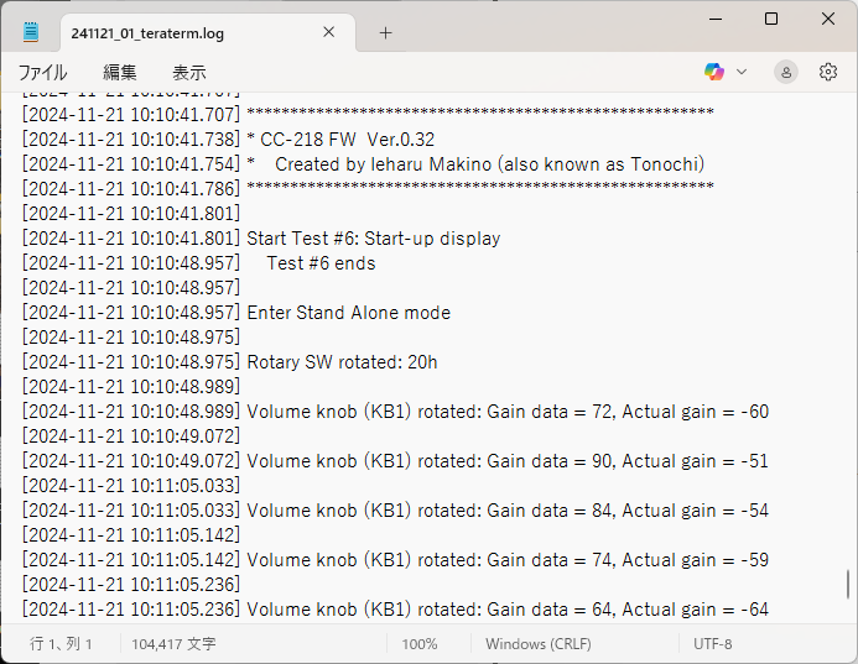

| v0.1 | Connect MCU to Console (Tera Term) by using newly added UART Driver (CNSL Module) | Display the internal status and events of MCU on Console screen |

| v0.2 | Display numeric characters on Display by using the display controller (AS1115)

and newly added I2C Driver (DISP Module) Self-check programs (DIAG Module) added |

Confirm operations of Display and Indicator (BD1 and BD2, respectively) |

| v0.3 | Display the gain data calculated from readings of VR1 on Console screen.

Newly added VR Driver (VOLM Module) is used to read the voltage of VR1. VR Driver uses PWM (*1) and ADC (*2) Display the gain values on Display (BD1) |

Confrim accuracy and linearity of the reading of VR1 Check the gain data to be set to PGA2310 (*3) Check the relation between the gain data and actual gain |

| v0.4 | Send gain data to PGA2310 Drive Selector Relays according to state of SW2 |

CC-218 works as preamp |

| v0.5 | Console Commands are implemented Setting data are saved in EEPROM |

CC-218 can be controlled by Console Settings, such as brightness of Display, can be changed by Console Commands Self-test programs can be invoked by Console Commands |

| v0.6 | IR Remote Driver (REMT Module) is added | CC-218 can be controlled by Remote Commands |

| v0.7 | DVCS Master Mode is implemented | Send commands to DVCS slave device(s) when CC-218 is in Master Mode |

| v1.0 | Final version WDT(*4) enabled |

CC-218 perfectly meets the specifications |

*1: One of the features of CCP Module (built-in peripheral of MCU chip) --

used to generate square wave of 10kHz, 50% duty

*2: 12-bit A/D converter (built-in peripheral of MCU chip)

*3: Electronic volume chip

*4: Watch Dog Timer -- used to reset CPU when it runs away

For further details of the design procedure, refer to the following document.

<F/W design document: CC-218_FW_Design.pdf>

Debugging method

I believe that the methods for debugging firmware are generally not covered

in programming textbooks. Unlike software debugging—where you use a debugger,

set breakpoints, step through the code, or display variable values—such

methods do not work in embedded systems, which are event-driven and require

real-time responsiveness.

Although I don’t intend to give overly general explanations on this website,

I think firmware design and debugging are largely unfamiliar to audiophiles,

so I’ll offer a brief explanation.

An effective method for debugging firmware is to connect a console to the

target system (CC-218) and display events and status information on the

console screen. What I refer to as "console" is a terminal software

running on a PC. I chose Tera Term 5 for this purpose.

To connect with Tera Term, it’s necessary to enable serial communication

using the RS-232C standard. This is done by using the UART built into MCU

chip. In the case of the CC-218, the UART input and output are connected

to DVCS Port.

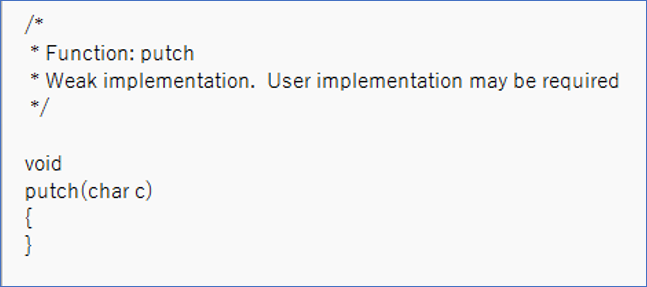

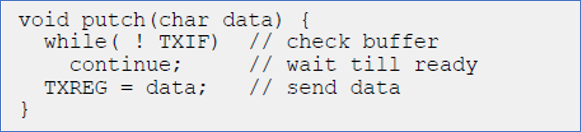

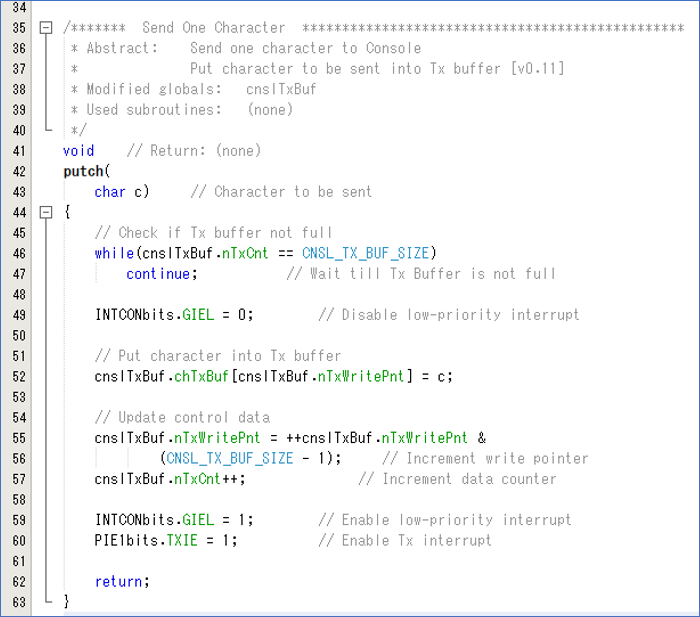

Writing messages to be sent to Console is a lot of work, so I use the printf()

function from the standard library.

To use printf(), you need to create single character output subroutine

called putch(). The printf() function repeatedly calls putch() to send

text.

Since putch() is hardware-dependent, the user must implement it. A template

(skeleton) for putch() is included in a subfolder of the directory where

XC8 is installed. You copy this template into your own source file and

implement the necessary content. I pasted it into the source file for CNSL

Module (cnsl.c).

|

|

| Template of putch() |

Implmentation example of putch() (from the manual of XC8) |

The example in the upper right cannot be adopted because it waits for the

transmit register to become empty. If you wait for an event like that,

the execution time of putch() becomes longer. As a result, printf() also

takes more time to complete, and the task that called printf() ends up

running longer as well. This undermines the system’s real-time responsiveness.

Inside putch(), all it should do is place the character to be sent into

the transmit FIFO buffer and enable the interrupt. The rest is left to

the UART driver.

The figure below shows the putch() routine used in the CC-218 FW. At the

beginning of the routine, there is a while() loop that waits for space

to become available in the transmit FIFO buffer. This was added as a precautionary

measure for least expected cases. Under normal conditions, this loop passes

through without iterating.

In the CC-218 FW, function names and variable names are defined based on Hungarian notation.

|

| Implementation ofputch() (CC-218 FW) |

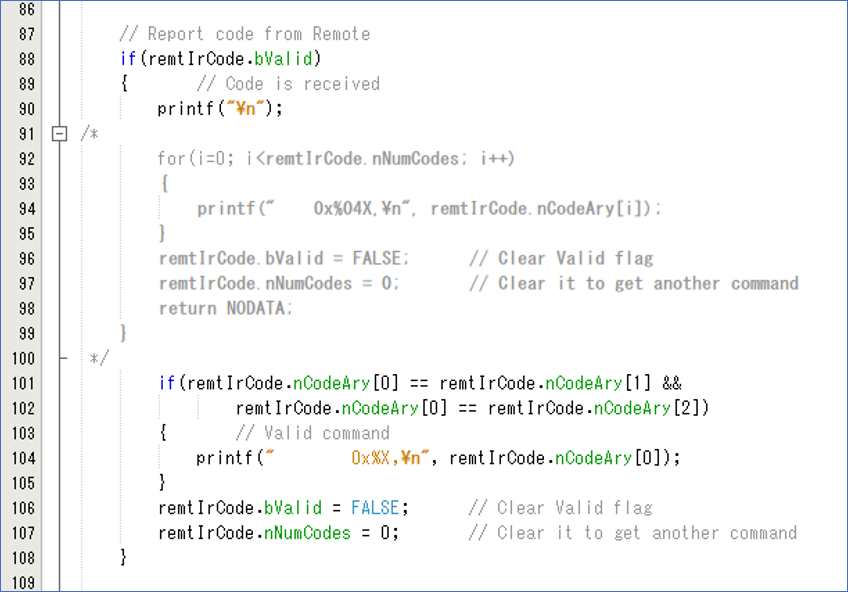

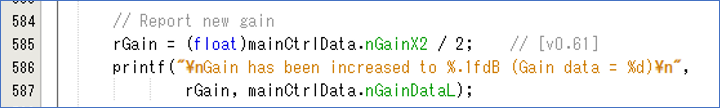

|

| Example of usage of printf() |

printf() is a very convenient function, but it consumes a lot of memory.

In the case of XC8, it uses about 11KB. Since the program memory of PIC18F2520

is 32KB, printf() alone takes up about one-third of it. If it's likely

to run out of memory, you’ll need to stop using printf() and create a simpler,

custom function instead.

In CC-218 FW, the program memory usage stayed within 86%, so printf() continues

to be used.

Tera Term has timestamp and logging features. Enabling both of these features and saving the log can be very useful later on.

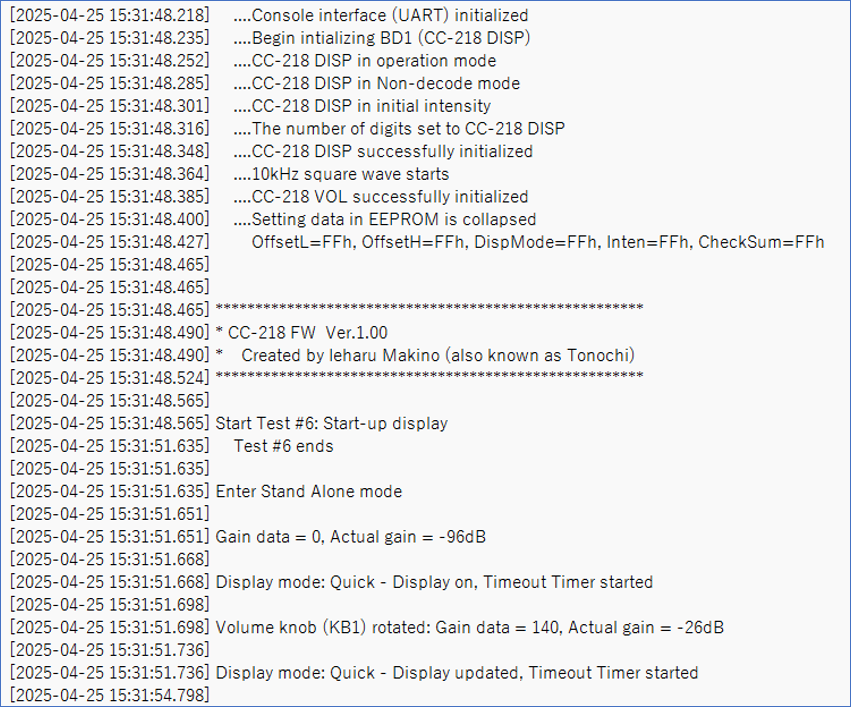

|

| Example of Tera Term log -- Opening message of CC-218 FW |

Specification of IR remote

I believe that among DYI amp builders, few have incorporated infrared remote controls. Though may not be necessary, I’d like to provide a brief explanation of the infrared remote control interface as well.

Japanese companies tend to be closed off, so the specifications for infrared

remote controls are not publicly disclosed. While searching for information,

I came across a certain document (Ref-42, pp.263~274) that provides an

overview of the specifications of Japanese infrared remote controls. It

mentioned the existence of a unified standard called the “Home Appliance

Association Format” and noted that companies like Vishay and NEC manufacture

IR receivers. For details on the reference, please see the page "References."

This book is old (from 2005) and I later found out that it doesn’t reflect

the current situation, it did make one thing clear: Vishay IR receivers

can be used.

After checking Vishay’s datasheet, I decided to use TSOP34838 (although,

as mentioned earlier, I should have chosen the improved version, TSOP34438,

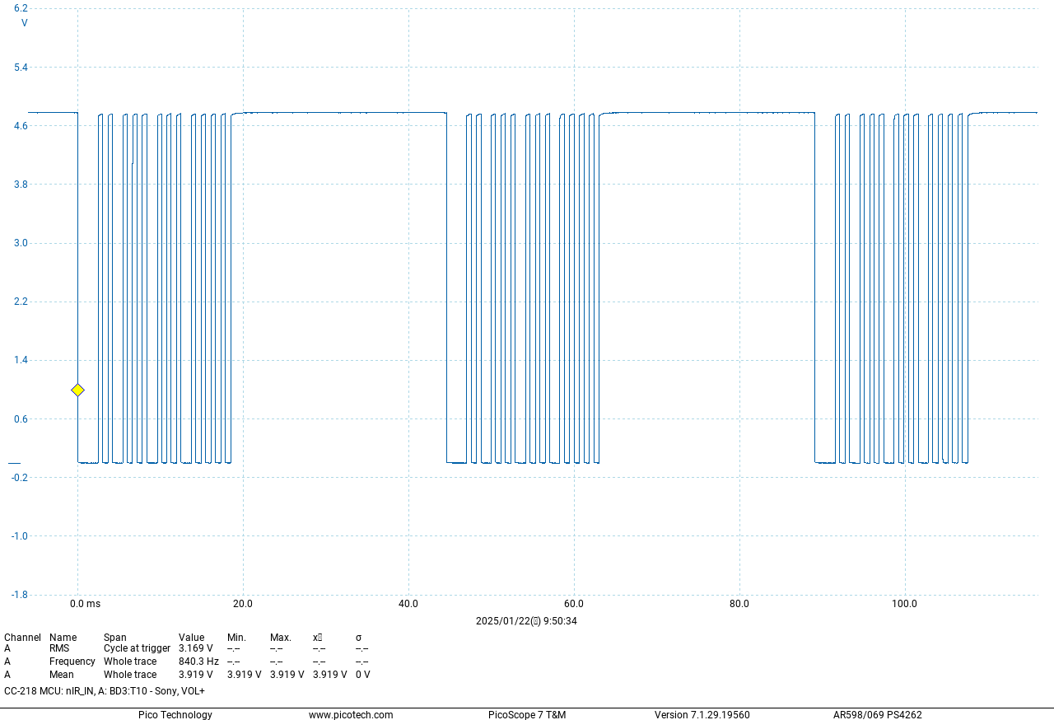

instead). I planned to determine what kind of code was being used by examining

the output waveform of TSOP34838.

|

| Waveform of output signal of IR Receiver When VOL+ button of SONY RM-PZ3D is pushed |

Looking at this waveform, I was able to guess what kind of code was being

used.

I incorporated a routine into the firmware that converts this code into

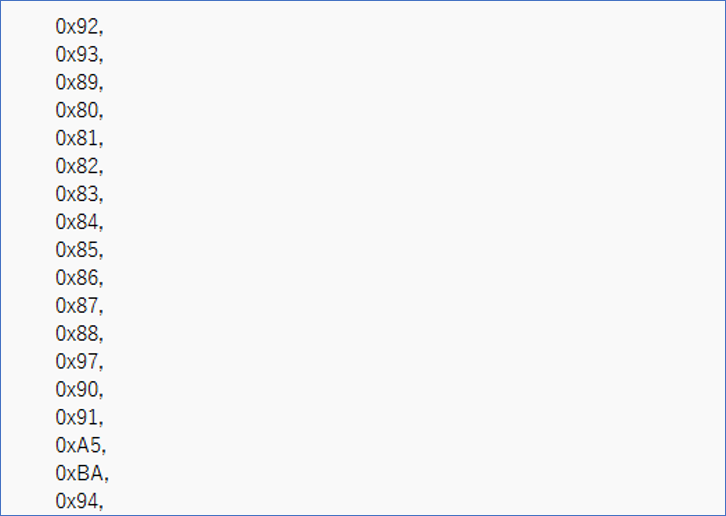

numerical form and reports it to Console. The log below shows the codes

generated by pressing each button on IR Remote.

At first glance, the signal waveform appeared to be outputting 12-bit codes,

but upon closer inspection, I found that the upper 4 bits were always '0'.

Since the buttons could be identified using only the lower 8 bits, I configured

the routine to display only the lower 8 bits (1 byte).

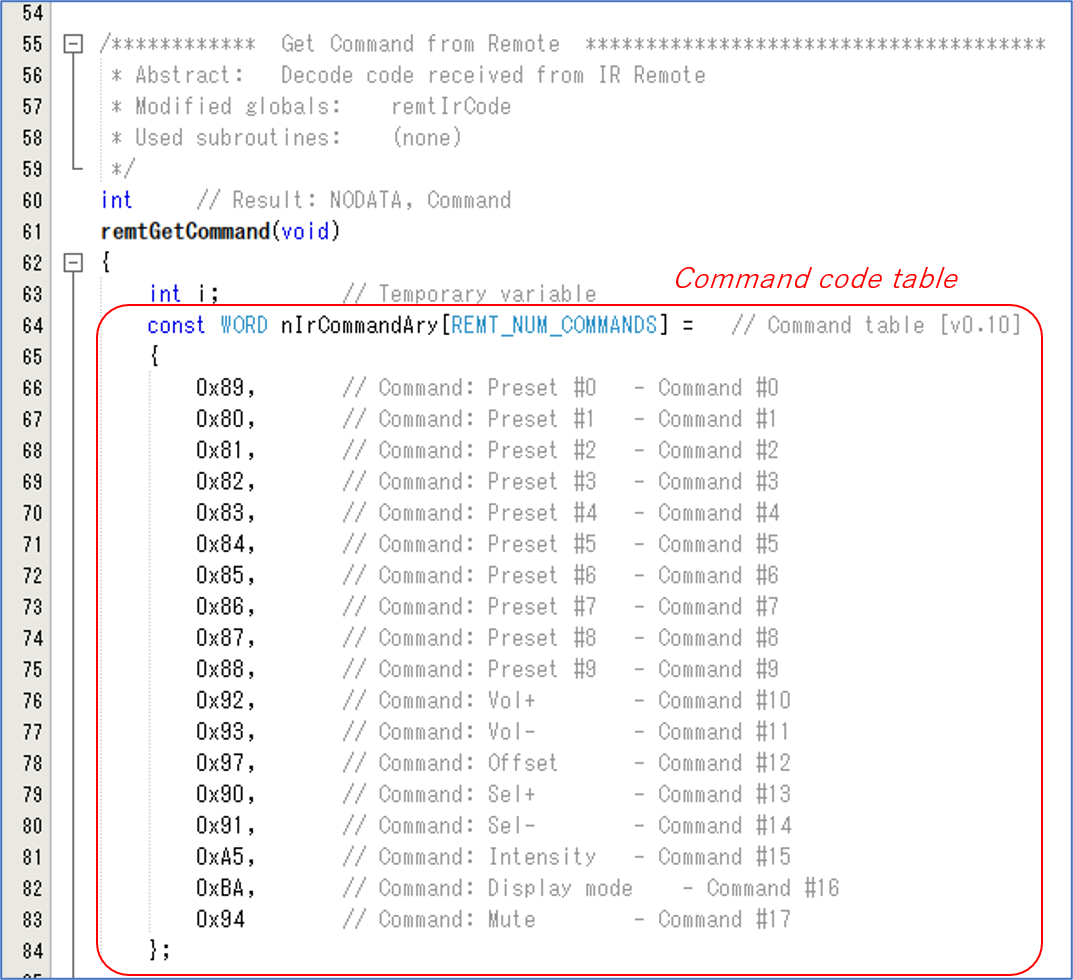

Copy the data from the log shown above and paste them into the source file

of the CC-218 FW (remt.c, specifically the remtGetCommand() function).

Then, edit them to turn it into an array of constants (see the figure below).

The received code is compared with this table (array) to identify which

button was pressed.

|

| Source code of CC-218 FW -- remtGetCommand() in remt.c Command code table created by editing the data copied and pasted from the log file |

Issues concerning PIC18F2520

There was no issue with the PIC18F2520 itself, but I was somewhat concerned

about the quality of its datasheet.

Personally, I’ve never found any errors—even spelling mistakes—in the datasheets

of major American semiconductor manufacturers like Texas Instruments or

Analog Devices. In contrast, Microchip (a UK-based manufacturer) frequently

has simple mistakes and ambiguous expressions in their datasheets. I’d

like to point out one particular issue that made me confused.

In the section "7.8 Using the Data EEPROM," it states (underlined section) that data in EEPROM which is not frequently rewritten needs to be refreshed, and such data should be stored in flash memory. However, in the "Note" section below that, it states something to the effect that data which is rarely rewritten does not need to be refreshed. These statements seem to contradict each other.

|

| Excerpt fromthe datasheet of PIC18F2520 |

The true intent of this statement is as follows:

Due to the nature of EEPROM, writing to one address can affect other addresses

as well. For example, suppose you store two data, A and B, in EEPROM. If

you repeatedly rewrite B while leaving A untouched, A may become corrupted.

Looking at spec D124, it states a minimum of one million cycles. In other

words, if B is rewritten over a million times without ever rewriting A,

there is a risk that A may become corrupted.

What’s troubling about this explanation in the datasheet is that it seems to assume EEPROM will be used as a variable storage area. In the case of the PIC18F2520, EEPROM is located in a different address space from the data memory (RAM). To access EEPROM, you need to use special function registers (SFRs) such as EECON1, EECON2, EEDATA, and EEADR. At the very least, when coding in C, it is not feasible to use EEPROM as a variable area.

In CC-218 FW, the configuration data such as LED brightness and display mode are stored in EEPROM (which is presumably its intended purpose). The data is only rewritten when the user (myself) changes the settings. There’s no way it would be rewritten over a million times in my lifetime. Therefore, CC-218 FW does not perform any EEPROM refreshing.

Building

I carried out the processing and assembly according to the manuals.

Metalwork

<Metalwork manual: CC-218_Metalwork.pdf>

| Processing chassis |

Processing panels |

| Tapping the holes in bar nut | All the metal parts processed |

Processing Wood and plastic parts

<Manual for nonmetalic parts: CC-218_Woodwork.pdf>

| Processing knob Boring screw holes |

Processing acrylic panel Work carefully to avoid cracking the acrylic panel. Use drill bits of φ1.5, φ2.5, φ5, φ8, and φ10 mm to gradually enlarge the holes. |

Temporary Assembly

<Manual for temporary assembly: CC-218_PreAssy.pdf>

Finish

<Finish manual: CC-218_Finish.pdf>

| Painting Painting Top Panel and Side Panels w/ silver metalic spray paint for automobiles |

Front Sticker (ST1) Cut out screw holes after printed w/ PC and printer |

Assembly

Assembly manual (total):

<Assy manual: CC-218_Assy.pdf>

Wire harnesses

<Wire harness assembly manual: CC-218_Design_WireAssy.pdf>

| Wire harness assy WH8 AnalogPower -- Under assembly |

Wire harness assy WH8 AnalogPower -- Complete! |

Modules

The assembly manuals for each module are included in the total assembly

manual.

<Assy manual: CC-218_Assy.pdf>

| Assembly of modules VR Module (Left) and Rotary SW Module |

Boards

I employed PCBs for the first time in this project, and along with it,

the first time I used SMDs (Surface Mount Devices).

Among the SMDs, mounting the AS1115, which comes in a QSOP-24 package,

requires some skill. The QSOP has a pin pitch of 0.4mm, with only a 0.2mm

gap between pins.

A professional can solder it in no time using just a soldering iron. What's more, the result looks so clean, it’s as if it were done with reflow soldering. However, even without professional skills, it’s still manageable.

(1) Use a small amount of solder. Thin solder with a diameter of 0.5mm

or less is ideal (though I used 1 mm solder myself).

(2) Don’t worry if solder bridges form.

(3) Work quickly without lingering. Holding the iron tip on too long may

cause the pad to peel off.

(4) Remove solder bridges using solder wick (desoldering braid).

Although things should have gone smoothly following the steps above, my clumsiness got the better

of me—I ended up failing spectacularly. During the process, the IC shifted

out of position. Once soldered, you can’t remove it without using a special

tool. In the end, both the PCB and the AS1115 had to be scrapped.

Fortunately, I had spares for both the PCB and the IC, so I pulled myself

together and gave it another try. This time, it went well. When I checked

the connections with my DMM and confirmed that the soldering was well done,

I breathed a big sigh of relief.

<Assy manual for Display Board: CC-218_DISP_Assy.pdf>

| Assembly of BD1:CC-218 DISP AS1115 (display controller chip) is mounted |

Assembly of BD1:CC-218 DISP Completed (top) |

Assembly of BD1:CC-218 DISP Completed (bottom) |

<Assy manual for Indicator Board: CC-218_IND_Assy.pdf>

| Assembly of BD2:CC-218 IND Completed -- Wire harness (WH11) and screws are also mounted |

<Assy manual for Controller Board: CC-218_MCU_Assy.pdf>

| Assembly of BD3:CC-218 MCU Completed (top) |

Assembly of BD3:CC-218 MCU Completed (bottom) |

<Assy manual for Volume Board: CC-218_VOL_Assy.pdf>

| Assembly of BD4:CC-218 VOL Rev.A Completed (top) |

Assembly of BD4:CC-218 VOL Rev.A Completed (bottom) |

<Assy manual for PhonoEQ Board: CC-218_EQ_Assy.pdf>

Total assembly

Measurements and Improvements

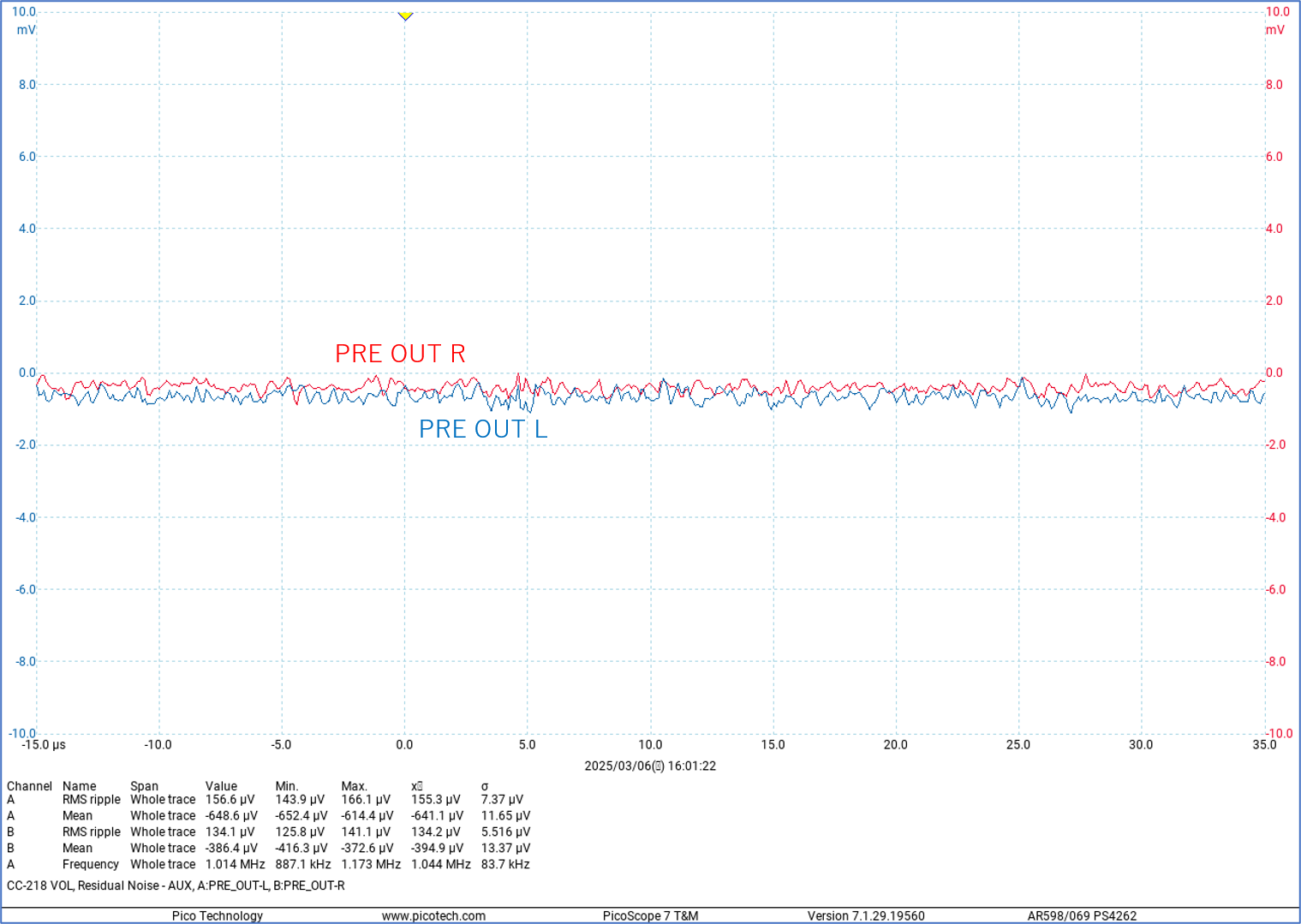

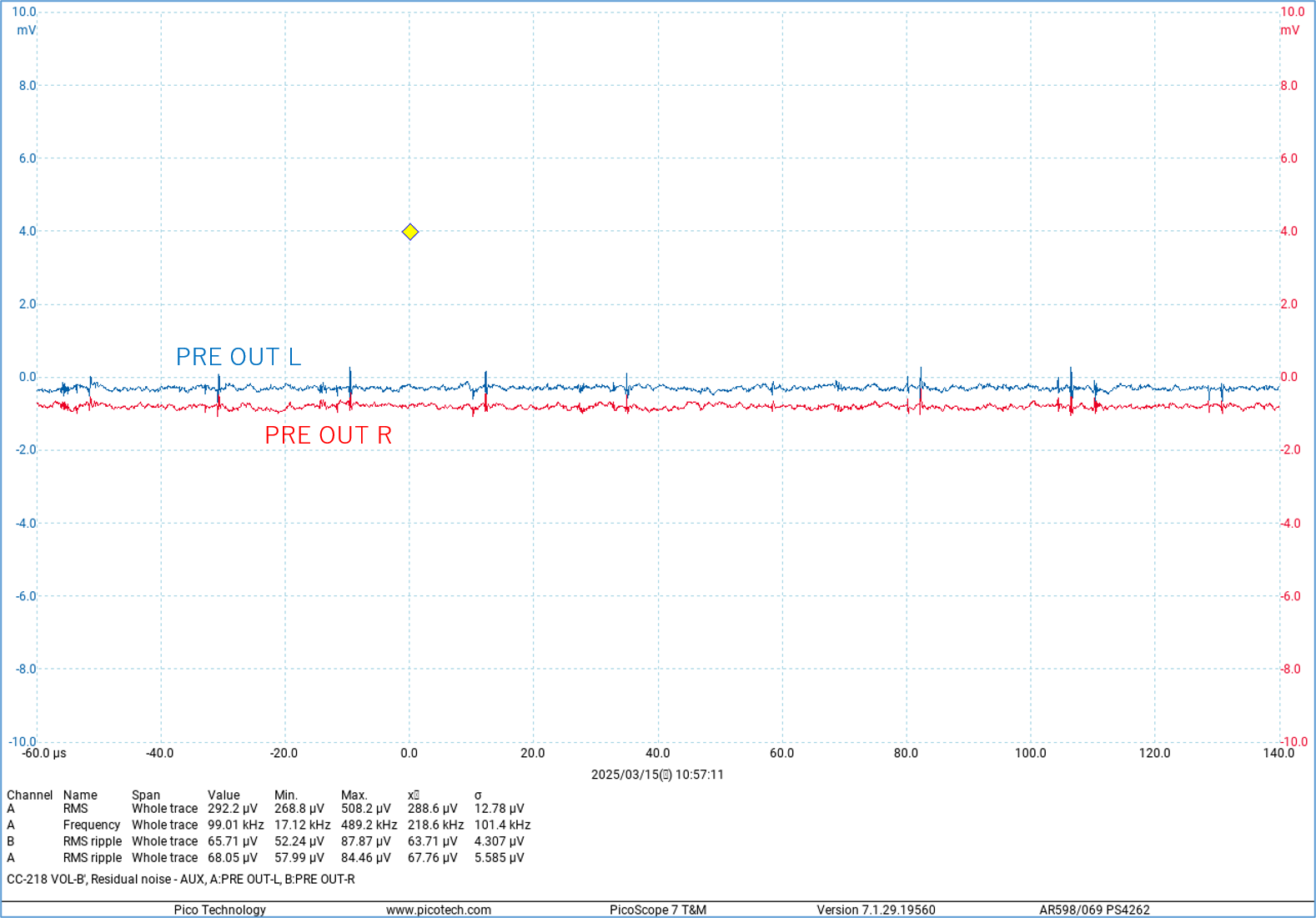

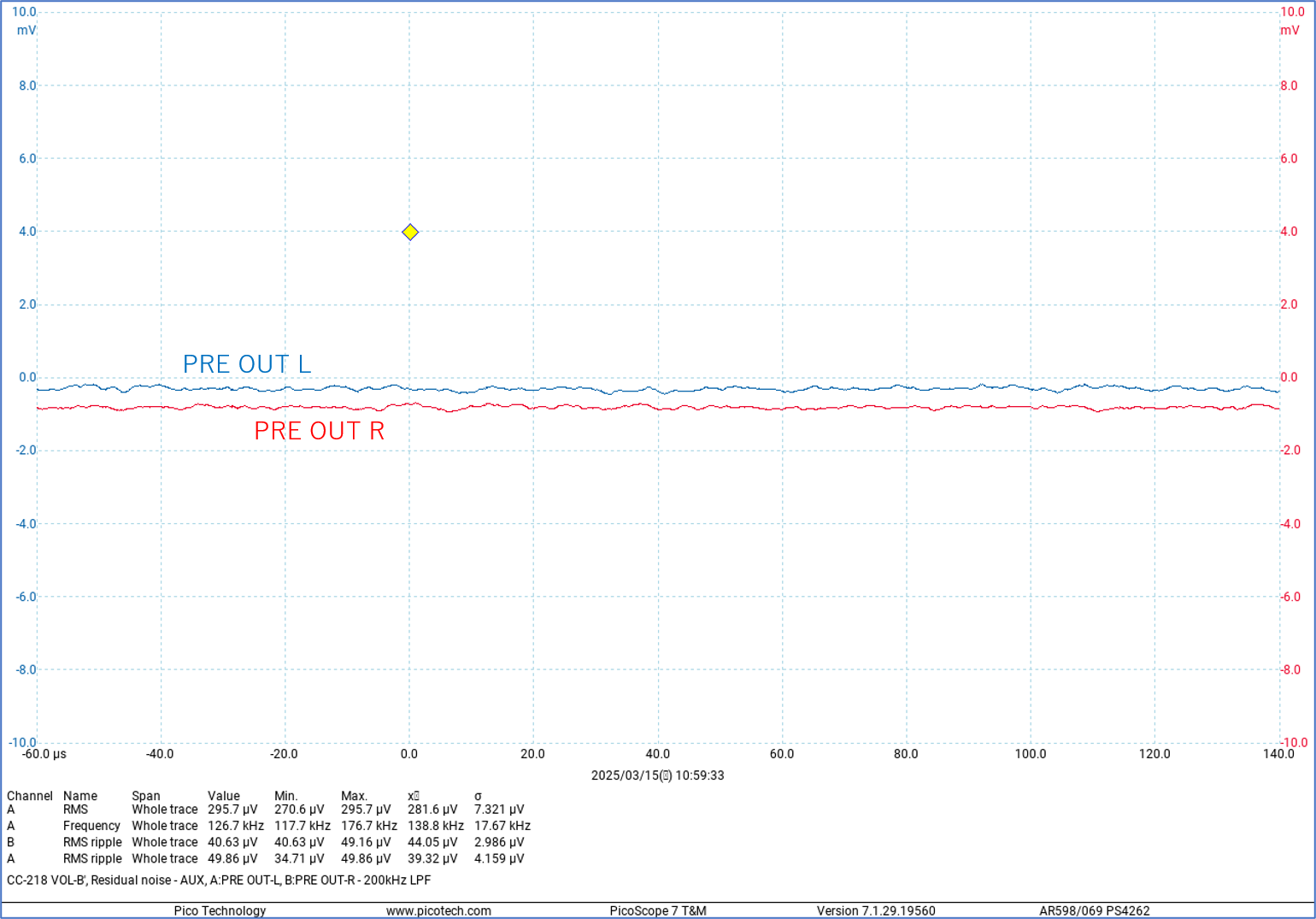

Residual Noise

During the design stage, I was hoping for extremely low residual noise,

but reality wasn't so kind.

Even so, by implementing various countermeasures, I was able to reduce

the noise to a satisfactory level.

Shortcoming of AC/DC converter

For the analog power supply (±24V), I used the AC/DC converters for medical

devices. However, thinking that a regular one would suffice for the digital

power supply, I chose PSK-10D-5-T from CUI. This turned out to be a big

mistake. Measurements revealed that PSK-10D-5-T emits fairly strong electromagnetic

noise.

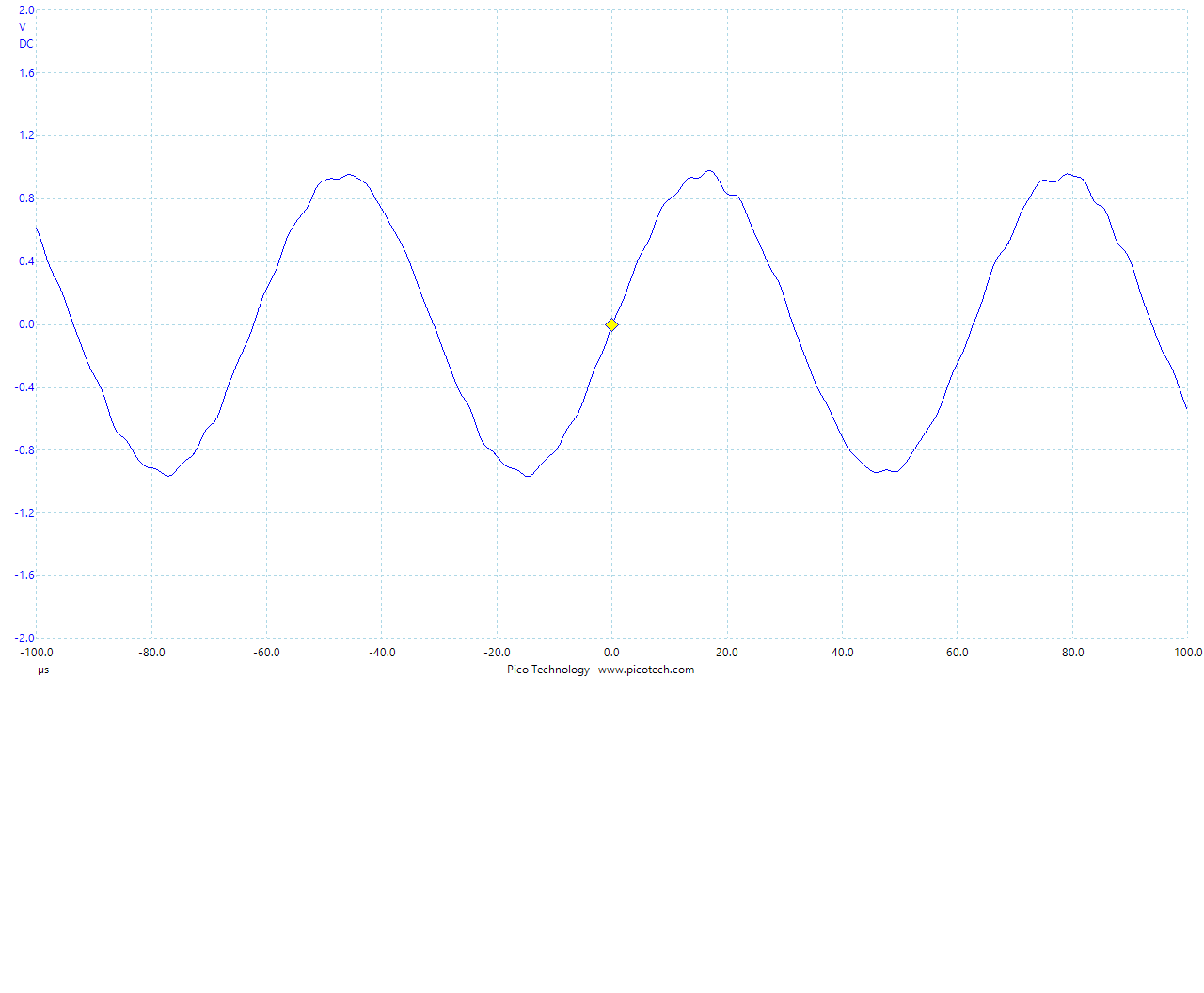

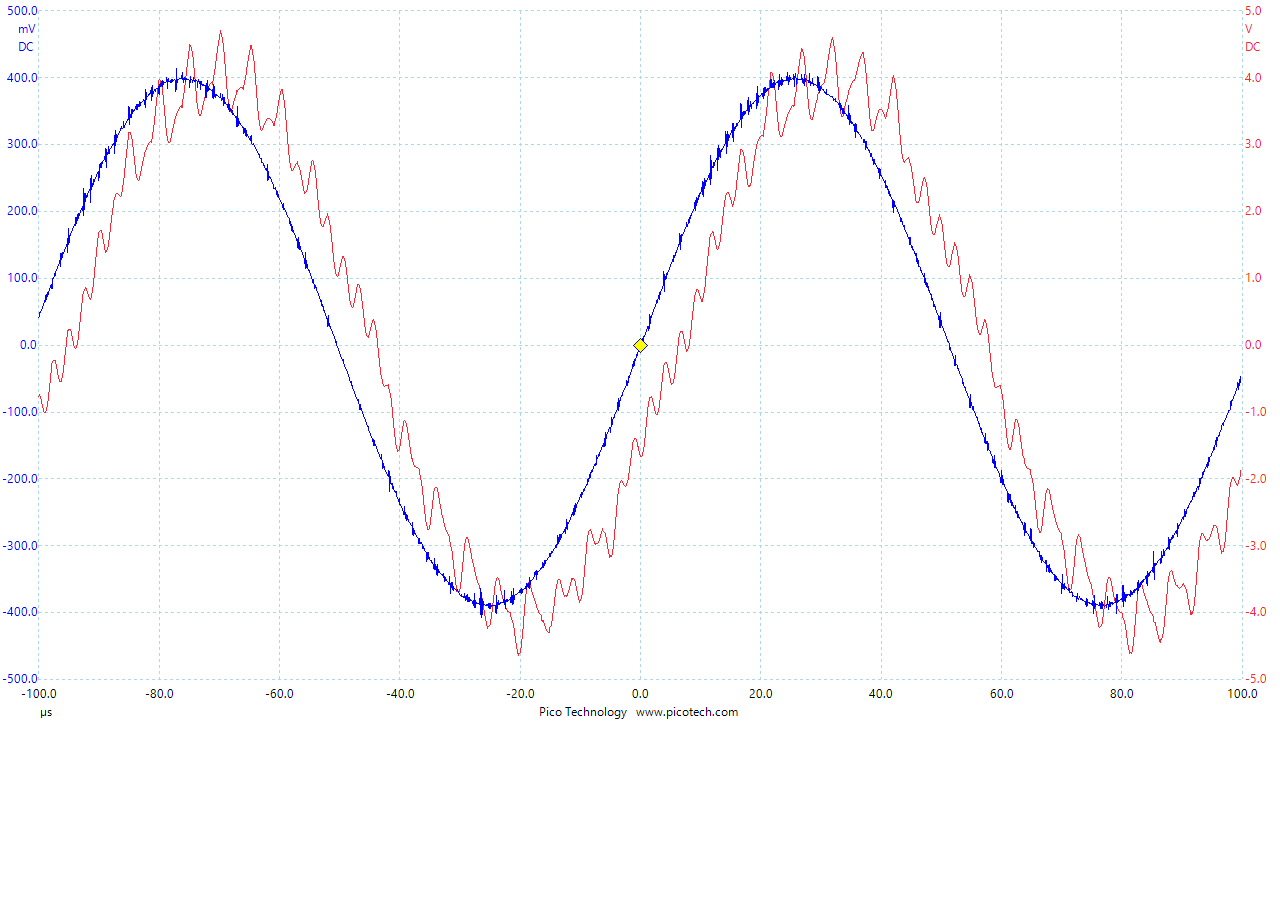

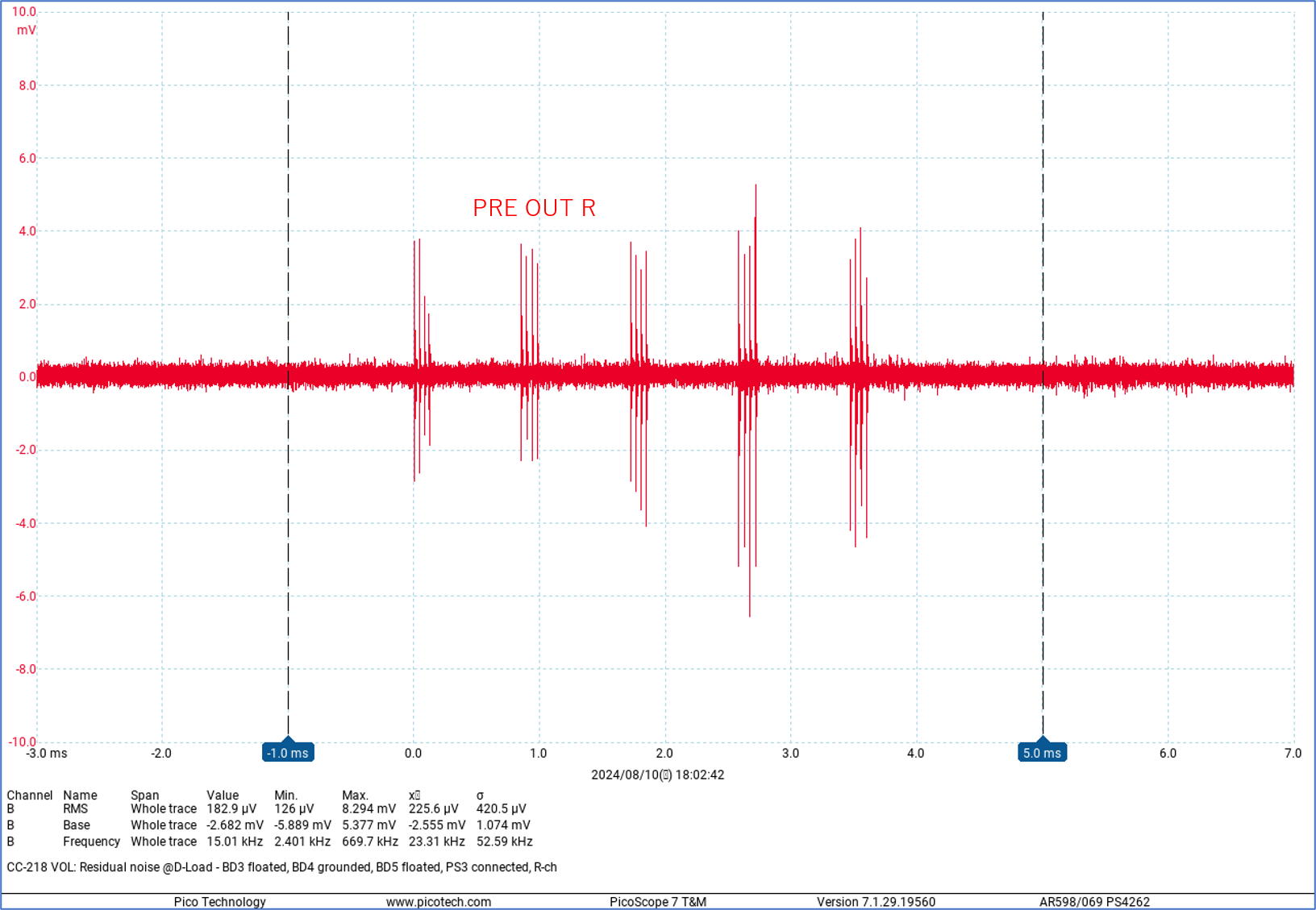

The figure below shows the waveform. Noise with peak values exceeding 5 mV

was captured. This includes not only noise superimposed on the signal lines

but also radiated noise picked up by the oscilloscope probe.

|

| Residual noise of CC-218 VOL -- 1st measurement PRE OUT R-ch Impulse noise occurs periodically |

I decided to replace the digital power supply's AC/DC converter with one designed for medical equipment as well. I chose the EML15US05-S from XP Power, the same model used for the analog power supply."

|

| Residual noise of CC-218 VOL -- After replacement of AC/DC converter PRE OUT R-ch RF noise in the range of 200kHz~1MHz is observed. The RMS value is approximately 130µV. |

SG-FG Connection

I experimented to see whether changing the SG-FG connection point would

affect the residual noise.

The output of Phono EQ Board (CC-218 EQ), which is more susceptible to

noise, was used for observation.

SG stands for Signal Ground. In the case of CC-218, this corresponds to AGND

(Analog Ground) and DGND (Digital Ground). However, on the schemetics of

the boards, AGND is sometimes simply labeled as GND. Similarly, on boards

consisting only of digital circuits, such as Controller Board (CC-218 MCU),

DGND is labeled as GND.

FG stands for Frame Ground, which refers to the potential of the metal parts

of the enclosure.

SG and FG need to be connected at some point in order to equalize their

potential. Once connected, the metal chassis functions as static shield.

In principle, a single SG-FG connection point is preferable. However, according

to what I've heard, commercial amplifiers typically connect them at multiple

points. So, I decided to experiment with multiple connection points on

CC-218 as well.

In traditional terminology, a single-point connection is referred to as

'1-point grounding,' while multiple connections are called 'multi-point

grounding.' Since this terminology is convenient, I will also refer to

them here as '1-point grounding' and 'multi-point grounding' (or 2-, 3-point

grouding).

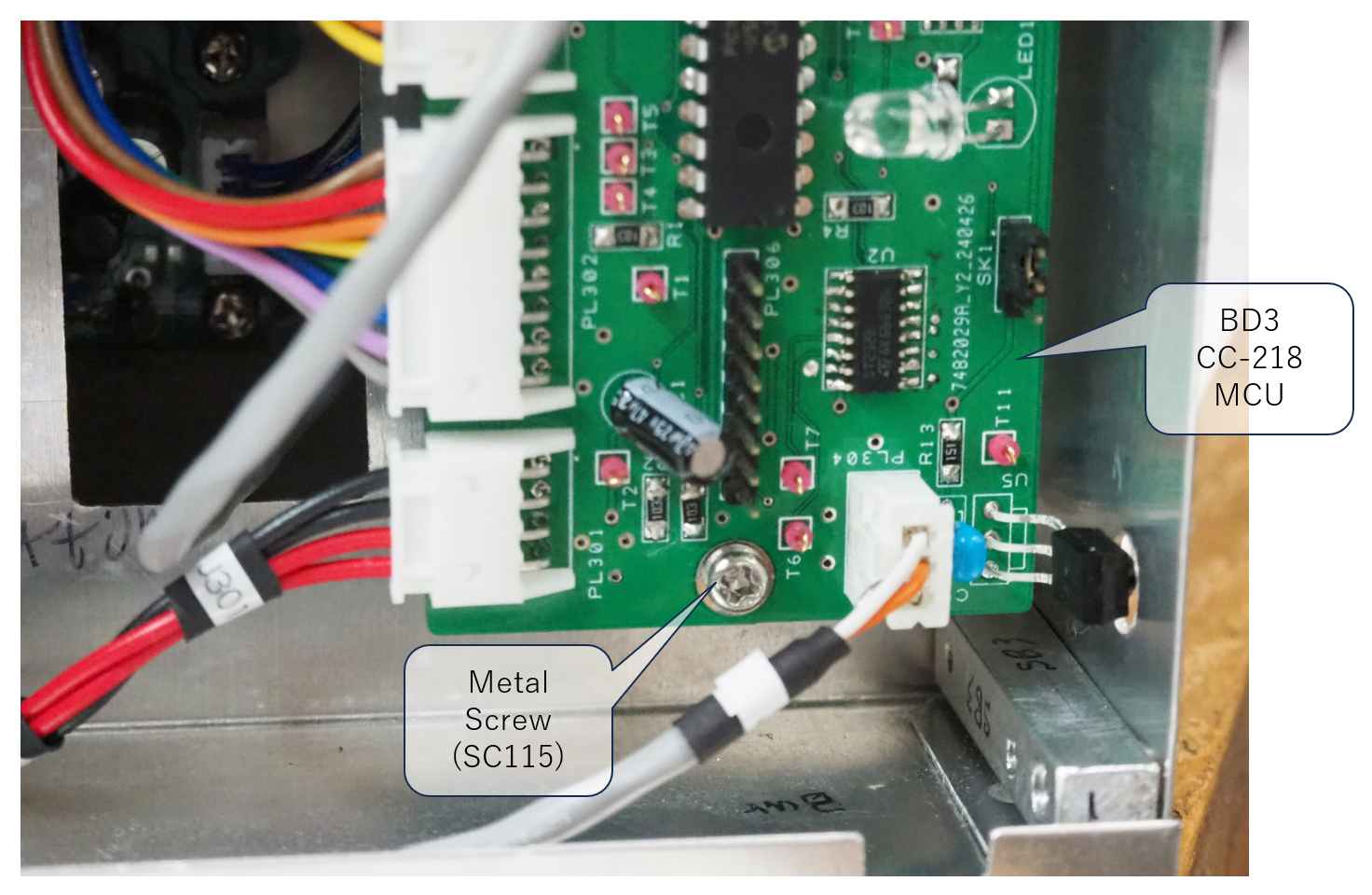

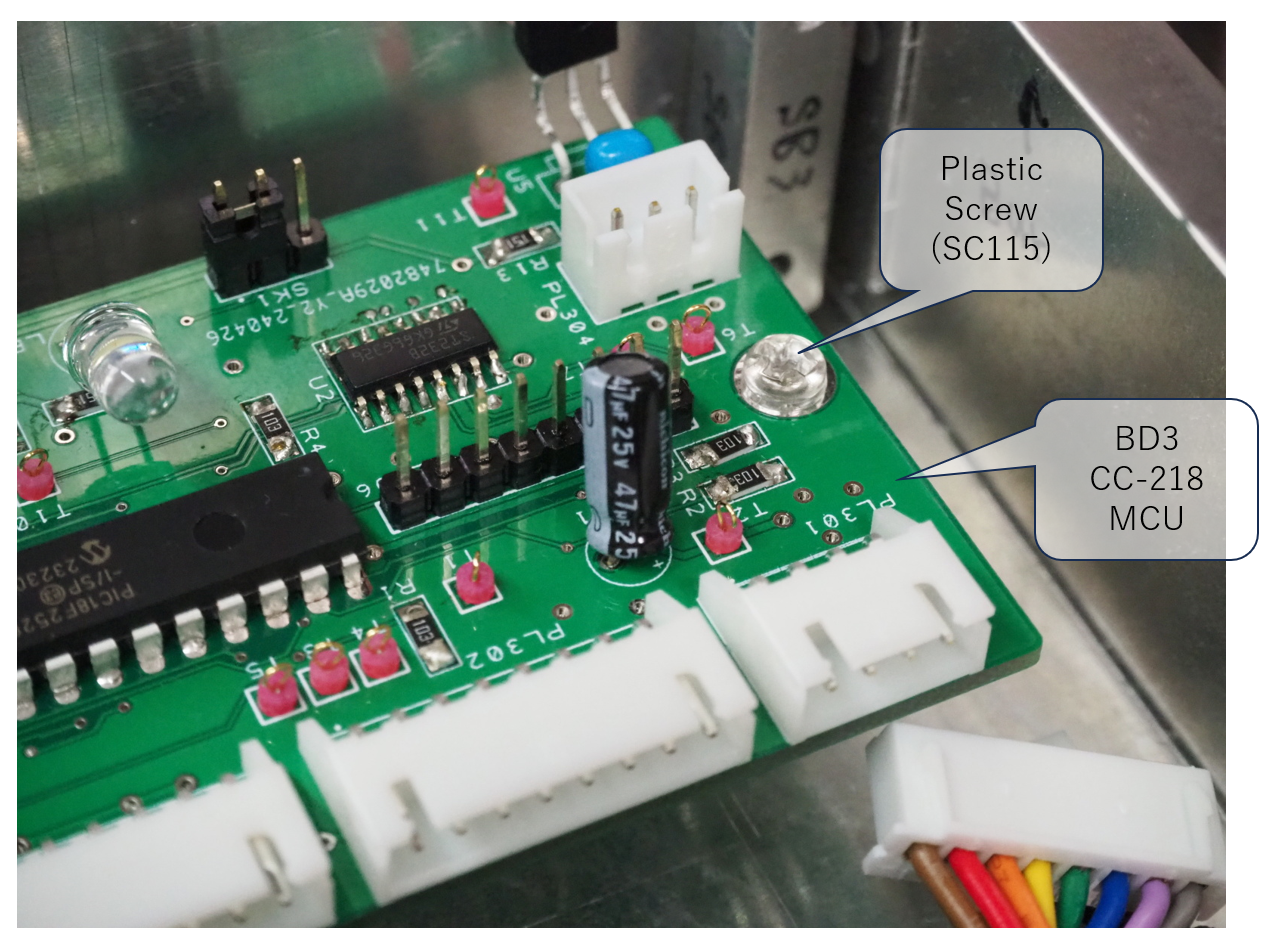

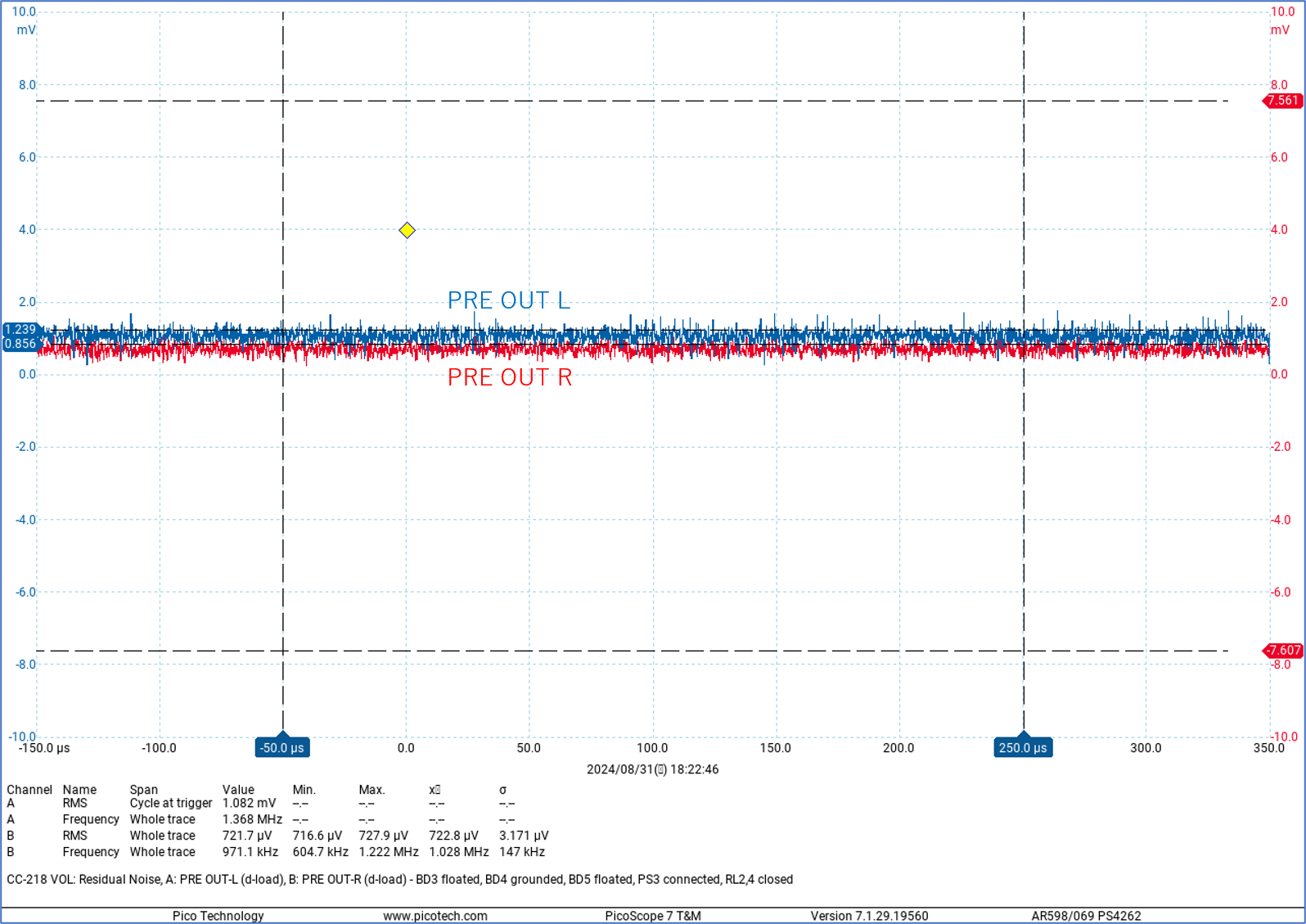

Among the boards of CC-218, BD3 (CC-218 MCU) and BD4 (CC-218 VOL) have one of their screw holes designed as a thru-hole, connected to SG. Using metal screws creates an electrical connection to FG, while using plastic screws and plastic washers isolates them from FG. During the planning phase, I intended to include a pin socket for SG on BD5 (CC-218 EQ) to allow easy connection to the FG terminal on the back panel. However, I completely forgot about this during circuit design, so I soldered a gold-plated OFC wire to the GND track on BD5 to connect its GND (SG) to the FG terminal.

I measured residual noise under the combinations of the grounding points shown in the table below.

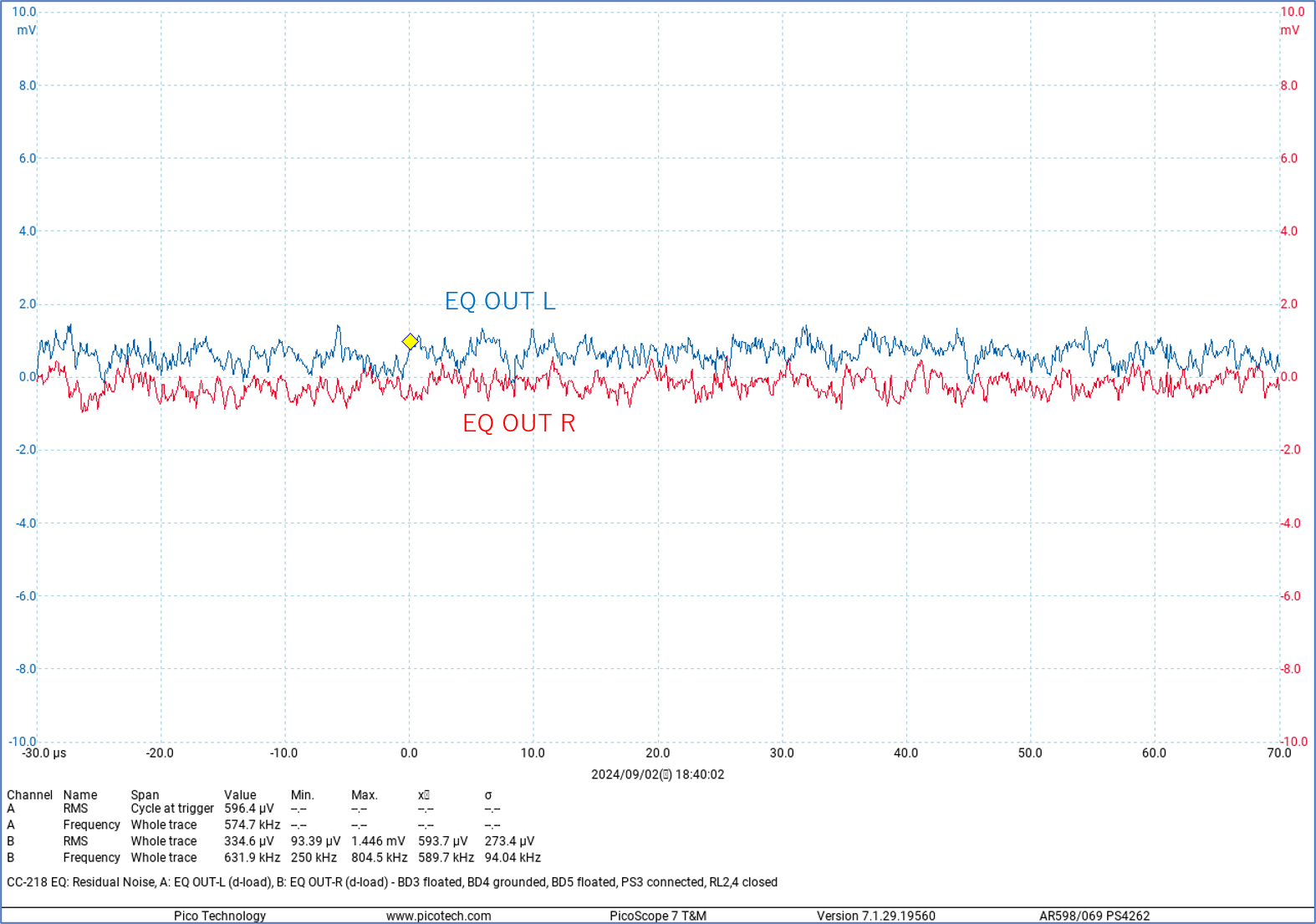

| Condition | BD3 | BD4 | BD5 | EQ OUT L [uVrms] | EQ OUT R [uVrms] |

|---|---|---|---|---|---|

| 1-point grounding 1 | - | SG-FG | - | 684 | 622 |

| 1-point grounding2 | - | - | SG-FG | 637 | 552 |

| 2-point grounding | - | SG-FG | SG-FG | 646 | 629 |

| 3-point grounding | SG-FG | SG-FG | SG-FG | 713 | 681 |

When grounding is done only at BD5 (CC-218 EQ), the residual noise reaches

its lowest level. Since the measurement is taken at EQ OUT, this result

is expected.

Under the condition of 2-point grounding, the noise level does not decrease

compared to 1-point grounding.