SS-309 Trad

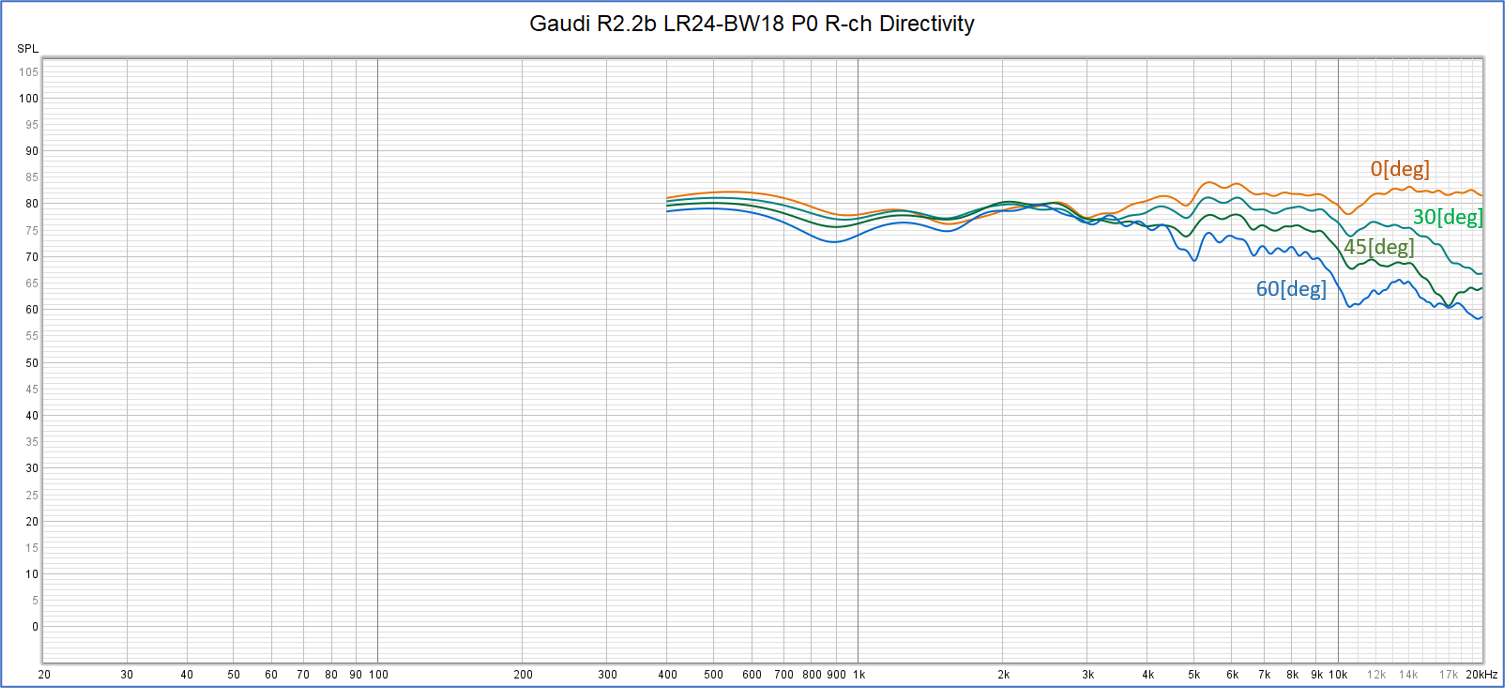

2011/04/03 created

2023/10/16 updated

3-way Speaker Subsystem

Wide-range, Hi-Fi loudspeaker with horn squawker

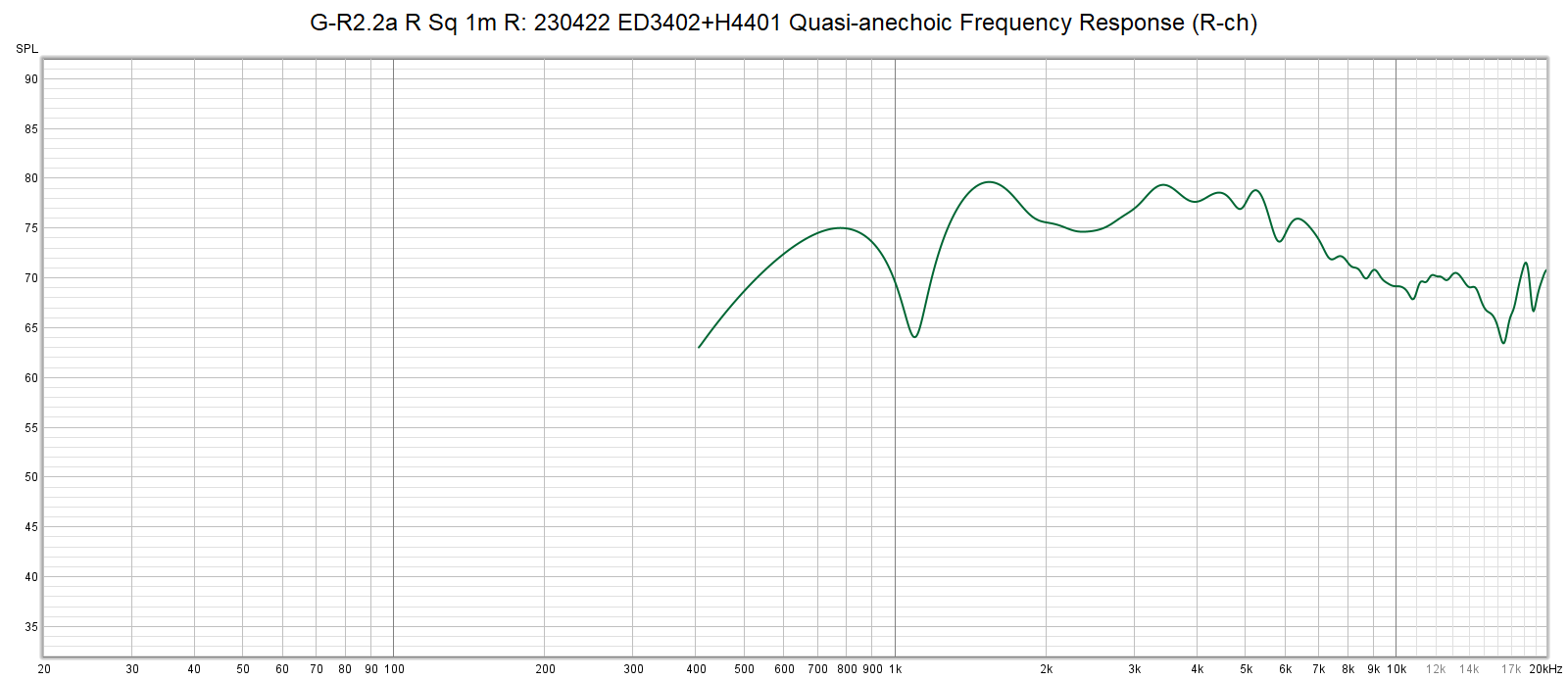

| Configuration | Loudspeaker unit: Fostex T925A (horn tweeter), ClassicPro ED3402 + H4401

(horn squawker), Fostex FW305 (woofer) Enclosure: Closed-box (duct stuffed with urethane mat) |

|---|---|

| Outline Specifications | Frequency response: 25Hz-40kHz. Sensitivity: 108dB/W (tweeter), 106dB/W (squawker), 95dB/W (woofer) (@1m). Dimensions: 402(W) x 752(H) x 352(D) mm (woofer module), Weight: ?kg |

| Cost | Total: approx. 190,000 JPY Tweeter: approx. 56,000 JPY, Squawker: approx. 10,000 JPY, Woofer: approx. 44,000 JPY, Materials of enclosure: approx. 80,000 JPY |

| History | Built in 2001. Revised in 2012 (Rev.A). Revised in 2023 (Rev.B). Being used in Gaudi II. |

The following contents were copied from the page of SS-309 on my previous homepage 'Tonochi's Audio Room'. The page describes my activities concerning this loudspeaker from 2001 through 2012.

Concept

This speaker subsystem was built as the core component in the audio system Gaudi. It is the embodiment of my ideal loudspeaker.

I began believing that a 3-way speaker that consisted of 30cm (12")

woofer and horn-loaded squawker and tweeter was the ideal loudspeaker to

me, just when I took up audio as my hobby at age 13 or 14 (1970-71). This

belief became firmer when I was 16 or 17, when I often stopped by audio

shops in Akihabara and showrooms of audio manufacturers.

In 1974, I designed an audio system that used such a 3-way loudspeaker

, and started building it. It was the beginning of the Gaudi Project. The

first loudspeaker that complies with the system design was SS-307. The

squawker of SS-307 wasn't a horn type since horn squawkers were so expensive.

A full-range LS unit was used instead.

SS-307 was not well-designed. I wasn't satisfied with it. I designed a

new loudspeaker, SS-309, based on SS-307, and built it in 2001.

I am satisfied with SS-309, so I've decided to keep using it in Gaudi II.

I used to call SS-309 'speaker system', but now I call it 'speaker subsystem', because it doesn't include a crossover network and is imperfect as a multi-way speaker.

Nickname and Theme Music

SS-309 hadn't had a nickname. But I wanted a good name for it when I was

planning another improvement (Rev.B) in order to fulfil the requirements

of Gaudi II.

The popularity of Horn-loaded speakers has been declining since 1980s and

they are rare now. I hit upon with the name 'Trad', which means tradition. The word 'tradition' implies that it's old but

still worthy, and traditional things are to be inherited to the next generation.

I'm not an antique lover, but I keep using an old things as long as they

are good in quality and performance.

I chose 'Play Fiddle Play' performed by Isao Suzuki for the theme music.

I wanted to choose a piece of music that features a low-pitched instrument,because

I stick to the large-sized woofer to reproduce deep bass without difficulty.

There are many bands whose leader is a bassist, but only few performances

led by the bass. It's because the bassist is supposed to be a sideman.

The only bassist I know who can play the bass as the lead instrument is

Isao Suzuki. Jaco Pastorius is this type too, but I think Isao Suzuki is

better in this respect.

[Play Fiddle Play (PlayFiddlePlay.mp3)]

Performed by Isao Suzuki Quartet & Kunihiko Sugano (pf) (LP, Isao Sauki

Quartet + 1, Blue City, Three Blind Mice TBM-24)

Hereinafter, the contents are the copy of the page on SS-309 in my previous

homepage 'Tonochi's Audio Room'. The page describes the SS-309 project

from the start of the design in the year 2001 to the replacement of the

tweeters in 2013.

In that period, I had some ideas without scientific grounds, and my way

of evaluation was not strict (because I didn't have know-how in measurement),

and I was strongly influenced by preoccupation (placebo effect) in evaluation

of sound quality. The contents are a bit embarrassing to me now, but I

copy them as they are.

After the copy, I'm going to write my activities concerning SS-309 after March, 2021.

Concept (old)

The concept of SS-309 is an improved version of SS-307. Of course, the

sound quality should be better than SS-307, though, the better appearance

was top priority of this project.

The enclosures of SS-307 were made of ordinary plywood, not painted, only

waxed, and looked shabby. Moreover, after many upgrades and customizes

its appearance had become almost like a junk. My wife often reproached

me, "why did you install those junks in the living room? Throw them

away as soon as possible." It was urgent to build new loudspeakers

that matches the interior of the living room.

I considered that the basic design of SS-307 was so good. As explained

in the page of Gaudi, a three-way speaker system based on a 12" woofer

is my ideal type. Though there are so many types of speakers in the world,

I single out the three-way speaker system as the best. My way of thinking

is simple; for deep bass, a large woofer is the most suitable; for super

high treble, a super tweeter is needed; for the middle range they both

can't cover, a midrange driver should be used.

Of course, I would select a full-range drive-unit if it could produce from

deep bass (25Hz) to super high treble (40kHz) without distortion. But,

in practice, there is no such a drive-unit, and I don't think it will become

a reality in the future, unless a great invention worth Novel Prize is

achieved.

The basic design of SS-309 is the same as that of SS-307: the three-way

multi-enclosure system. The woofer module is placed on the floor, the midrange

module is placed on the woofer module and the tweeter module is placed

on the midrange module. Some might call it only a piled-up speaker boxes

rather than a speaker system. It does not have a network in it, since it

is specialized for a tri-amplified system. The speaker cables are connected

directly to each drive-unit.

As for drive-units, I decided to reuse the ones used on SS-307, because

they were all excellent and I couldn't afford new and higher grade drive-units.

However, the midrange driver, which was originally a full-range driver,

was supposed to be replaced with a horn-loaded midrange in the future.

The midrange module can be switched to the full-range module in Gaudi (and

vice versa). This feature is effective until the midrange module is replaced

with the horn-loaded midrange.

Design

Major Parts/Materials

As mentioned above, the drive-units (loudspeaker units) used on SS-307 were reused.

* Woofer: Fostex FW305 (12" cone type)

* Midrange: Fostex 6N-FE88ES (3.5" cone full-range)

* Tweeter: Fostex T925 (Horn-loaded type)

I believe FW305 is an excellent woofer. It produces comfortably light and

sharp bass. In addition, it can also reproduce deep base like an earth

tremor and dynamic bass that has a strong impact and is felt like a wind

pressure. Its distortion is so low even in the low midrange that it can

be used with rather high fc (the crossover frequency). In my opinion, it

might be superior to W300A, a more expensive woofer produced by Fostex.

6N-FE88ES is one of the best full-range driver I've ever heard. Its sound

is so clear. Most full-range units are not satisfactory because of poor

quality and declining response in high treble region. But 6N-FE88ES produces

so good high treble that it could be used as a tweeter.

T925 is an old tweeter I've been using since 1982. I decided to reuse it

because I didn't detect aged deterioration.

As for the midrange module, as mentioned above, I already planned at that

time to replace it with a horn-loaded driver in the future. I considered

Fostex H400 (horn) and D1405 (driver) as the strongest candidates.

The reason why I singled out H400 was that it was one of few wood horns

available. A metal horn will resonate and produce noise, but a wood horn

not. It is rather hard to eliminate the noise. And, as for the appearance,

a wood horn is apparently better than a metal horn. I wanted a wood horn

at any cost. Only few manufacturers produce horn speakers, and only Fostex

produces wood horns. Among the Fostex wood horns, I chose the smallest

one, H400. Other wood horns were too large for SS-309.

H400 does not need a baffle. To install it, all you have to do is put it

on the woofer module. This easiness is another reason why I chose it.

As for the driver, I have more options, because any drivers with 1"

throat can be used, though, I chose a Fostex again. I'm a fan of Fostex,

because quality of its products is always good, production tolerance is

minimal and reliability is so high. I had two candidates: D1400 and D1405.

D1400 is the top-of-the-line driver using an alnico magnet. I was afraid

that the magnet was so strong that its leakage flux could affect the cartridge

of the record player. And it is often true that the next highest grade

product is more excellent than the highest. Consequently, I selected D1405,

the cheaper one.

I also reused the cables that were used on SS-307, but I don't remember clearly what they were. According to my vague memories, they were:

* For woofer: A coaxial cable manufactured by Mogami Wire & Cable Corp.

I've forgotten its model number. [2015/01/28 corrected] {NEGLEX 2497}

* For midrange: The most popular one among Hitachi Cable's speaker cables

at that time. The color of the sheathe was pink. I've forgotten its model

number.

* For tweeter: I can't remember it at all. But, maybe it was so expensive.

[2015/01/28 corrected] {It was TARA Labs Prism Clara. Not so expensive}

I chose MDF boards for the material of the enclosures. MDF absorbs vibration. It has been spread because of this property. For example, it is often used as floor material of condominiums. MDF boards under a wooden floor prevents noise like a footstep from being heard on the floor below. Though MDF is made from wooden fibers, it is not wood itself. It does not have grain, so there's no limitation for cutting plan. For wood-based material, MDF is not so hard that it is easy to cut and plane it. These properties are helpful for me, who is so clumsy. I decided to create the enclosures with MDF only and not use sliced veneer for finish.

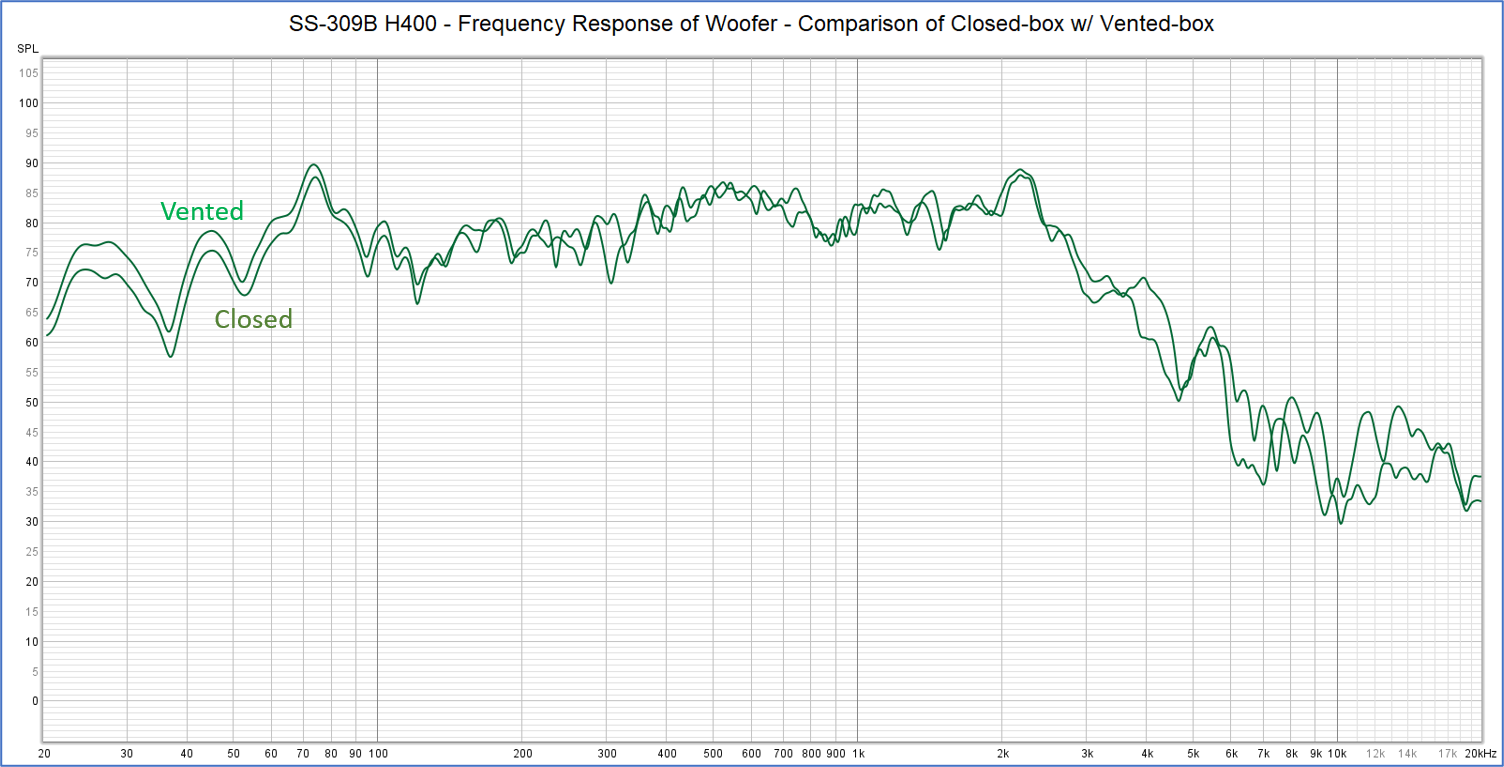

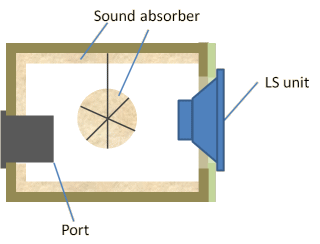

Design of the woofer box

I chose a vented-box system. Though I should have chosen a closed-box system if I had followed my motto, "The best is simple," I didn't because it's difficult to adjust the base response of the closed-box speaker system after it is built. When I designed SS-309, I lived in a condo. I already had a plan to move to a single-family house at that time. So, no choice but I selected the vented-box, which is easy to adjust its bass response.

The targeted lower -3dB cutoff frequency was 30Hz. I decided not to boost bass sound in particular on the assumption that I play music at pretty high volume. Because the preamplifier of Gaudi does not have the loudness and tone controls, it is necessary to turn up the volume high enough to make the frequency response flat.

I determined the dimension of the box by reference to the recommended dimension in Fostex's application note. Exceptionally, I fixed the external width of the box to 402mm so as to fit it to the size of Fostex H400, since I was planning to obtain H400 in the future. The thickness of the walls was 21mm. Not too thick nor too thin. The internal dimension turned to be 360(W) x 710(H) x 310(D)mm, and the internal volume 80l. Though it was slightly larger than the recommended box of 75l, the practical volume is almost same due to volume of bracing.

The joints are not processed in particular. The boards are simply glued

by wood bond. Though wood screws are also used, they are only a supplementary

means. The purpose of them is to keep holding the joints till the bond

dries.

One of the side boards is not glued, and fixed with wood screws only. For

most speaker enclosures, the backboard is detachable, though, the side

board is removed when SS-309 is maintained.

The bass-reflex port (vent) is installed in the rear wall (backboard),

in order to prevent the radiation from the back of the diaphragm from interfering

the sound from the front as much as possible.

A variable-length tube, Tritec BR-70, is employed as the part of the port

assy. The port assy is composed of a small wooden board and the BR-70 fixed

in it. The port assy is screwed to the rear wall. It is easy to adjust

the length of the port, as the port assy is detachable.

[Dimensional drawing of the woofer box (SS-309WooferBox.pdf)]

I utilized an Excel spreadsheet for the design of the port. I had made the spreadsheet by quoting the procedure and the formulas

for designing a port from a book I regarded as a guidebook for building

loudspeakers. It took me only five minutes to design it.

I began designing the port with the target fb (the Helmholtz Frequency) of 30Hz, but it turned out to be 28Hz after

calculation. The length of the port was calculated to be 130mm (the diameter

is 68mm), which was the same as the shortest length of BR-70. BR-70 is

composed of two tubes: the inner and the outer tubes. The outer tube slides

on the inner tube to adjust the length of the port. I discarded the outer

tube and used the inner tube only.

[Spreadsheet for designing the port of the woofer box (WooferBoxPortDesign.pdf)]

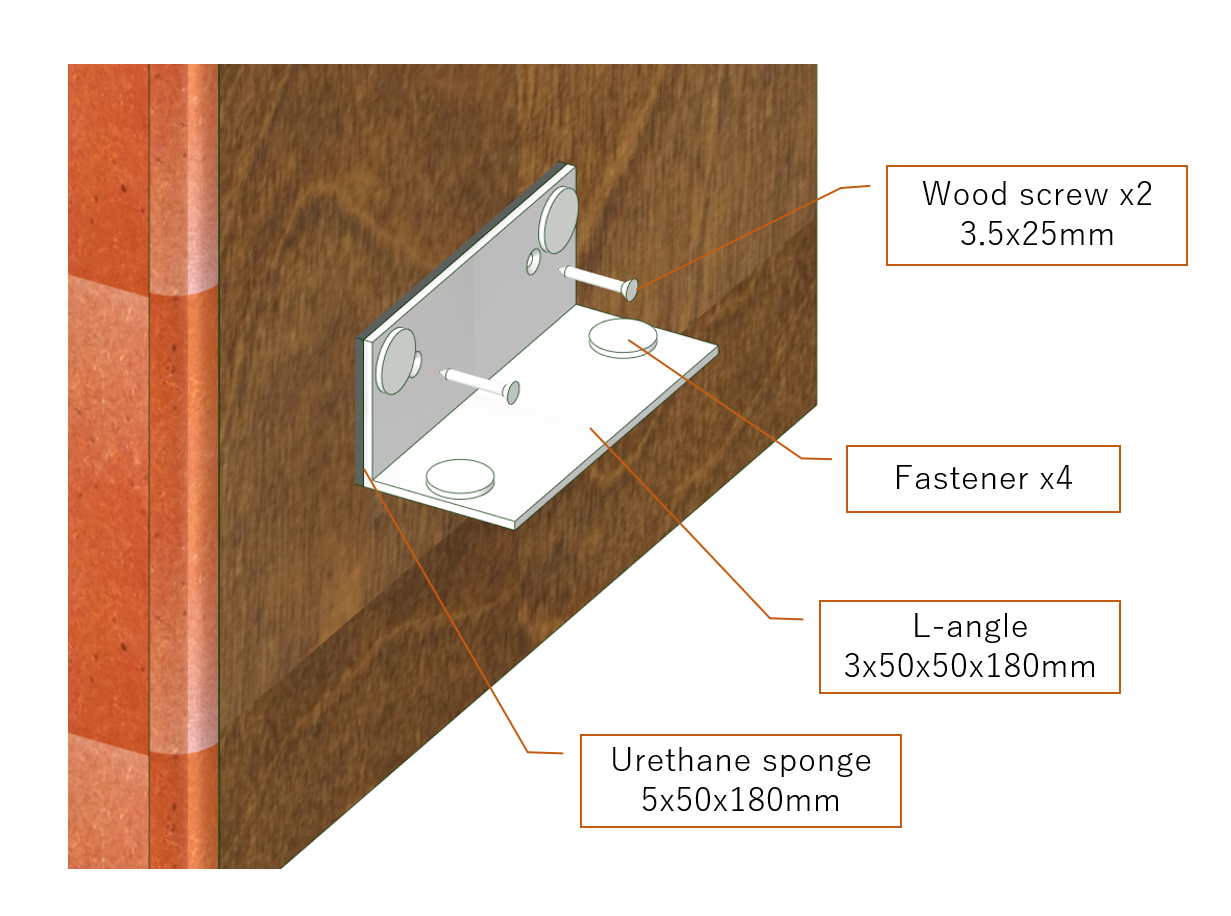

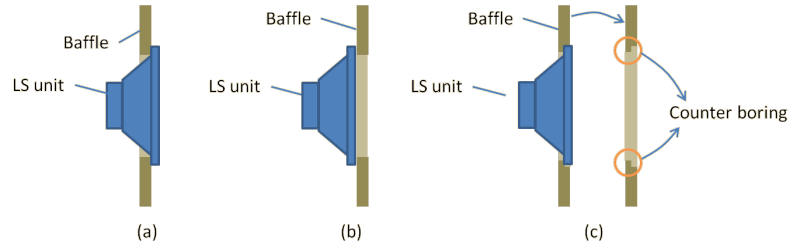

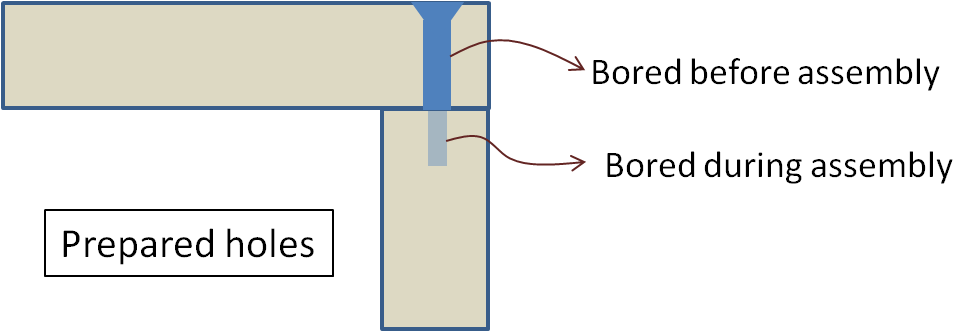

There are chiefly three methods to mount a drive-unit in a baffle as shown in the figure below.

(a) is the simplest method. The drive-unit is mounted on the baffle from

the front. So its advantage is that the drive-unit can be replaced without

disassembling the enclosure. Its shortcoming is that the frame of the drive-unit

protrudes. Unevenness of the baffle surface causes acoustical distortion.

The frame and the baffle should be flush as much as possible.

(b) is a method to mount the drive-unit from behind. This method also has

disadvantage about acoustical distortion. If the baffle is thick, it forms

a circular cylinder attached to the drive-unit. The cylinder adversely

affects the frequency response by making unwanted peaks and dips. This

is called cavity effect.

(c) is a method to reduce the protrusion of the frame by making counter

boring on the edge of the cutout.

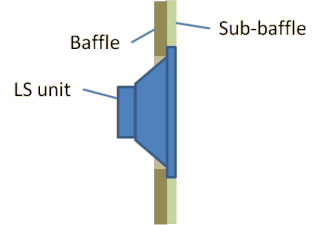

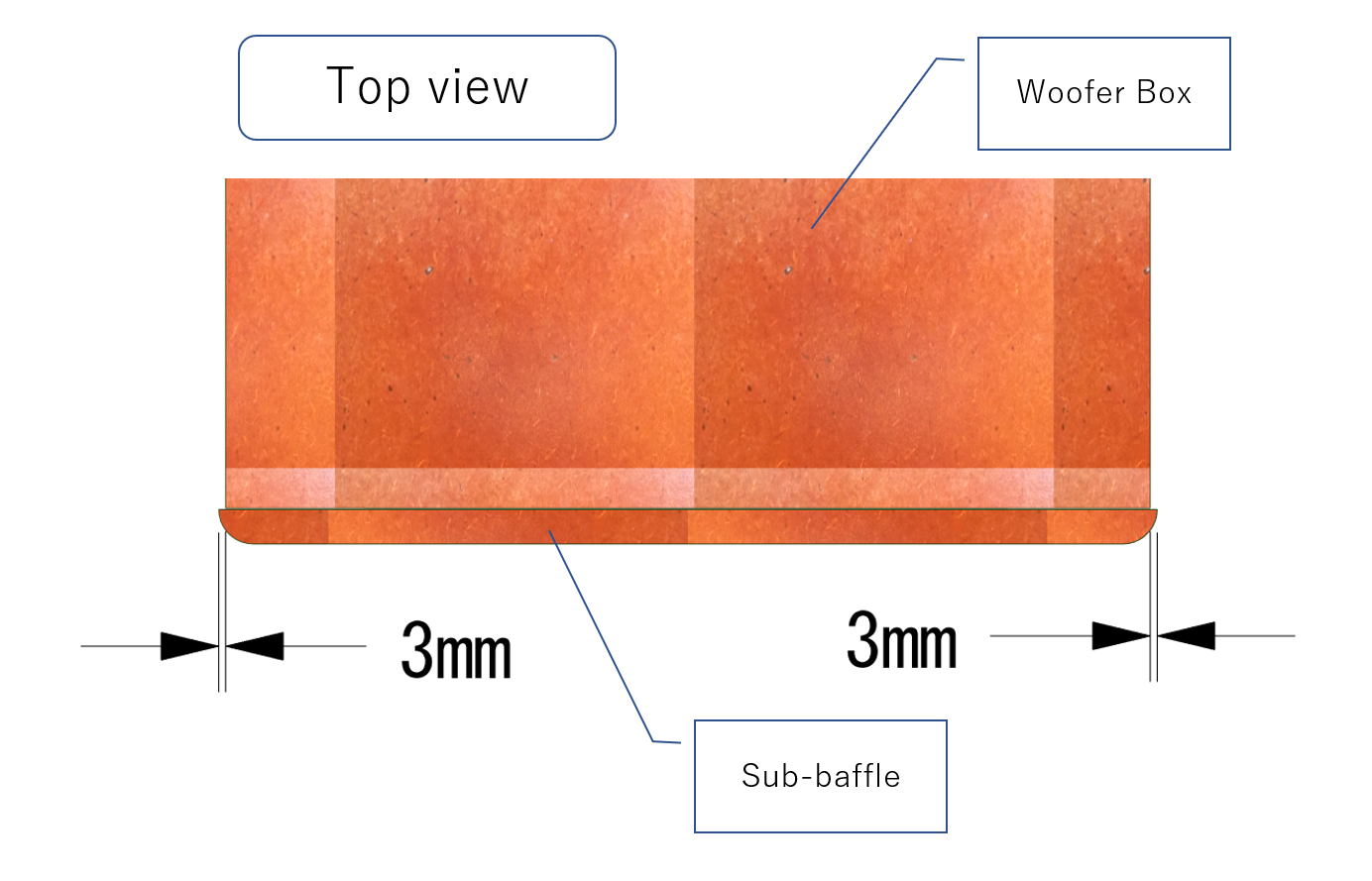

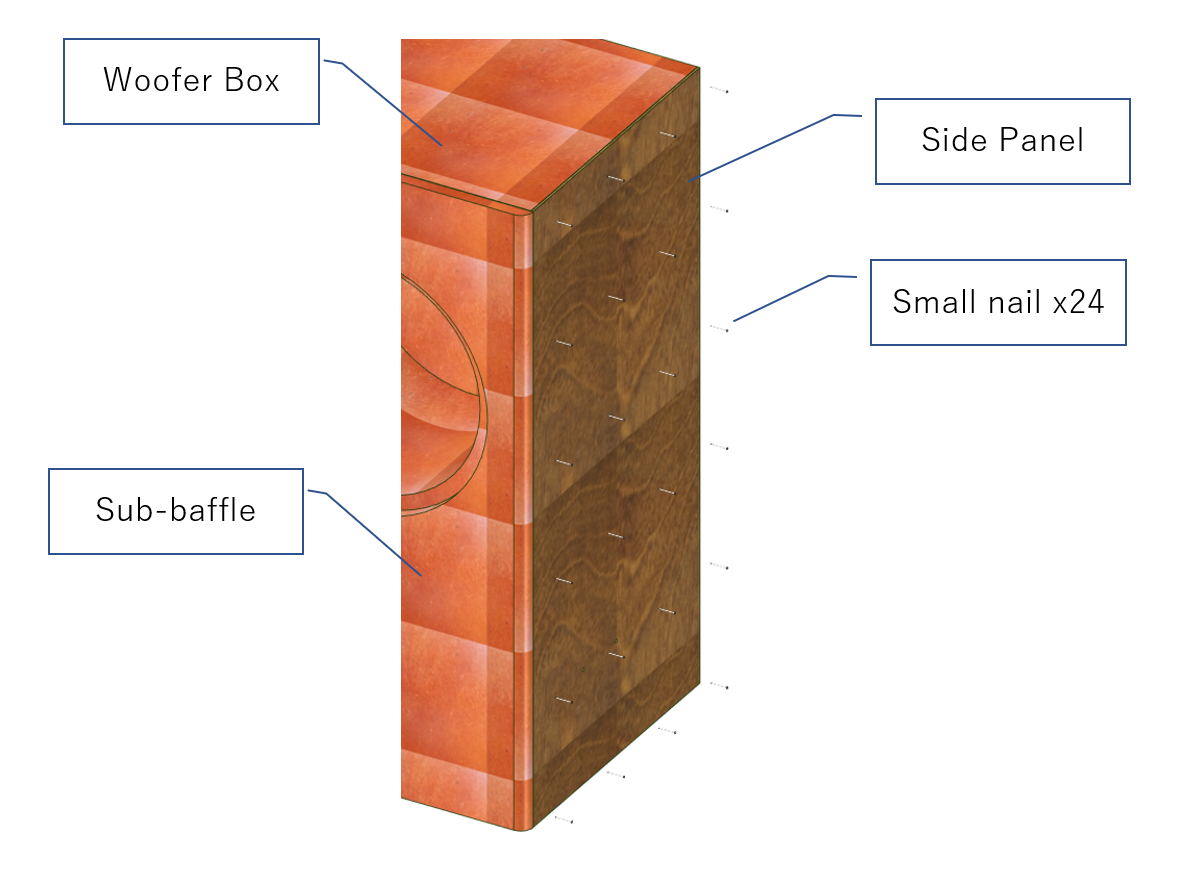

The method (c) seems to be the best, but I am so clumsy that counter boring is too difficult for me. Then, I came up with a good idea. In addition to the method (a), a sub-baffle is added to make the frame of the unit and the baffle surface flush. The thickness of the sub-baffle has to be the same as the protrusion of the frame. It was 15mm for FW305. The sub-baffle cutout for the unit is slightly larger in diameter than the frame.

This method has a couple of more advantages rather than making the baffle

surface flush. The thickness of the baffle becomes as thick as 36mm in

total, so the mass of the baffle increases too. Holding the drive-unit

at a point firmly is another important function of the enclosure other

than keeping the drive-unit's backwave in the box. The heavier baffle has

the greater inertia. Though it is not great enough to be called the mechanical

earth, it surely keeps the drive-unit's frame from vibrating. And, the

edge of the cutout is stronger than the counter-bored edge.

The sub-baffle is screwed on the baffle. It's not bonded to make it removable.

In case of a fault of the drive-unit, there is a possibility that the same

model is not available at that time. The removable sub-baffle can be replaced

with one that fits another drive-unit.

Three kinds of materials are used for bracing of the enclosure. 18mm square spruce pine bars are used as bracing in each corner between all internal walls so that it forms a rectangular frame inside the box. A 40mm diameter cypress bar is used to connect the baffle and the backboard. The walls except the top and the bottom walls are reinforced with 30mm square lauan bars. The dimension and mounting position of each bracing part is shown in the dimensional drawing of the woofer box in blue ink.

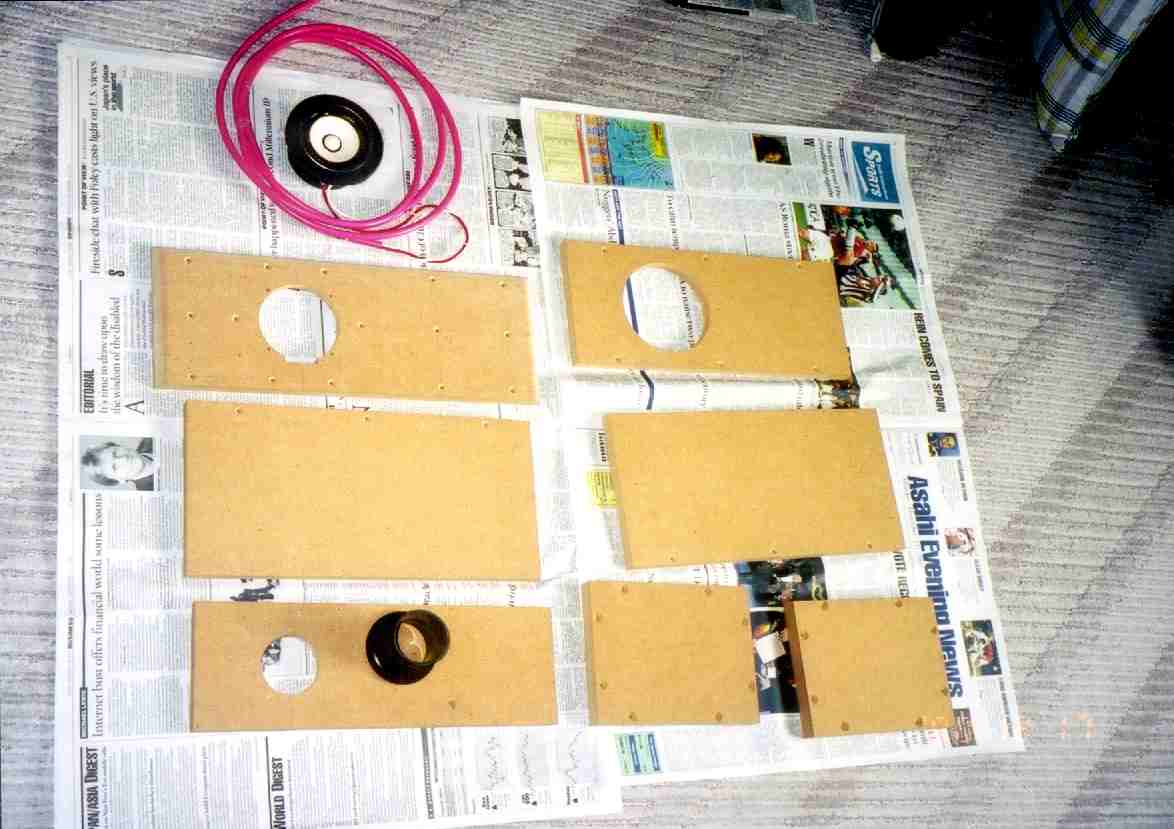

I purchased two pieces of 21x1820x910mm MDF and one pieces of 15x1820x910mm MDF. The parts of both the woofer and midrange boxes are cut out of those three pieces of MDF. In the cutting plan, each part is marked with a symbol (one alphabet) shown in the table bellow. There are different sizes of parts with the same symbol; the larger one is for the woofer box and the smaller one is for midrange box.

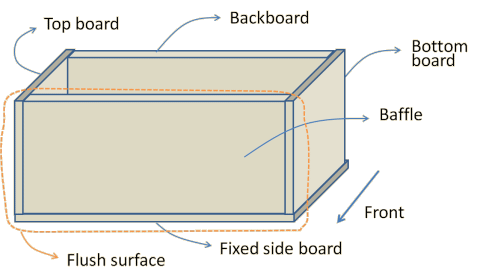

| F | Baffle |

| S | Side board |

| K | Backboard |

| T | Top board |

| B | Bottom board |

[Cuttingplan (CuttingPlan.pdf)]

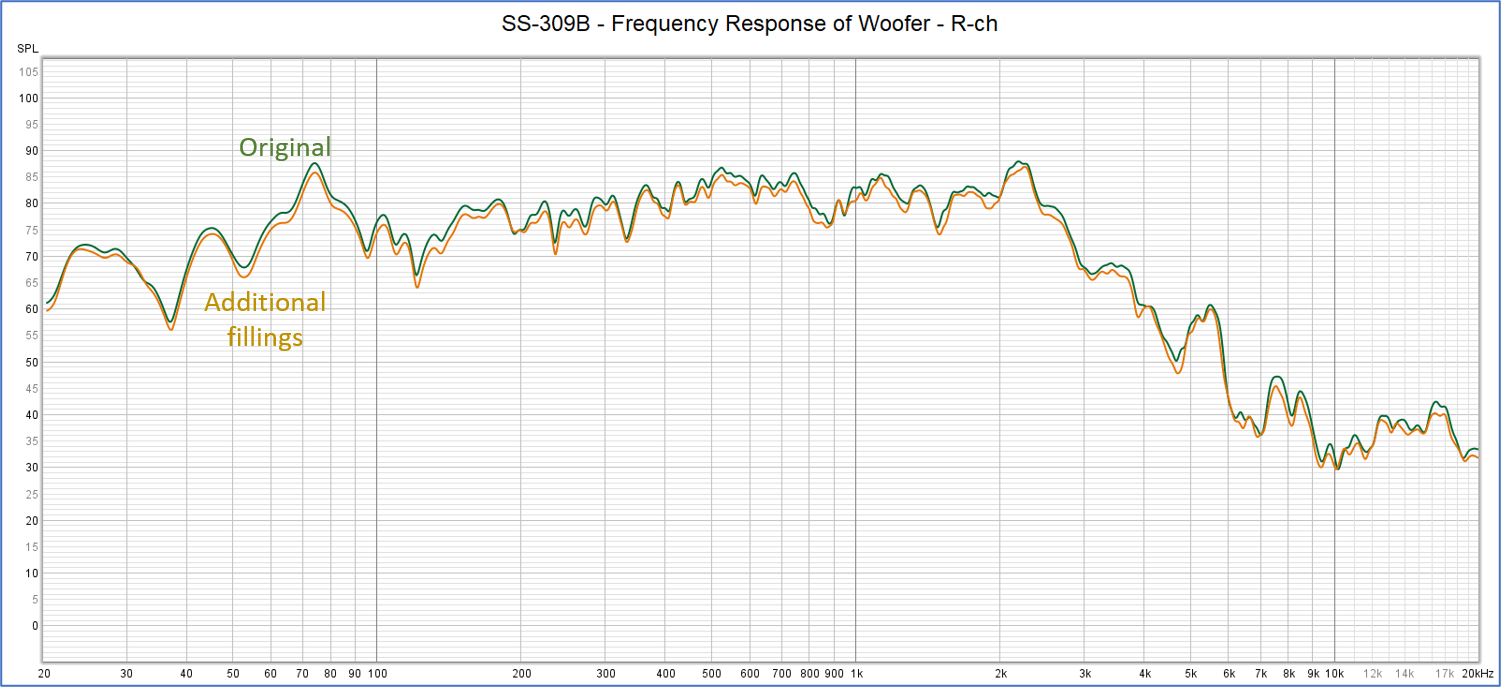

I selected to Micron Wool manufactured by Nihon Muki as filling. Because its fiber is more minute than that of glass wool by far, its degree of sound absorption is so high that even a small amount of Micron Wool works effectively.

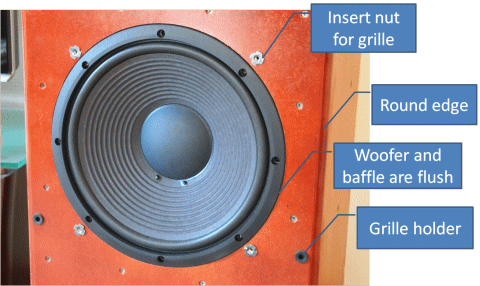

It's generally believed that an acoustical distortion occurs due to diffraction phenomena if the edges of the baffle are not rounded. In practice, the distortion

is so small that it doesn't affect sound quality. Actually, there are many

good loudspeakers with the baffle not rounded.

However, I decided to round the edges of the baffle (sub-baffle, more precisely),

because the rounded edge has decorative value too.

For this purpose, I was going to make a special tool. I described it later

(see "Building").

Dimension errors of the parts may cause unwanted gaps and/or protrusion when the box is built. I came

up with an idea to bring all the errors to the back wall side.

(1) Put one side board (hereinafter referred to as the fixed side board)

on a level workbench. (2) Assemble the parts except the other side board

(hereinafter referred to as the detachable side board) on it using wood

bond. (3) Slide each part to make the baffle side flush. Since the parts

are not mortised, they can be slid a bit while the bond is wet. (4) Make

flush the top board side. (5) Screw all the parts with each other.

The kerfs that joint the detachable side board are made flush with a sander,

and rubber sheets are affixed to retain the box air-tight.

The sub-baffle is screwed on the baffle after the box is completed.

I wouldn't like to do something special to finish the enclosure. Anyway, I don't have a proper place to paint it, so I couldn't

do anything special. However, the most important goal of SS-309 was excellent

appearance, so I considered what I could do for it.

When I looked at a real MDF, I knew the surface of MDF is so smooth that

it could be painted after a little sanding. I chose spray colored varnish,

because it seemed to be the easiest mean. The color I chose was maple.

After the varnish was sprayed and dried, instant lettering was affixed

on it, and finally clear varnish was sprayed.

The grille are indispensable item too. Though I don't care if the drive-units are

showing (rather, I like it), my wife hates that not only the drive-units

but also any other things mechanical are showing.

The frame is made of 18mm square spruce bar, which is also used for bracing

of the enclosures. The net is stapled on the frame, after it was cut to

the appropriate size. In order to make the grille detachable, commercially

available grille holders are used. The male parts are screwed on the grilles,

and the female parts are hammered in the baffles.

For your information, I bought all those accessary parts: the net, the

grille holders, the Micron Wool, and Tritec BR-70, at Kimura Musen located

on the fourth floor of the former Radio Kaikan at Akihabara.

[Drawing of the woofer grille (WooferGrille.pdf)]

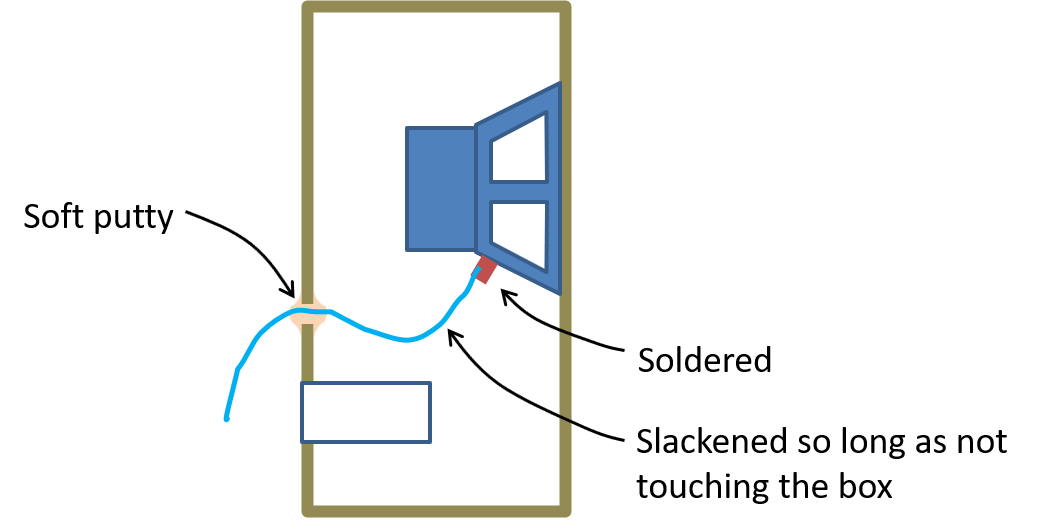

The cable is soldered directly to the driver's terminal, and drawn out of the enclosure

without any terminal. Although it needs a lot of labor to replace the cable

in the future, I chose this direct cabling method, because I learned through

long experience that a contact in a low impedance path through which a

large current flows will impair tonal quality.

Design of the midrange box

The midrange box is also a vented-box system so that it can be used as the full-range module. The port (vent) is installed

in the back wall like the woofer box.

6N-FE88ES is specially designed for a backload horn system, and the maker's

recommended enclosures are backload horn systems. Because its vibration

system is overdamped, it was anticipated that the volume of bass sounds

would not be enough. But, I didn't consider particular countermeasures

like raising Q to make a peak in the low frequency band. And I aimed to

make the frequency response as flat as possible at frequencies higher than

the lower cutoff frequency, in return for setting it relatively high. The

response at the frequencies lower than the cutoff frequency would be sharply

cut off like a typical vented-box speaker system.

The f0 of 6N-FE88ES is 110Hz, so I set the target fb to 100Hz, and designed the

midrange box by the same way as the woofer box.

[Spreadsheet for designing the midrange box (MidrangeBoxPortDesign.pdf)]

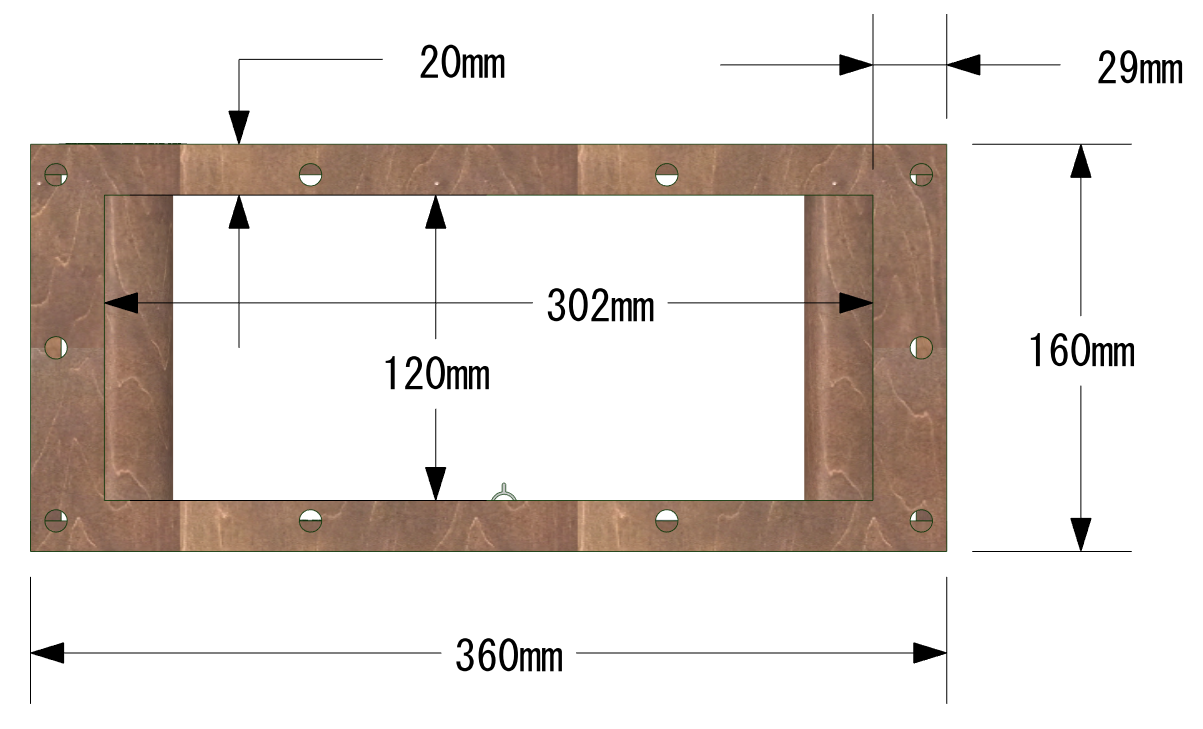

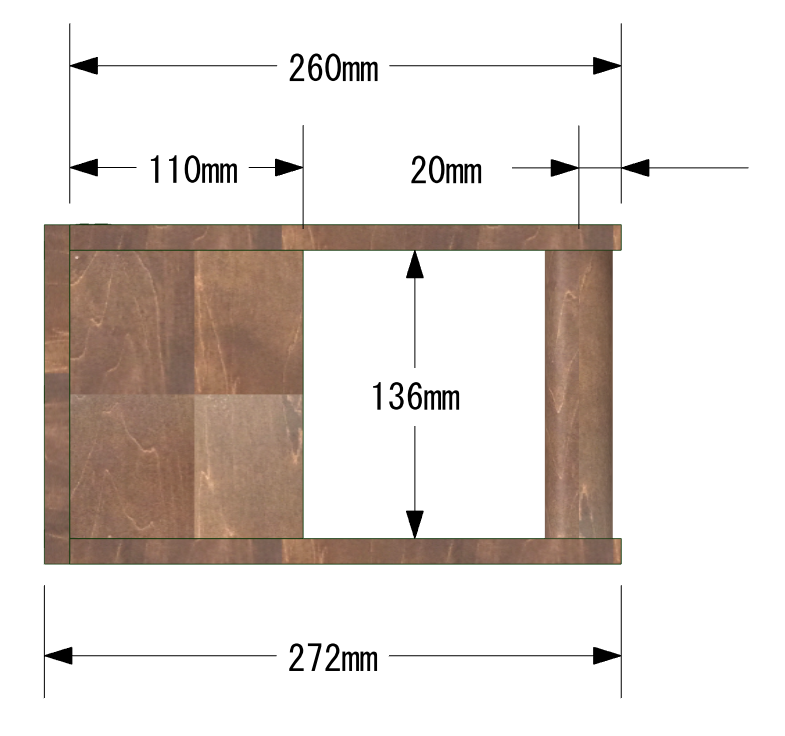

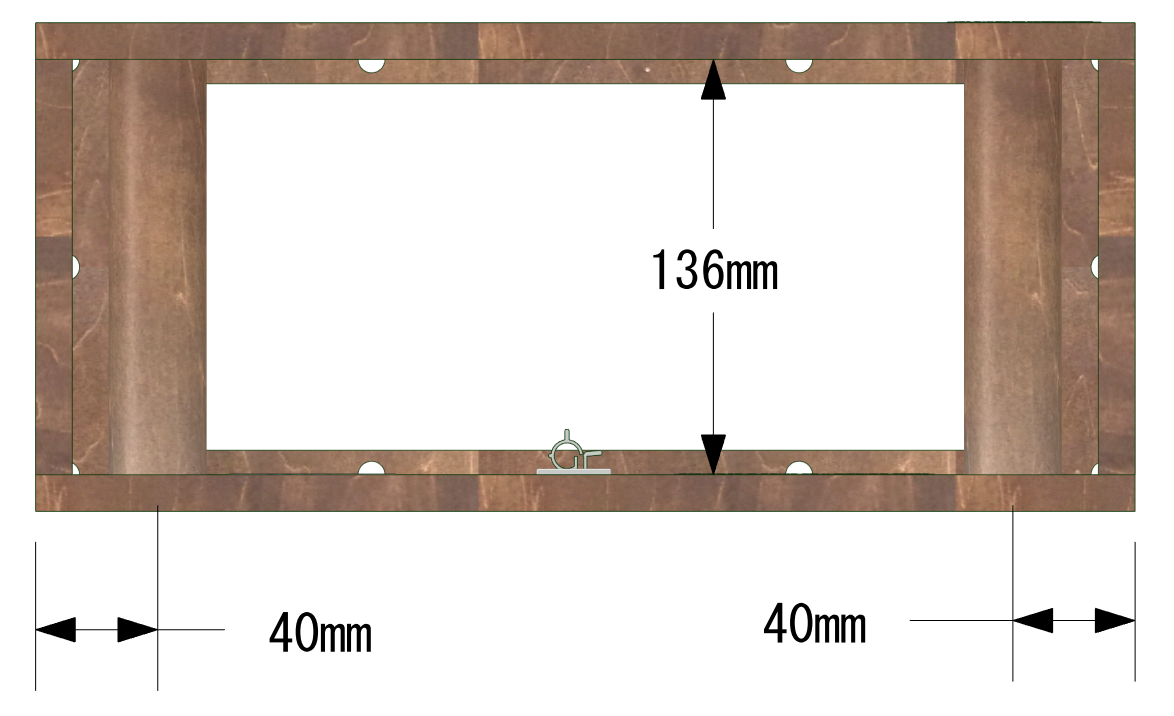

As the result of the calculation, the box volume was determined 6.9l. As for the dimension, I made the width the top priority. The width has to be the same as the woofer box, 360mm internally and 402mm externally, so that the midrange box can be integrated with the woofer box. The next priority was given to the height. The height needs to be low so that the tweeter is not too apart from the midrange. I decided the internal height is 120mm and the external one is 150mm. Automatically, the depth was calculated to be 160mm internally, and 190mm externally.

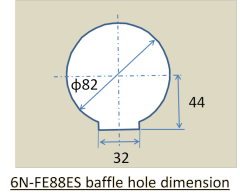

The parts of midrange boxes are cut out of the same pieces of MDF for the woofer boxes. Only the side boards are 21mm thick. The other parts are 15mm thick, the same thickness as the sub-baffles of the woofer boxes. Fostex P49 is used as the port (vent) tube after it is cut to the designed length.

The construction is the same as the woofer box. The widths of the baffle, backboard, and top and bottom boards are all 360mm that equals to the internal width. In a way, those parts look sandwiched by the side boards. The way of assembling is the same as the woofer box too. The fixed side board is put on a workbench, then the baffle, backboard, and top and bottom boards are assembled using bond on the fixed side board. After the adjustment, all the part are fixed with screws.

[Dimensional drawing of the midrange box (SS-309MidrangeBox.pdf)]

The midrange box is so small that I didn't consider installing bracing.

The baffle is two-ply like the woofer box. This is not aimed to make the frame of

the drive-unit and baffle surface flush, but to double the mass of the

baffle. The frame of 6N-FE88ES is designed so that it is simply mounted

on the baffle from the front.

Like the woofer box, the sub-baffle is screwed on the baffle, not glued.

The filling is Micron Wool, the same as the woofer box.

Many uneven wood bars are affixed to the inside of the top and bottom walls, in order for prevention of standing waves. The uneven surface diffuses acoustic waves and results in preventing standing waves from occurring. Later, I realized this method is not sufficient and an additional countermeasure is needed.

For prevention of diffraction phenomena, the edges of sub-baffle are rounded like the woofer box.

The box is assembled so that dimension errors of the parts do not appear in the front and the top of the box, just like the woofer

box.

Due to the cutting plan and the order of cutting, the baffle, backboard,

and top and bottom boards, which are sandwiched by the side boards, could

be cut out in the exactly the same width. Consequently, the kerfs that

joint the detachable side board should be flush.

To make sure, I show the cutting plan once again (the same as one in 'Design

of the woofer box').

[Cutting Plan (CuttingPlan.pdf)]

The design of the grille of the midrange box is common to that of the woofer box. The basic construction is the same, though the size is smaller.

[Drawing of the midrange grille (MidrangeGrille.pdf)]

The cable is soldered directly to the terminal of the driver and drawn out of the

box without any terminal just like the woofer box.

Building

Woodwork

I used to cut a wooden board with a saw or a power saw I rented. But, this

time, I decided to have the MDF boards cut by a professional for the first

time, because I didn't have enough space for woodwork in my condo and the

number of parts was too large for me to cut out with hand tools.

It is commonly believed that the dimension error of the parts must be 0.1mm

or less to make an exactly rectangular and air-tight box. I thought I couldn't

afford if I ordered the cut to a workshop that guarantees that precision,

so I ordered it to a do-it-yourself store in my neighborhood (the store

is closed now), where I bought the pieces of MDF.

A craftsman of the store said the tolerance was 1mm. I asked him, "Please

make the precision as high as possible, because these materials are going

to be the parts of speaker enclosures." He had craftsmanship and accepted

my request. In spite of my little worry, the dimension of the parts cut

out by him were so precise. I was relieved.

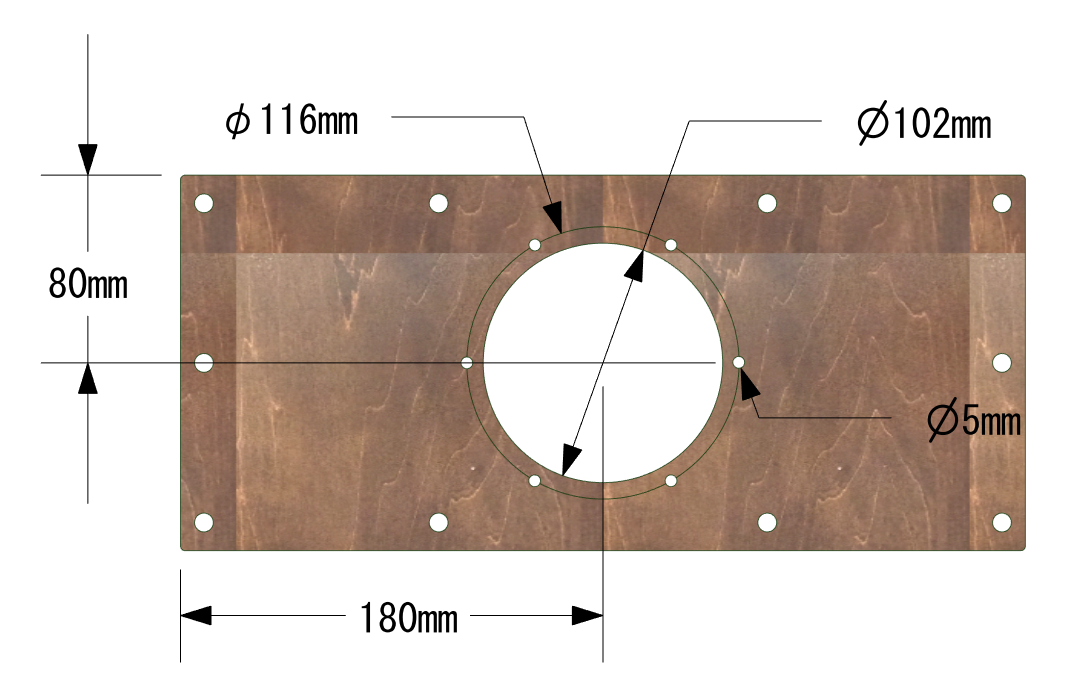

The store usually didn't accept an order of a large circular cutout like

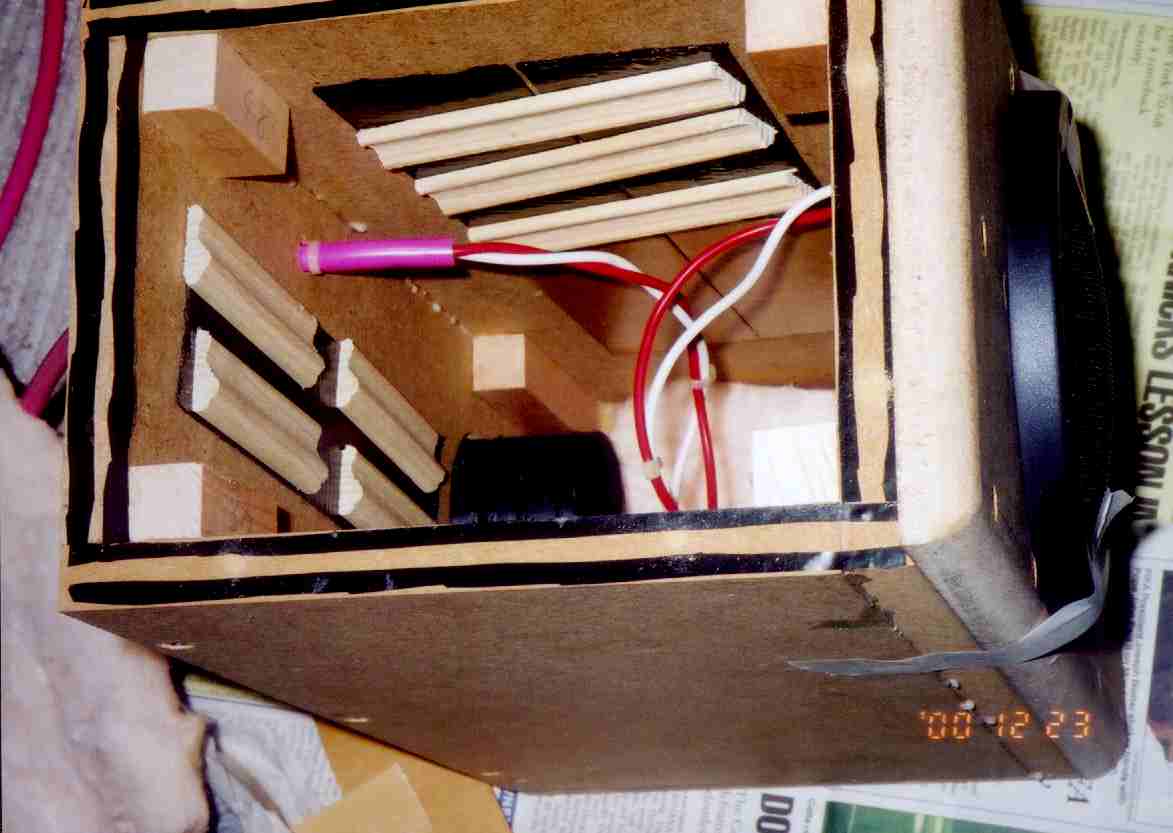

one for woofer, but the craftsman did it. The photo on right-hand side

shows the parts for the woofer boxes.

I cut out the parts for bracing and the grilles for myself.

I cut out the sub-baffle hole for the driver for myself, because the hole for 6N-FEE88ES is not a simple circular form. Since I am so clumsy, I had to concentrate keenly on the work. I managed to cut out the hole as specified in the drawing.

|

|

|

| 6N-FE88ES baffle hole dimenstion | The processed sub-baffle for the midrange box | The parts for the midrange box |

I rounded the edge of the sub-baffles with a molding plane and a special

tool I made.

The molding plane can plane the edge of the board at the angles of 30,

45 or 60 degrees.

My self-made tool is a special file to round the work with radius 15mm.

I made it by cutting a 30mm internal diameter PVC pipe for water pipe into

a handy length, cutting it vertically into two halves, and affixing sandpaper

on the inner surface of the half pipe with double-stick tape.

|

|

|

| Chamfer plane | Chamfered sub-baffle edge | Handmade tool for rounding the edges |

| Sub-baffle with rounded edges |

I drilled only prepared holes for wood screws that pass through the boards beforehand. I decided to drill prepared holes in kerfs just before screwing. I was afraid that a pair of prepared holes may be misaligned if the one in the kerf is drilled beforehand and the joint may be slid when the wood screw is tightened.

Before the assembly, I screwed a wood screw in a kerf of a leftover piece

of MDF as a trial. I found out MDF is unexpectedly vulnerable and splits

easily, although I had guessed MDF is a solid material like plastic. In

fact, it is layered like many thin cardboards are stuck. So, it is likely

to split if a thick wood screw is used or many wood screws are screwed

in the kerf.

For SS-309, wood screws are not used to fix the joints permanently, but

to fix them temporarily till the bond dries instead of cramps. So I decided

to use the minimum number of thin wood screws required to fix the joints

temporarily.

Assembly

I assembled the boxes following the procedure specified in the design phase.

Both the woofer and midrange boxes were assembled in the same procedure.

The fixed side board was put horizontally, the baffle, backboard, and top and bottom boards were put vertically on it, and the parts were glued each other with wood

bond. Bond was applied plenty so that, in case that a slit occurs at a

joint, the bond will fill it. Bracing was glued in each corner between

all walls of the woofer box. By the way, the bond I used was a commonly-used

type, not a quick-drying type.

While the bond was still wet, each part was adjusted in position to make

the front and top surfaces flush.

After the positions of all parts were fixed, screw holes were drilled in

the kerfs by inserting the bit of an electric drill into the prepared holes

that had been drilled beforehand. This work needed an extra care not to

move the parts.

Each wood screw was not tightened individually. First, all the screws were

screwed halfway. Then, in order to keep the joints from sliding, one screw

was tightened a little with a screwdriver (not an electric screwdriver),

then another was tightened in the same way, and so on, till all the joints

were secured. Finally, all the screws were tightened firmly with an electric

screwdriver.

The above process must be done quickly before the bond dries. When the work was done, a lot of bond leaked out of the joints. I left it as it was.

When the bond became adhesive, I turned over the box with care not to slide the fixed side board. Then I screwed it on the box. Now the box was rigid.

Next, the sound deadeners were fixed with wood bond and wood screws.

Then, the detachable side board was going to be screwed. Because the dimensional errors were so small,

the kerfs were flush. I decided to use insulating tape instead of rubber

sheets to keep the box air-tight. The tape is cheaper and easier to use.

The tape was affixed on the kerfs and small holes were cut out at the positions

of the prepared holes for the wood screws. The detachable board was screwed,

and the box had all six walls at last.

Finally, the box was completed by fixing the sub-baffle on the baffle. The sub-baffle is fixed with only wood screws. Bond was not used.

The frames of the grilles were made of the 18mm square spruce bars, which was the same material

as the bracing of the woofer boxes. Fast-drying type of wood bond is used

to assemble them, and neither wood screws nor nails are not used.

The net was stapled on the frame after it was cut into a piece of an appropriate

size.

Finally, the grille holders (male part) were screwed on the frame. The

grille was completed.

|

|

|

Because the female part of the grille holders were going to be attached to the sub-baffles, the prepared holes were drilled in the sub-baffles. Besides, the prepared holes for the insert nuts for a Fostex genuine grille were drilled on the sub-baffles of the woofer boxes too.

Finish

First of all, I cut off the bond sticking out of the joints with a cutter.

I applied putty on the heads of the wood screws that would never be removed.

After the putty got dry, I sanded a little the outer surfaces of the boxes

with an electric drill with a circular sandpaper attached.

Now, it was time to paint the boxes. I made a temporary workroom by using cardboards on the balcony

of my condo, where I painted them.

Soon I realized that it is very difficult to spray varnish evenly. Even

though I did my best, the sprayed varnish became uneven. But, this uneven

varnish looked terrific like oil stain paint. So I continued to spray the

varnish. The color of the varnish was maple, and if it's painted on MDF,

the color became rather reddish. I was attracted to this color too. I sprayed

the baffle four times, and its appearance became so cool (the other surfaces

were painted three times).

I affixed instant lettering to read my brand name (NOBODY) and the model number (SS-309), then sprayed clear varnish three times. This finished the paint work.

The heads of the wood screws that would possibly be removed (not covered with putty) were painted metallic dark gray for better appearance.

Mouting theDrive-Units and Other Small Parts

The female parts of the grille holders were hammered into the prepared holes on the baffles after varnish was completely dried. On the baffles of the woofer boxes, the insert nuts for the Fostex genuine grilles were hammered in too.

Because the port tube for the woofer box, Tritec BR-70, is a simple plastic tube, it needed

to be deadened. It was rapped with a 0.1t brass sheet and cloth tape on

it.

The tube was mounted on a small MDF board to form a port assy. The port

assy was screwed to the backboard. Since it is detachable, it is easy to

replace the port.

The port tube for the midrange box, Fostex P49, was cut to be 60mm long

(the inner diameter is 49mm). It is mounted on the backboard with double-faced

adhesive tape.

|

|

| Deadened port tubes | Port assy mounted on woofer box |

The last step was installing the drive-units and the filling. The detachable side boards were removed temporarily.

The drive-units were all removed from SS-307, and the cables remained soldered to the drivers' terminals. I mounted the drivers on

the baffle with wood screws, after I made the cables pass through the holes

for the cable. At that time, I was very careful so that I won't damage

the drivers with the tip of the screw driver.

The diameters of the holes for the cables were matched to the external

diameters of the cables, so that it is not necessary to seal the holes

with putty.

I lined the filling, not filled, since both the woofer and midrange boxes are bass reflex type.

By the way, I mounted the drivers and ports to the midrange boxes temporarily before I painted the boxes, and played music for adjustment of the filling. Then, I removed the drivers and ports, and painted the boxes.

|

Completed baffle of woofer box |

|

|

| |

| Completed woofer box (front) (photo taken in 2009) |

Completed woofer box (back) (photo taken in 2013) |

Woofer box w/ grille |

Woofer box w/ Fostex grille |

|

|

|

| Completed midrange box (front) | Completed midrange box (back) | Midrange box w/ grille |

Installation and Tuning

Tuning of the midrange module preceded painting. The driver, port and filling were installed temporarily.

I set up the midrange module as a full-range speaker, and played various

kinds of music. Its crystal-clear sound was so impressive that I can never

forget it. The tonal quality was totally different from SS-307. I keenly

felt that different enclosures have so different tone even with the same

driver.

When I listened very carefully, I felt a bit unpleasant echo, and supposed

that it was resulted from standing wave in the box. I came up with a countermeasure;

I crumpled up a piece of Micron Wool into a ball, tied it with a string

and hanged it from the top wall of the box.

This countermeasure was more effective than expected. It made the sound

clearer furthermore. This midrange module was the the finest one-way speaker

I had ever heard, if its poor bass response could be neglected.

I didn't care much about bass response, since this midrange module would

be used mainly as the midrange speaker. And the driver 6N-FE88ES was designed

for a backload horn system, so I accepted a certain level of non-flatness

in the bass response. As a result, the bass response was not bad, except

for poor deep bass response. The upper bass response was so good.

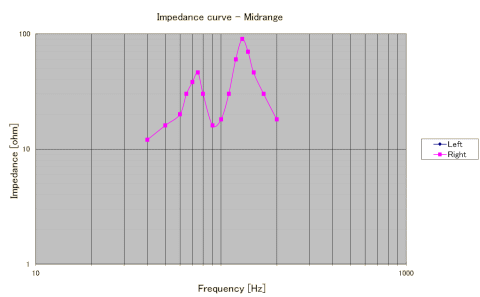

I couldn't measure the characteristic, as I didn't have required measurement

instruments and environment. The only data I could measure was impedance

vs frequency response. The curve had two peaks, which is typical for a

vented-box.

Although I was once satisfied with the midrange module from the bottom

of my heart, I was disappointed later. It was painting that slightly lowered

the sound quality. After painting the enclosure, I set up the midrange

module the same as the first trial listening. I played various kinds of

music again. The sound was no longer as clear as it had been.

I hadn't known the fact that painting influences tonal quality. The influence

might be significant particularly to sound-absorbing materials like MDF.

I suppose the painting makes the surface solid like plastic, and that increases

unwanted radiation from the enclosure.

I tried affixing a piece of felt to the surface of the baffle in order to absorb the unwanted radiation. But it didn't work. On the contrary, it worsened sound quality. I had to remove the felt for the better result. At that time, the surface layer of the varnish was removed too. The appearance got worse.

Later, I found an article in IPSJ (Information Processing Society of Japan)

Magazine that focused on the relation between tone of musical instruments

and their measured data. The article showed an interesting example; one

craftsman make two identical violins; the only difference between them

is varnish; these violins have different tones to human, though their characteristics

measured by the best measurement instrument are the exactly the same.

It is necessary to study the relation between the enclosure finish and

tonal quality furthermore.

I determined the amount of filling by intuition and lined it on the inner

walls of the woofer boxes. Soon I set up the woofer modules as full-range speakers. The first impression was very good. I said to

myself, "It's perfect!" I really felt so without any concrete

grounds. Therefore, I decided to use them as they were without any actual

tuning.

I have been using the woofer modules without tuning since then, though

I once replaced the port with a shorter one to boost bass. After all, I

replaced the port back with the original one. As of August 2013, I still

use them in the initial setting. I don't feel like tuning them, because

I am afraid that I would spoil these perfect woofer modules if I change

anything about them.

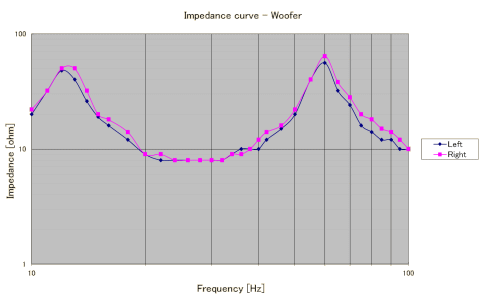

The impedance vs frequency response of the woofer modules were nearly ideal curves with two peaks. The Helmholtz Frequency fb was approximately 26Hz. The response was extended down to the 25Hz band at full level.

At last, it was time to install SS-309. I placed the woofer modules where the pair of SS-307 were installed (the corner of the living room of my condo). The speaker bases of SS-307 were reused. They were merely old magazines put on the floor. They were pressed by the weight of the speaker system and made flat and solid. Since a pile of papers is a good sound absorber, it might be an ideal speaker base.

A vibration proof rubber mat was put on the woofer module, the midrange

module was placed on it, and the tweeter module on the midrange module.

The midrange module was designed asymmetry. It was placed so that the driver

was positioned near the center of the system. The tweeter was placed just

above the midrange driver. The tweeter module was composed of the tweeter

T925 and a stand that came with T925. A vibration proof rubber was affixed

to the bottom of the stand.

The speaker systems were toed in a little.

|

Positions of the drivers The R-ch unit: Midrage driver is positioned near the left end of the eonclosure. The tweeter is positioned above the midrage driver. |

The configuration of the amplifiers remained unchanged. The setting of the network CD-206 was also unchanged. The crossover frequencies were 800Hz and 8000Hz.

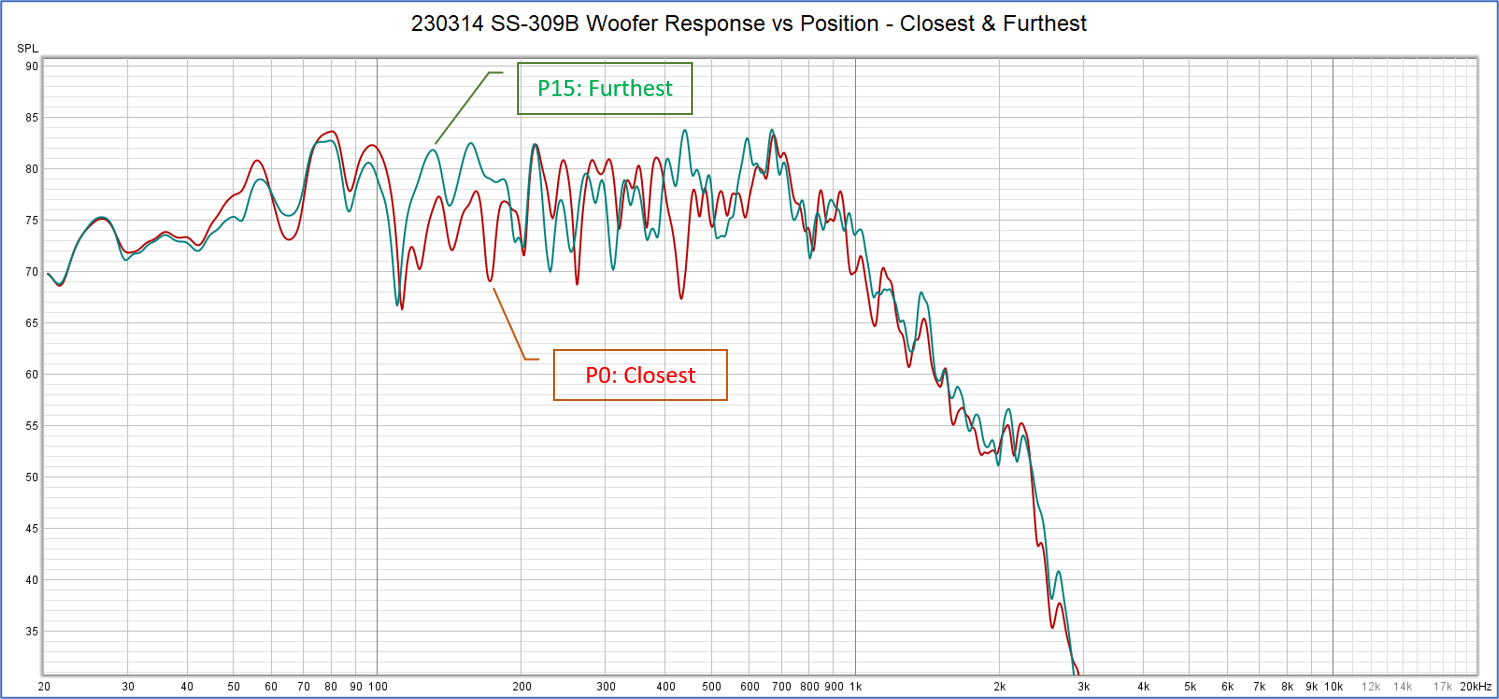

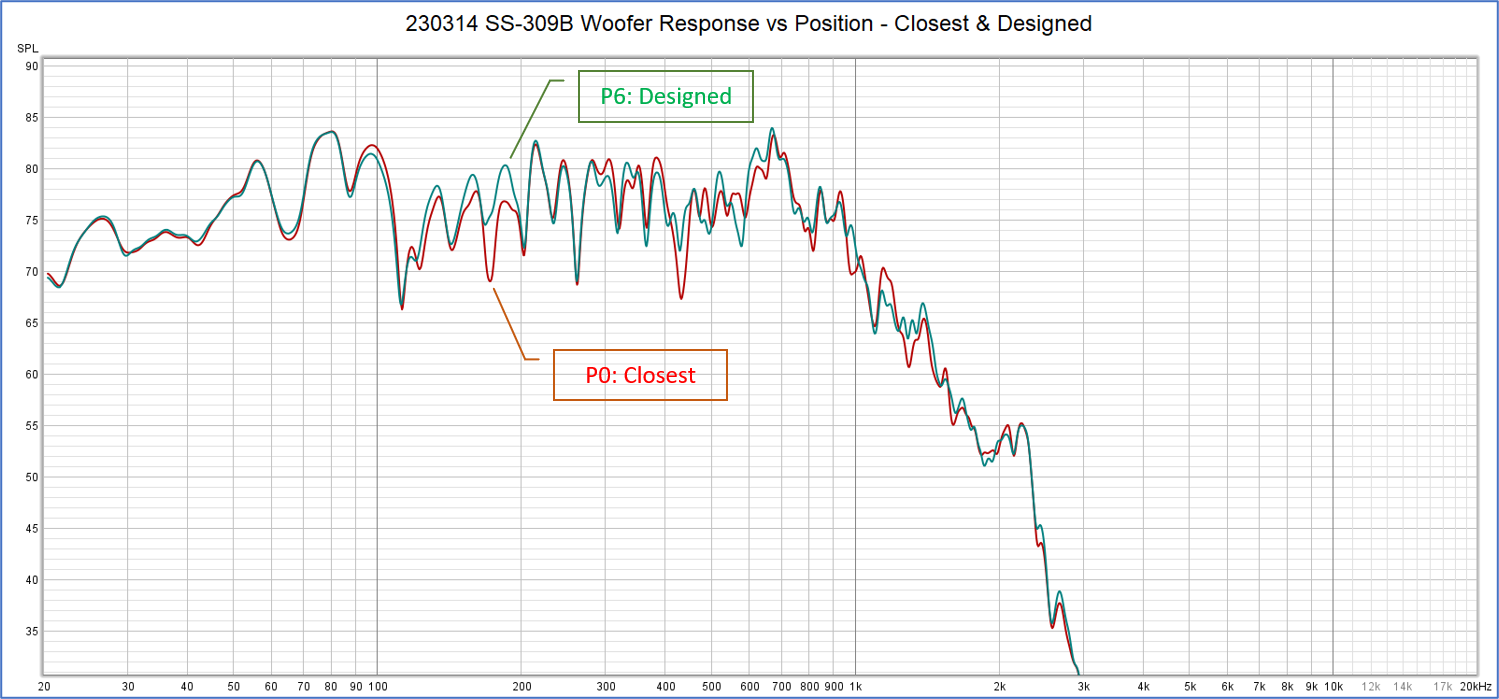

A loudspeaker sounds differently according to its position in the room.

Especially, bass response is greatly influenced by the distances from the

boundaries of the room. But I couldn't choose the best position because

my room was not spacious. I had no option but to place the SS-309s at the

corners of the room; each speaker was placed 20cm from the wall behind

it and 10cm from its respective sidewall.

The bass was boosted and sounded so rich. But it was not unpleasantly boomy

bass. I liked this rich and pleasant bass.

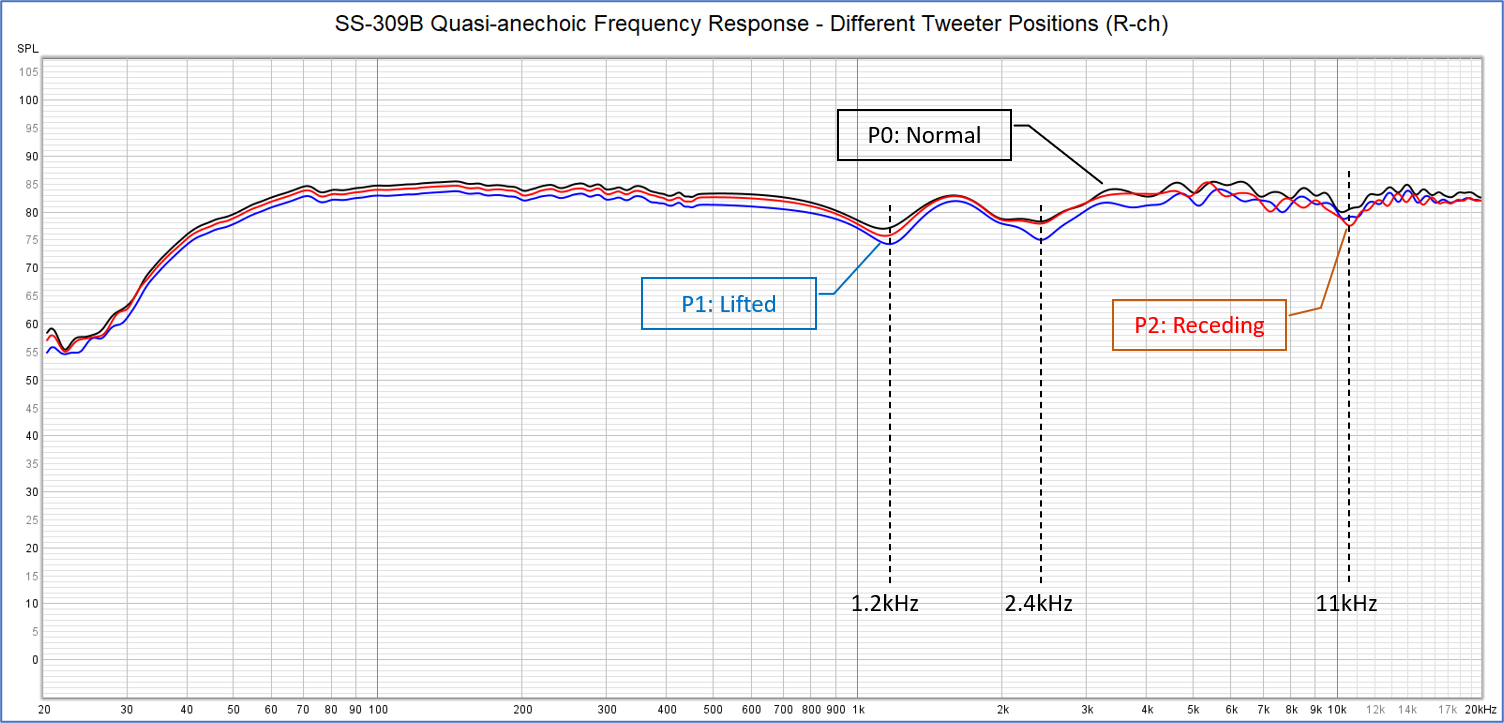

It took me a lot of time and labor to adjust the position of the tweeter back and forth. The crossover was 8000Hz, and the wave length at the frequency is about 43mm. If the tweeter was moved by 21mm (the half of the wave length) back or forth, the phase difference between the tweeter and the midrange would be 180 degrees, and the tone would change significantly. While playing music, I moved the tweeter little by little until the sound became the most natural.

The photo on the right side shows SS-309 (R-channel) just after the installation. (June 2001)

My Own Review

Looks

The main purpose of this project was make good-looking loudspeakers. I

flattered myself that the purpose was achieved. My wife, too, admitted

that, and said, "It's OK to install them in the living room."

She hates naked loudspeakers (the drive-units are not covered with the

grilles). On the contrary, I feel SS-309 looks good without the grilles.

Besides, the grilles slightly impair sound quality.

Sound Quality

The woofer FW305 delivered its potential performance compared with SS-307. It exhibits

good transient response at low frequencies. It was so brisk that I felt

so good when I heard the sound of a bass in jazz. Though the volume of

bass was high, it was not pushy, and sounds of low-pitched instruments

were never exaggerated.

In addition, the woofer module can produce deep bass that is felt more

than heard and dynamic bass like rambling of the earth. For example, the

sound of a big taiko drum of Ondekoza (its fundamental frequency is 28Hz)

made me feel so good (CD, Ondekoza, Ondekoza (I), Victor VICG-5373). I

felt a wind pressure radiated from the taiko drum, and the realistic sound

made me feel as if I had been listening to a real live performance. And,

when the scene of launching the rocket in the movie APOLLO 13 was played

(DVD, APOLLO 13, SUD-29954), I really felt rambling of the earth. I thought

SS-309's ability of reproducing deep sound favorably compared with a movie

theater's public address system.

Though FW305 does not employ any novel mechanism nor special materials,

I love it. I like a simple, back-to-basics audio parts like FW305. I would

like to keep using it as long as possible.

The midrange module offered pretty high quality in midrange and upper midrange, though painting

had slightly impaired the clarity of the sound. For most full-range drivers,

treble is rolled off at a relatively low frequency, or trebles are distorted,

so it's better to add a tweeter in many cases. But trebles of 6N-FE88ES

were so good that I even thought it could be used as a tweeter.

Although full-range drivers perform very well when they are used as a full-range

driver, they tend to lower the system's total sound quality when used as

a midrange driver, because their performance are not as good as the woofer

and tweeter. But 6N-FE88ES was excellent as a midrange driver too. I believed

that's because its performance from upper midrange to treble is so good

that it could be used as a tweeter.

When the midrange module is used as a midrange speaker, the bass reflex

port should be stuffed up. The rear of the diaphragm emits the same sound

pressure as the front of the diaphragm in opposite phase. The sound leaks

from the port and interferes with the sound from the front. This distorts

midrange sounds in particular. Although the midrange module sounds so good

when it is used as a full-range speaker, when it is used as a midrange

speaker with the port open, its sound quality is not as good as the tweeter

and woofer because of the distortion. So the port should be stuffed up

in order to balance its tonal quality with the tweeter and woofer.

I had expected closing the port would not be necessary because SS-309 had

employed the rear port system. But it was necessary after all against my

expectation. I decided to stuff up the port with a rolled urethane mat

when the midrange module is used as the midrange speaker, though it is

a little troublesome.

The midrange module can be switched to the full-range speaker in Gaudi

(and vice versa). In that case, it is used with the port open. That is,

it works as the bass reflex system.

I have been using the tweeter T925 since 1982. I don't think it has deteriorated by aging yet, and still have confidence in it. It is a super tweeter rather than a tweeter, so I set the crossover to 8,000Hz. Although it reproduces only upper treble, T925 contributes a lot to the system's overall sound quality . It greatly affects not only treble but nuance of midrange and bass. SS-309's high quality of bass sounds is resulted from not only the high performance of the woofer but also that of T925.

User-friendliness

SS-312 is compact and floor-standing type. It's easy to install it. I think

the book-shelf type is rather difficult to install.

SS-312's lower body functions both as a stand and a CD/DVD rack. It is

more convenient than I expected.

I think SS-312 is a user-friendly speaker.

Summing Up

I think I've got the intended results. SS-312 is a good speaker system

to enjoy background music at my leisure time.

Its construction is simple, and no special technique is needed to build

it. It's recommendable for easy-going DIY audio.

This tweeter's most attractive feature is its capability to offer the texture of the sound source (instruments and voices). For example, it reproduces sounds of cymbals in jazz not as mere, rhythmical treble sounds but sounds produced by hitting a heavy metal disc. T925 sounds as if you could see the instrument. I would like to use it until its life will end.

Low directivity is known as the shortcoming of horn tweeters. But, on the

contrary, I take it to be an advantage. A horn tweeter can deliver acoustic

energy toward the listener's ears with a least loss. I believe this fact

is deeply related to the above-mentioned sound quality that makes the listener

feel the texture of instruments and voices.

A dome tweeter, which has high directivity, cannot offer enough acoustic

energy directly to the listener, and a fair amount of sound is reflected

by the boundaries and reaches the listener indirectly. Indirect sounds

become beautiful echoes in a very large room like a concert hall, because

the indirect sounds significantly delay to reach the listener. But in domestic

rooms, the time difference between the direct and indirect sounds is so

small that the sound may be heard distorted and/or the sound image may

be blurred.

I firmly believe that horn tweeters excel dome tweeters, unless the room

is very spacious or the walls and ceiling are made of sound absorbing materials.

So far, I reviewed each module. It is a tough question to evaluate SS-309

as a whole. SS-309 is composed of the self-contained modules, and it is

not a complete speaker system until combined with the network and power

amplifiers.

Compared with SS-307, I thought SS-309 was at much higher grade. SS-309

sounded more vividly. Especially, sounds of brass instruments were remarkably

lifelike, maybe because the tweeter was horn-loaded. In addition, I felt

SS-309 could reproduce very low level sounds so precisely. I realized I

almost achieved my goal: dynamic, vivid, yet precise sound.

Usability

The speaker cables are soldered directly to the terminals of the drive-units except the tweeters, so it takes a lot of labor to change the cable. It

is a weak point, in terms of usability. However, in the world of audio,

it happens quite often that high usability worsens sound quality. This

is the case. Through my long experience, I know (a) contact(s) between

the power amp output and drive-unit blurs the sound. I believe the direct

soldering is the best solution in spite of its low usability.

And, experience shows that if a cheap cable and an excellent cable are

connected in series, the sound quality will turn to be the same as the

cheap one only. In the future, a more excellent cable may be invented.

If only the external cable is replaced with the new cable, it will not

bring about a good result. The internal cable is also to be replaced with

the new one. As for SS-309, the cables directly connect the power amps

and the drive-units. There is no distinction: 'internal' and 'external'.

When the cable is replaced, it means the entire cable (both the internal

and external cables) is replaced. This makes it sure to maximize the performance

of the new cable.

When I was designing SS-309, I already had a plan to move to a single-family

house. So I designed the woofer box so that the Fostex genuine grille could

be attached. The grille was made of metal and so rigid. It was so useful

when we moved.

I bought Fostex genuine grilles for 6N-FE88ES too. It was attached to the

midrange box with adhesive tape. The box itself wasn't designed to attach

the genuine grille.

Summing up

I think I have achieved the goals for both the appearance and sound quality.

I feel Gaudi got another step closer to the high-end audio system.

However, Gaudi hasn't exactly conformed to the original system design yet.

The full-range units are used in the midrange modules as substitutes of

midrange units. Even though a full-range unit sounds good in its original

usage, in general, it is inferior to midrange units when used as a midrange

driver. The same thing applies to SS-309. The performance of 6N-FE88ES

is apparently insufficient compared with FW305 and T925. It is desirable

to upgrade the midrange modules as soon as possible (as described below,

I upgraded the midrange modules by changing the drive-units to horn-loaded

midrange units at last in 2012).

Improvements

Move to my new house (May 2003)

My new house is a well-insulated, air-tight, two-story wooden house. Though

it is not particularly constructed soundproofed, its thermal insulator

and double-paned glass in the windows excel in soundproofing too.

The living room, where Gaudi is supposed to be installed, is located at

the north end of the second floor unlike ordinary houses. There is no attic

above the living room, so the ceiling is high and slanting. Because sound

has the property of going upward, the high ceiling reduces the distortion

caused by reflection. In addition, the slanting ceiling prevents standing

waves from occurring, since it is not parallel with the floor.

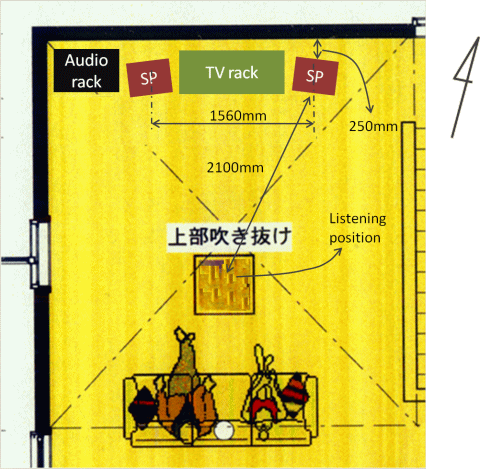

The living room is designed so that Gaudi is installed against the north

wall, which has no window. I put each SS-309 250mm away from the north

wall and distant from its respective side walls (see the figure below).

The distance between the speakers is not long (1560mm). I wanted to put

them more distant from each other, but I had to compromise because the

room is the living room and a TV set is also installed there.

The listening position is 2.1m away from each speaker. The distance is relatively short, though, it is desirable because the percentage of reflection from the boundaries in the total of sounds the listener hears is kept low. And, there is a large space behind the listening position. This is also desirable for a good sound quality.

I spent much time and effort to adjust the distance between the speakers

and the wall behind them, because it is an important factor for the volume

of bass sounds. In practice, however, the volume didn't vary much according

to the change of the distance. The volume was always a little short.

The low frequencies might not be reflected by the wall but go through it,

because the inner side of the wall is made of ordinary plaster boards.

And, I've heard that bass sounds of a rear-vented speaker is not boosted

even if the speaker is near the wall behind it.

I attempted to boost bass by shortening the port (130mm->113mm). This

countermeasure was a little effective, but not enough. I took another measure

at a later date.

I thought using old magazines as a speaker base is not suitable for the

brand-new house, and decided to use a piece of carpet and four bricks for

each speaker. This resulted in the obviously worse sound quality than the

old magazines. I knew bricks are so easy to resonate.

I planned to add spikes under the speaker enclosure to reduce the resonance.

I looked for good spikes at an audio shop where I was a regular customer,

and chose Dali's spike set because it was reasonable and the height was

adjustable.

The spikes improved sound quality to some extent, compared with putting

the speakers directly on the bricks, but I was still not satisfied. Spikes

may not be so effective to prevent vibration from propagating as their

claims. [2015/01/27 corrected] {I used the spikes in a wrong way. For further details, see 'Correct use

of the spikes (Nov. 2013)'}

Improvement of the speaker base (Nov. 2004)

I considered using heavier objects instead of the bricks. I looked for

a shop that sell stones in Rakuten Ichiba (http://www.rakuten.co.jp/) and

found a good shop that cuts stones like granite and marble stones according

to the customer's plan at reasonable prices. The shop was MG Sekigahara

(http://www.rakuten.co.jp/mgs/). I ordered two granite boards of which

dimension was 20x401x390mm. The total price was about 8,500 yen.

The granite board is rather heavy, so it acts as a mechanical earth. It

improved sound quality. I felt the speaker became able to offer higher-resolution

sound.

|

Improved speaker base From the bottom, a piece of nylon carpet, 20t granite board and DALI spikes. A piece of filling (Micron Wool) is placed between the enclosure and the granite board. |

I considered changing the insulator between the woofer and midrange boxes

from the vibration absorbing rubber mat to spikes too. But spikes are so

large that the gap between the woofer and midrange boxes becomes rather

wide. I decided to use a substitute.

I found an interesting information on Internet that a 10-yen coin is a

good insulator. I tried it out soon. It was true. It improved sound quality

a little. I tried out a 100-yen coin too. It was not as good as the 10-yen

coin. I experienced such a thing many times that the more expensive an

audio accessary is, the poorer sound quality is.

I used the 10-yen coin insulator for some months, but I re-considered it

and reached a conclusion that the point contact is better than the surface

contact. I decided to use small pointy stones. I picked up about 20 small

stones that are all the same in size from my graveled backyard. Then, I

selected two quads of the stones that make the midrange box not shaky.

I put each quad under each midrange box's four bottom corners. This led

to better sound quality, and I was satisfied at last.

|

|

|

Upgrade of crossover network (Feb. 2005)

I upgraded the crossover network from CD-206 to CD-211 A-NET.

The lower crossover of CD-206 was 800Hz (18dB/oct) and the upper one was

8000Hz (12dB/oct). As for CD-211, they were 720Hz (18dB/oct) and 7200Hz

(18dB/oct), respectively. The filter for the tweeter cut off more rapidly

below fc. This reduced the current flowing the tweeter voice coil below

fc, and improved clarity of treble. The potential performance of T925 was

successfully drawn out.

I used CD-211 in that setting for a while. One day, I found a bump at the

fc region between the woofer and midrange bands, and I decided to change

the characteristic of the filters. I changed the -3dB cutoff frequency

of the woofer filters from 720Hz to 530Hz, whilst the lower cutoff of the

midrange filter remained unchanged (720Hz). The attenuation at fc became

-6dB. The continuity from the upper bass to the lower midrange was much

improved, so that SS-309 played sounds neutrally as if it had been a one-way

speaker.

In theory, the attenuation at fc should be -3dB in order to flatten the

system frequency response. But the bump would be developed unless the midrange

unit is separated from the woofer by a large spacing.

Upgrade of the speaker cable (Sept. 2009)

As for the speaker cable, I tried out various types of many manufacturers

since I built SS-307. But I didn't think any one of them was obviously

superior to others. Though each manufacturer's catalogue or something like

that said how excellent their products were with many plausible advertising

statements, I felt they were sort of extravagant advertisement. I began

believing a simpler cable was better than high-tech cables these days just

like amplifiers.

One day, I looked at the web site of Oyaide Denki (an Akihabara-based cable

vendor, http://oyaide.com/catalog/) and was attracted to a 0.4mm solid

wire manufactured by 47 Laboratory (http://www.47labs.co.jp/). In fact,

I knew the wire a long time before, and had e-mailed an inquiry about it

to Oyaide. At that time, I judged it was not good because it was made of

very cheap materials. This time, I was attracted because most of the user

reviews about it gave it five-star praise, and decided to employ this simplest

wire. FYI, the conductor is tough pitch copper without plating and the

sheath is 1mm-thick polyethylene. No other material is used. So simple!

All the speaker cables were replaced with the new ones. However, I chose

0.65mm solid wire for the woofer cables, because the 0.4mm wire has a little

too high resistance and that may reduce the damping of the woofer. The

low damping makes bass sounds boomy.

I bought the wires online from Oyaide. The price of the 0.4mm solid wire

was 273 yen per meter, the 0.65mm was 315 yen (for the simplest wires,

the prices were not so cheap, were they?).

I made the speaker cable by twisting the two wires at 30cm (1 foot) pitch.

The end of the wires was only stripped because they were going to be soldered

to the terminals. The only exception was the end that was going to be connected

to the midrange amp Flying Mole DAD-M100Pro. Because this amp's terminals

were unable to be soldered, I decided to attach banana plugs to the end

of the cable that was connected to this amp. A special banana plug for

the 0.4mm wire was available from 47 Laboratory. I bought four of the plugs

for the cable.

This plug is designed based on a seemingly crazy idea; contacting the wire

core directly to the terminal of equipment. The plug is made of Delrin

and hollow to insert the wire in it. The tiny hole is bored at the tip

of the plug to draw out the wire core through it. The wire core is bent

180 degrees and looped around the part of the plug that is inserted into

the terminal. Inserting the plug makes the wire core contact the metal

part of the terminal directly.

I realized this plastic plug had several problems. First, bending the wire

core 180 degrees produces unwanted inductance and some of the current is

reflected at the bending point. Those lead to distortion of the signal.

Second, since the wire core is not plated, it corrodes rapidly even at

room temperature. And, the terminal of DAD-M100Pro is plated with nickel.

Contacting different metals accelerate corrosion. Third, the dimension

accuracy of this product is so low. One of the plugs was a little too thick

and could hardly be inserted into the terminal. Another one was so thin

that it was not secured in the terminal and came out easily.

In spite of these problems, I used the plastic plugs for a few months.

When one of the plugs became faulty because of corrosion of the wire core,

I stopped using the plugs. I am so disappointed since the plug was not

cheap (483 yen at Oyaide). I used banana plugs for measurement instruments,

instead. Though it was cheaper than the plastic plug by far, it excelled

the plastic plug in sound quality. I experienced that again, "The

more expensive an audio accessary is, the worse its sound quality is."

[2015/02/14 added] {I stopped using the banana plugs. The cable cores are directly connected

to the terminals now. Wako Technical Titan Audio Oil are applied to the

cable cores to prevent them from corroding}

I read an explanation on 47 Laboratory's Web site that cables were so vulnerable

to vibration. At that time, I didn't think speaker cables were so microphonic,

because they conducted large signals and microphonic noise was too minute

to negatively affect sound quality. But, as a trial, I followed 47 Lab's

recommendation; hanging the cables in midair to prevent vibration. The

speaker cable I made weighed only a dozen grams or so per meter, so hanging

it was easy. I fitted up hooks on the wall near the ceiling, hanged strings

from the hooks, and hanged the speaker cables with the strings. For the

parts of the cables that inevitably touched the floor or the speaker enclosures

I put vibration proof rubber mats beneath them.

This method was more effective than expected. The grade of sound rose one

step higher. I really felt Gaudi sound was approaching that of high-end

audio further.

|

|

Gaudi was successfully upgraded. It was proved that my motto, "the

best is simple," was applied to speaker cables too. In addition, it

came to light that the following theory was not right; the thicker the

cable core is, the better sound quality is.

I guess too thick cable core distorts the signal, because its surface area

is so large that high frequency currents that flows the surface due to

skin effect causes eddy current and produces distortion in treble band.

It is often said that a thin speaker cable does not conduct deep bass.

The same opinion was written in the homepage of 47 Laboratory too. However,

I don't feel Gaudi cannot reproduce deep bass after the speaker cables

were changed. I believe the theory that reproduction of deep bass needs

a thick cable is a superstition. Perhaps, the fact that to produce bass

sounds by playing a stringed instrument the thick string is used leads

to this superstition.

In practice, a thin cable makes deep bass boosted, because its relatively

high resistance weakens damping of the woofer just like using a power amplifier

with low damping factor.

Renewal of the woofers (Oct. 2009)

The surrounds of the woofers were broken due to aging. I had to repair

them.

I checked up Koizumi Musen's Web site (http://www.koizumi-musen.com/),

and found that fortunately FW305 was still in production and available

on the Web site. I decided to buy new FW305s instead of repairing the surrounds,

because I was anxious about the result of the repair. Besides, the new

drivers would extend the life of SS-309. I think Fostex Company should

be praised for it produces products like FW305, which are excellent in

spite of the old designs, continually for long term.

The price was raised compared with the old FW305. I bought the old ones

also at the Koizumi Musen, a loudspeaker shop at Akihabara district, and

the price was about 18,000 yen per unit, if I remember correctly. The new

one's price was about 22,000 yen. But I was convinced when I saw the new

FW305 for the first time. The many parts, at least visible ones from outside,

like the frame, surround and terminals were improved.

After replacing the drivers, I realized sound quality was apparently improved.

What I did can be said to be upgrade rather than a mere repair.

I replaced the port back with the original one (68mm-diameter x 130mm-long) after the new FW305s were well broken in.

Installation of acoustic panels (Sept. 2012)

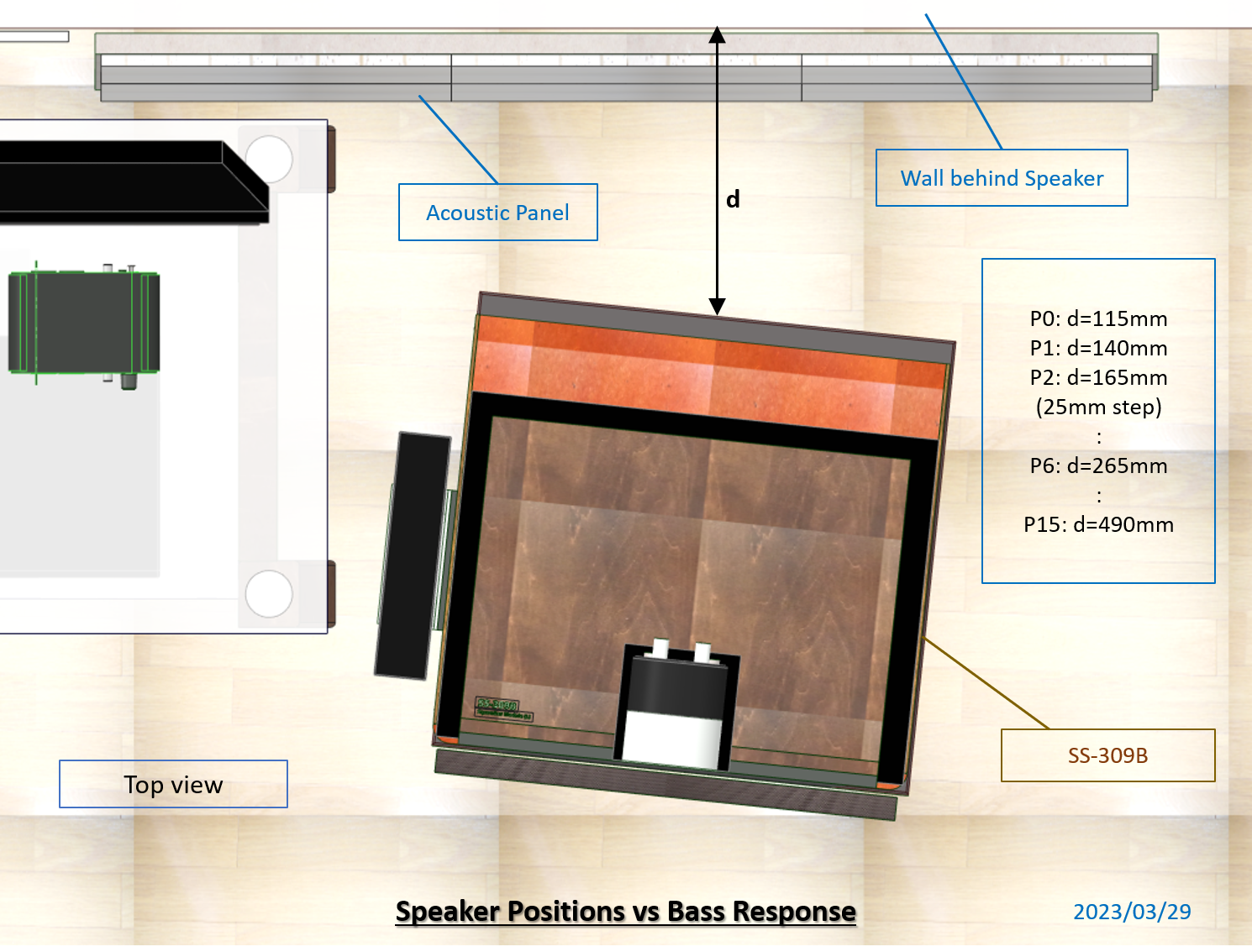

Though I was satisfied with the volume of bass sounds when SS-309 played very loud, I was a bit dissatisfied at normal listening volumes. The interior wall behind the speakers is an ordinary one and made of 12.5mm thick plasterboards with wall paper on them. It reflects mid to high frequencies while gets low frequencies through it. To solve the problem, I hit upon an idea of making acoustic panels that absorbs mid to high frequencies and reflects low frequencies, and installing them behind the speakers.

The base was a 18x1220x910mm MDF board. Sound absorbing boards made of

rock wool (Yoshino Gypsum (http://yoshino-gypsum.com/en/index.html) Solaton

Cube Cross 6T) were nailed on it.

The acoustic panels were installed as they leaned against the wall behind

the speakers.

|

|

|

These acoustic panels improved not only bass response but also stereoimaging. Before that, sound localization tended to lean to the left-hand side. But now the localization was more accurate.

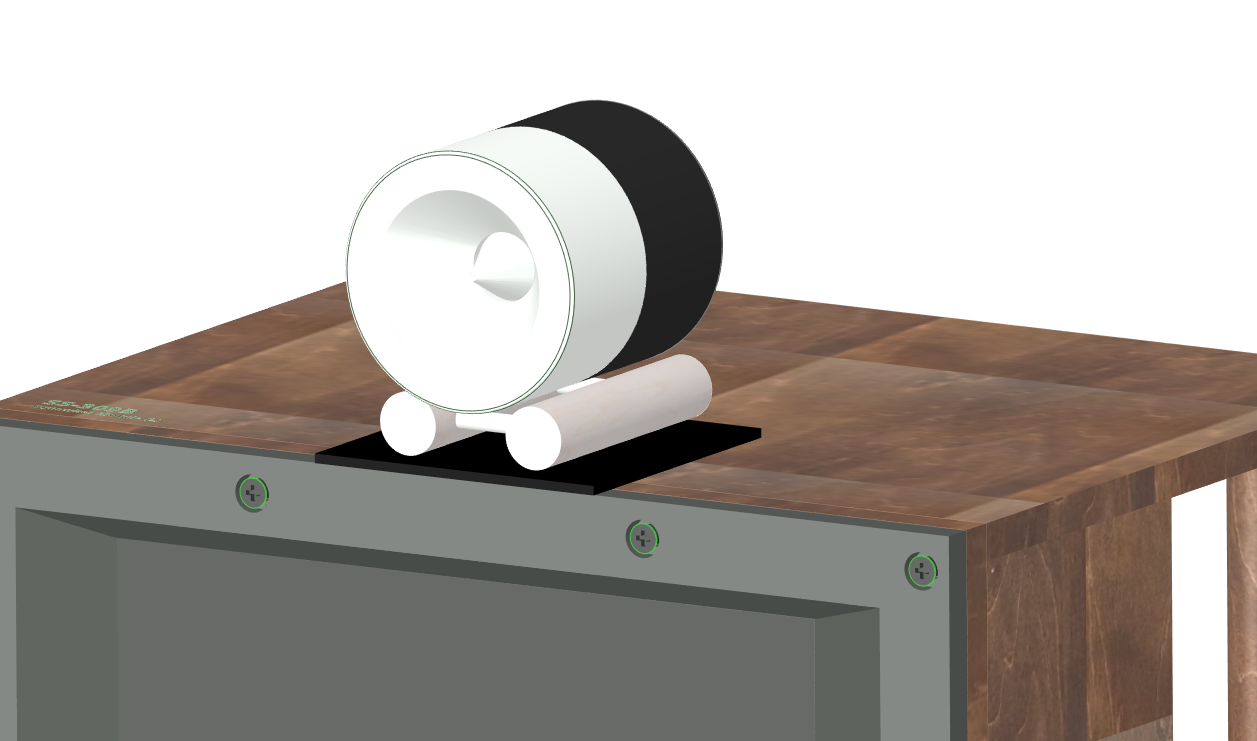

Rev. A: Upgrade of the midrange module (Nov. 2012)

Finally, the time came to replace the midrange modules with horn-loaded drivers. It was the time the loudspeaker system I had considered as the ideal since 1974, when I was 17 years old, became reality.

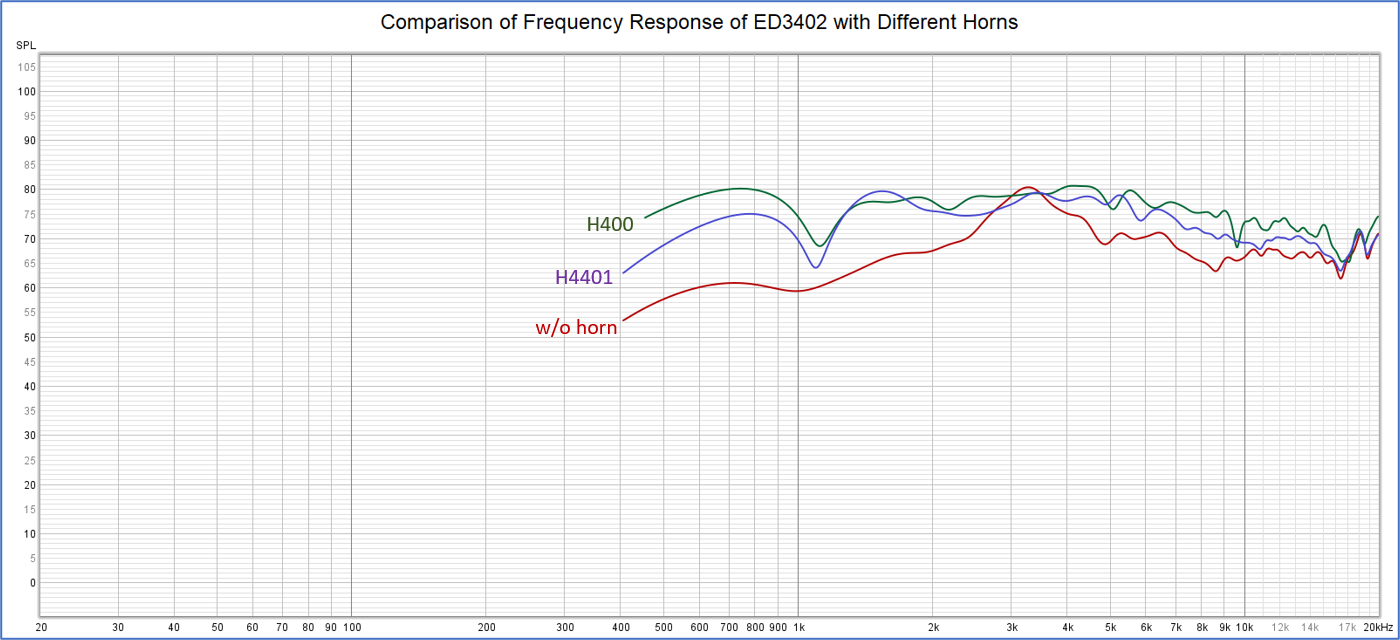

The LS units I employed were Fostex H400 wood horn and Fostex D1405 driver. These were the LS units I had already chosen when I designed SS-309.

|

|

|

|

The two pairs of H400 and D1405 cost me about 180,000 yen. It was very unusual decision for me, who don't like spending much money for audio, to buy such expensive audio components. The point is that I believed (now still believe) the loudspeaker dominates the system's overall sound quality and the midrange unit is the most influential component in the speaker system. My theory is, "The midrange unit determines sound quality, and the tweeter determines tone." I think it is a waste of money to spend much money for power amplifiers, because they are less influential in the system's overall sound quality. In the audio system, it is the midrange unit that is really worth a high price.

The recommended crossover frequency fc of D1405 was 850Hz or higher, but

the lower cutoff frequency of the midrange filter of the network CD-211 A-NET was 720Hz. I customized CD-211 to change the cutoff to 880Hz,

and that of the woofer filter from 530Hz to 720Hz.

CD-211 had two more features to be customized.

One was adding attenuators to the midrange outputs. The gain of the midrange

amp, Flying Mole DAD-M100Pro, was so high that the signal had to be attenuated

quite a bit with the input attenuator. Until then, the attenuation was

about -20dB. The sensitivity of 6N-FE88ES was 90dB/W(@1m), whilst that

of D1405 was 104dB/W. The attenuation had to be increased by 14dB, but

the maximum attenuation of DAD-M100Pro's input attenuator was -30dB. Therefore,

I added the attenuators to the midrange outputs. The attenuation was fixed

to -20dB.

The other one was a functional change. Until then, the midrange outputs

of CD-211 was switchable from midrange to full-range, and vice versa. Adding

full-range signals possibly damages D1405, so I customized the function

so that the outputs are switchable from midrange to midrange + treble,

and vice versa. When the switch on the front panel is set to '3-way', 880-7200Hz

band is output from the midrange outputs. When the switch is set to '2-way',

frequencies above 880Hz are output.

It took a lot of time and labor to customize CD-211. Though it was Oct. 2011 when I bought D1405s and H400s, they couldn't be installed till Nov. 2012, when the customize was completed and the suffix A is added to the model number (CD-211A).

I had one more thing to do before installing the wood horns. There was a possibility that leakage flux from the driver's strong magnet adversely affects the pickup of the analog disc player PS-104. To prevent this, I attached a magnetic shield board made of Permalloy to the audio rack.

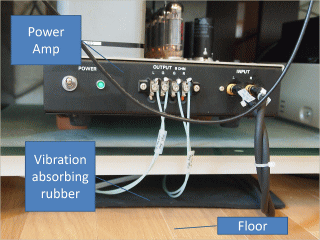

The installation of the horns itself was easy. First, I screwed the drivers to the horns. Then, I put vibration proof rubber sheets on the woofer boxes and the midrange horns on them. On the midrange horns I placed the tweeter modules. Finally, I made cables with 47 Laboratory 0.4mm solid wires, and connected the midrange drivers to the power amplifiers, Flying Mole DAD-M100Pro.

|

|

(Nov. 2012) |

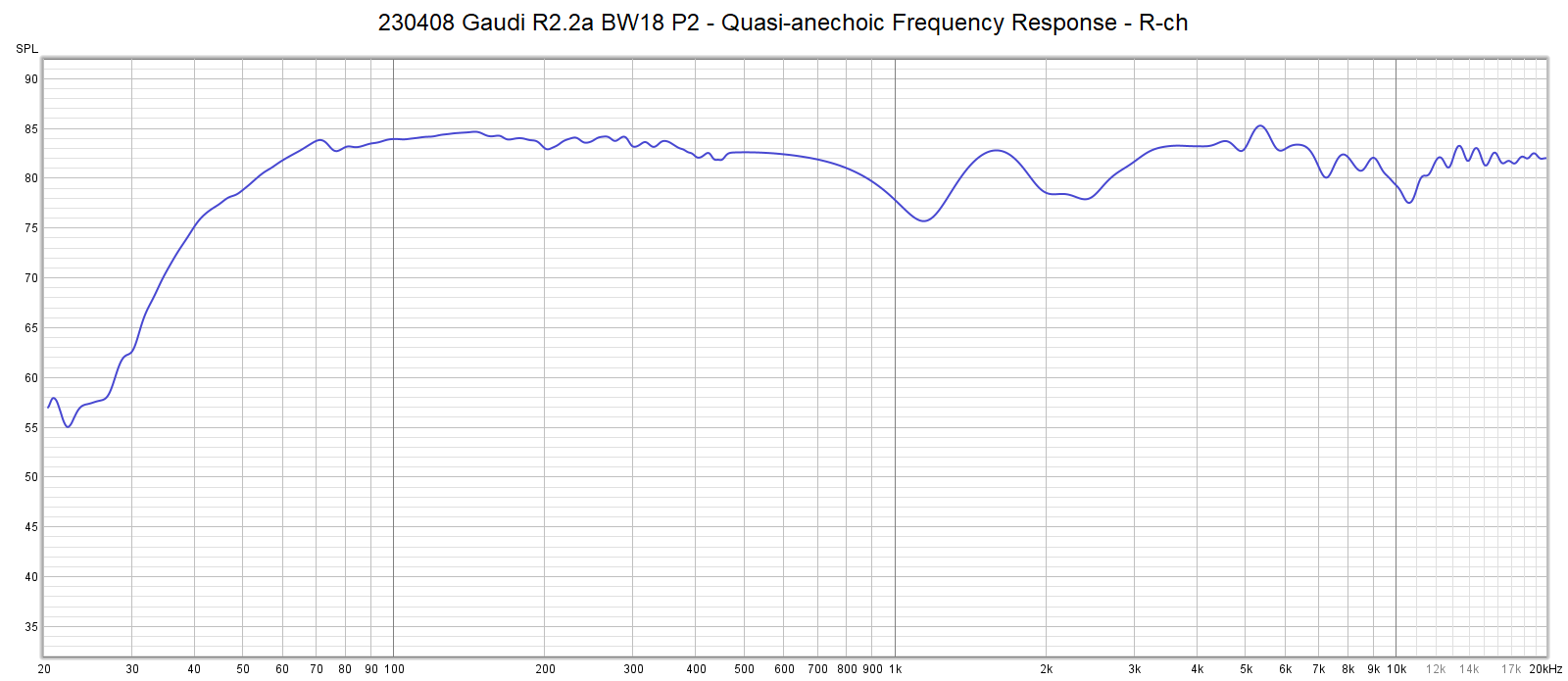

The tuning of the speakers was less troublesome than expected.

First of all, I adjusted the level of each drivers. While playing a test

CD that contains sine waves of ISO recommendation 2661/3 octave frequencies

(20Hz, 25Hz, 31.5Hz, ..., 16kHz, 20kHz), I measured the relative SPL with

a microphone (audio-technica AT-822) and an IC recorder (TASCAM DR-1) and

adjusted the levels to flatten the frequency response. Next, while playing

various kinds of music, I fine-tuned the levels such that they sounded

maximally natural to my ears. It took me about one week to achieve a satisfactory

result.

When 6N-FE88ES was used as the midrange driver, the adjustment of the levels

was a very troublesome task. The method using a microphone and a VU meter

was unreliable. The only dependable measurement instrument was my ears.

It took me a month or two to tune the speakers those days (see 'Tuning').

At the end, I adjusted the position of the horns in front-back direction.

It was unexpectedly easy too. But there's a possibility that the horns

are still not placed at the best position due to my lax adjustment.

As for the point of interest, which is sound quality of course, I got as good a result as I had expected.

My first impression was, "Beautiful!". Beauty has been added

to Gaudi sound that was attractive thanks to its vibrancy and vividness.

Especially, harmony of strings or chorus is breathtakingly beautiful so

that I am entranced with the music without knowing. For example, the sound

of cascading strings performed by Mantovani (CD, Mantovani Orchestra, Mantovani,

Encore!!, Victor VICP-5618) is so beautiful that it makes me filled with

a feeling of happiness. Of course, not only strings but every kind of musical

instruments such as wood winds, brass winds and the percussion sound better

than before. I feel their sounds became more precise and lifelike.

I had been anxious that the sound might become a little 'honky' colored, but I realized it was a pointless concern. And, though I had been worried that sound quality wouldn't be good until the drivers were aged enough, it was a needless concern, too. I felt the new midrange drivers sounded okay from the beginning just like the new FW305s installed in 2009. Fostex might ship its products after aging them enough in its factory.

One more thing I noticed is that the quality of bass sounds has been improved.

Although the woofer modules and their related components haven't been changed

at all, bass sounds became more dynamic and clearer. Unlike typical commercial

loudspeakers of which bass character is intentionally boosted and boomy,

SS-309A reproduces comfortably sharp and lean bass sounds. Though they

are dynamic, they do not sound exaggerated but precise and realistic. The

sound of a wood bass in jazz music are so realistic that I feel like I

were listening to a live performance.

Another merit of SS-309A that deserves special mention is clarity of both

speaking and singing voices. It is so easy to catch lyrics of songs. As

for English songs, the pronunciation is heard so clearly that I can catch

the meaning of the lyrics without effort. I often find myself immersed

in a world an English lyric depicts insomuch that I forget the lyric is

written in English without realizing. Now Gaudi is the best hi-fi system

I've ever heard when it comes to ease of catching lyrics.

I think it was a wise decision to employ the horn-loaded drivers. The horn-loaded

driver can reproduce minute sounds precisely because its ultra light diaphragm

and voice coil are driven by the very strong magnetic circuit. And it also

can play super-loud with ease because the horn drastically increases the

efficiency with which electrical power is converted into acoustic power.

Its high sensitivity reduces the burden of the power amplifier and speaker

cable, and makes it possible to simplify them.

Nowadays horns are largely disappeared from domestic audio use, though,

I believe they deserve to be revalued.

This upgrade resulted in a big success, but one problem was revealed; residual noise comes from the midrange. It includes susurrus

that is nearly pink noise and 'gee, gee, gee, ...' noise that might be

harmonic components of hum noise.

I was surprised because the specification of the midrange amp, Flying Mole

DAD-M100pro, is excellent (SNR:120dB, residual noise:25uV, etc).

The sound of piano is so realistic, but when I listen to it very carefully,

I feel its lingering sound is a bit dull. This might be an adverse effect

of the residual noise. [2015/01/26 corrected] {I found out later that this was caused by the lack of break-in of D1405.

Noises, which are components not relating to the signal, doesn't make the

sound dull. The real cause is distortion, which is deformation of the signal}

If the noise includes hum, it may damage the midrange drivers. I observed

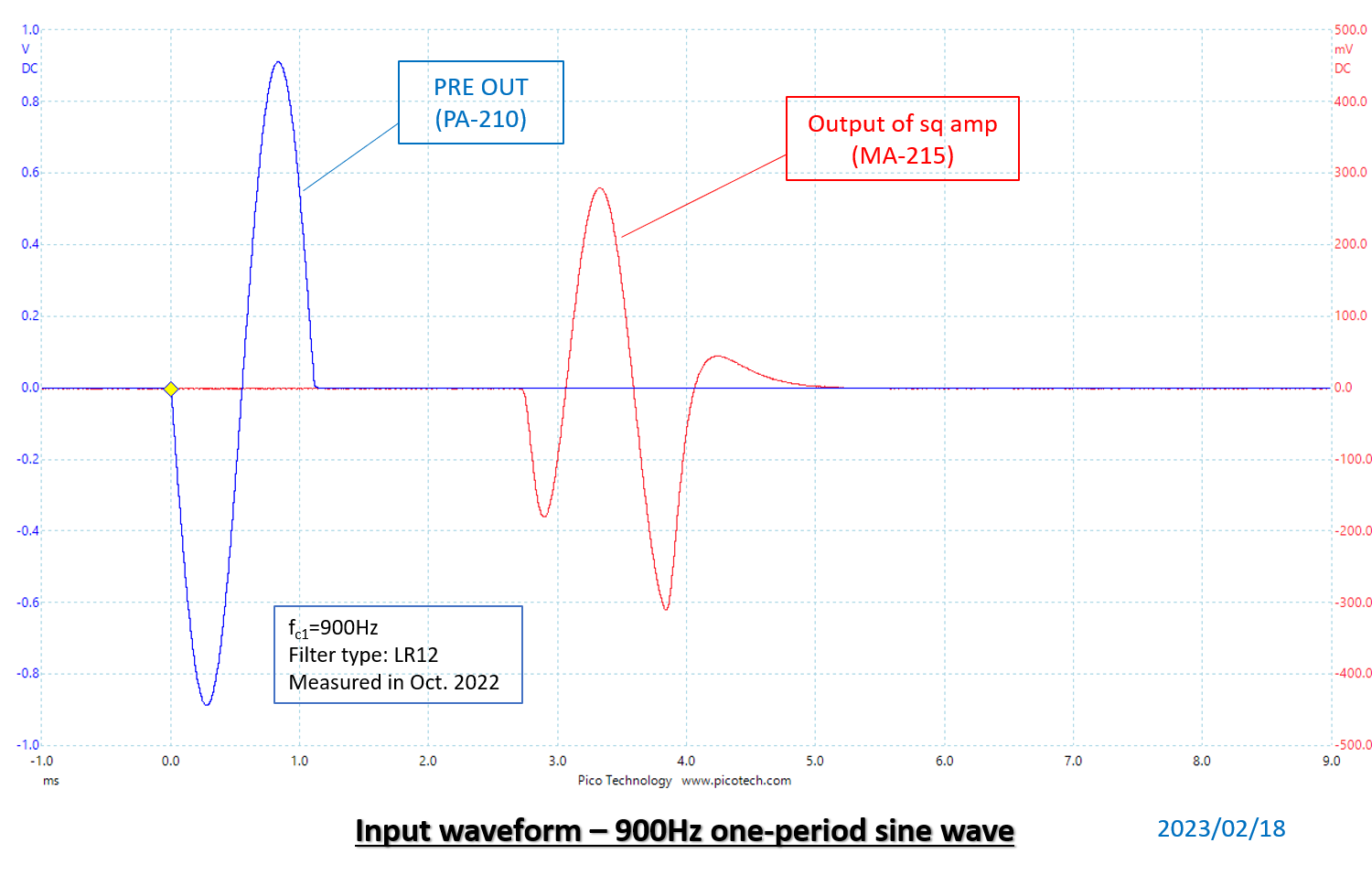

the waveform and frequency spectrum of the residual noise with the instrument

(PicoScope 6) at once. I did it with the input of the power amp short to

ground and the output connected to the driver D1405.

The peak frequency was 393kHz and the level is 171mVrms. Probably, it is

the clock frequency of DAD-M100Pro. The noise level in the audioband was

quite low in spite of my concern. Hum was not found. The noise level is

so low that it won't possibly damage the drivers, but it is surely a problem

not to be overlooked.

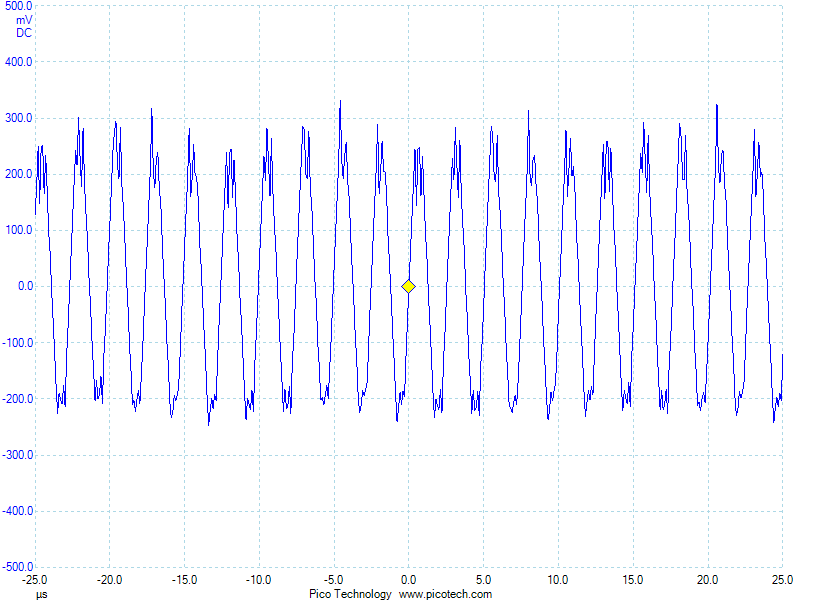

|

Waveform of the residual noise |

|

Frequency spectrum of the residual noise |

I consulted some books and learned that the problem is not unique to DAD-M100Pro

but common to all class-D amplifiers. The conclusion is that class-D amplifiers

shouldn't be connected directly to horn-loaded drivers.

Class-D amplifiers have a passive (inductor/capacitor) low-pass filter

between the final stage and the output terminal in order to cut off frequencies

above the audioband (RF). But the passive filter cannot eliminate RF to

zero. A small amount of RF, especially the clock frequency of the amplifier,

pass through the filter as shown in the figure above. The direct radiator

won't convert RF into acoustic wave, because its moving parts such as the

diaphragm and voice coil are too heavy to respond it. In contrast, the

horn driver's moving parts are vibrated by RF, and RF is modulated to audible

frequencies. So the noise is heard.

For example, the user's manual of Rasteme RDA-560, a 6-channel class-D

amplifier for tri-amplified audio system, includes a caution that says

the amp may generate white noise or damage the driver, if it is a horn-loaded

super tweeter (FYI, I heard Rasteme went bankrupt).

The midrange amp must be a linear amp. After all, I already had a plan to design and construct a new midrange amplifier, MA-215 Arabesque. I made up my mind to give the first priority to MA-215 and suspend the construction of a headphone amplifier HA-213 and the design of a phono equalizer PE-114 Petit. Of course, MA-215 will be an ultra low noise linear amplifier.

Correction of the Use of the Spikes (Nov. 2013)

[2015/01/27 added]

The spike without the pedestalI noticed that pedestals that came with the

Dali's spikes were still placed under the spikes. They are needed when

the loudspeakers are installed directly on the floor. They are not needed

for SS-309 because it is installed on the stone board. But they are placed

under the spikes since November 2004 (see 'Improvement of the speaker base

(Nov. 2004)').

Using these pedestals spoils the effect of the spike (reflection of vibration).

The vibration of the speaker used to propagate to the floor such that I

felt the vibration with my fingers when the speaker played very loud and

I touched the floor in front of the speaker.

I noticed this mistake at last, and removed the pedestals. The photo on

the right-hand side shows the removed pedestal behind the spike. The vibration

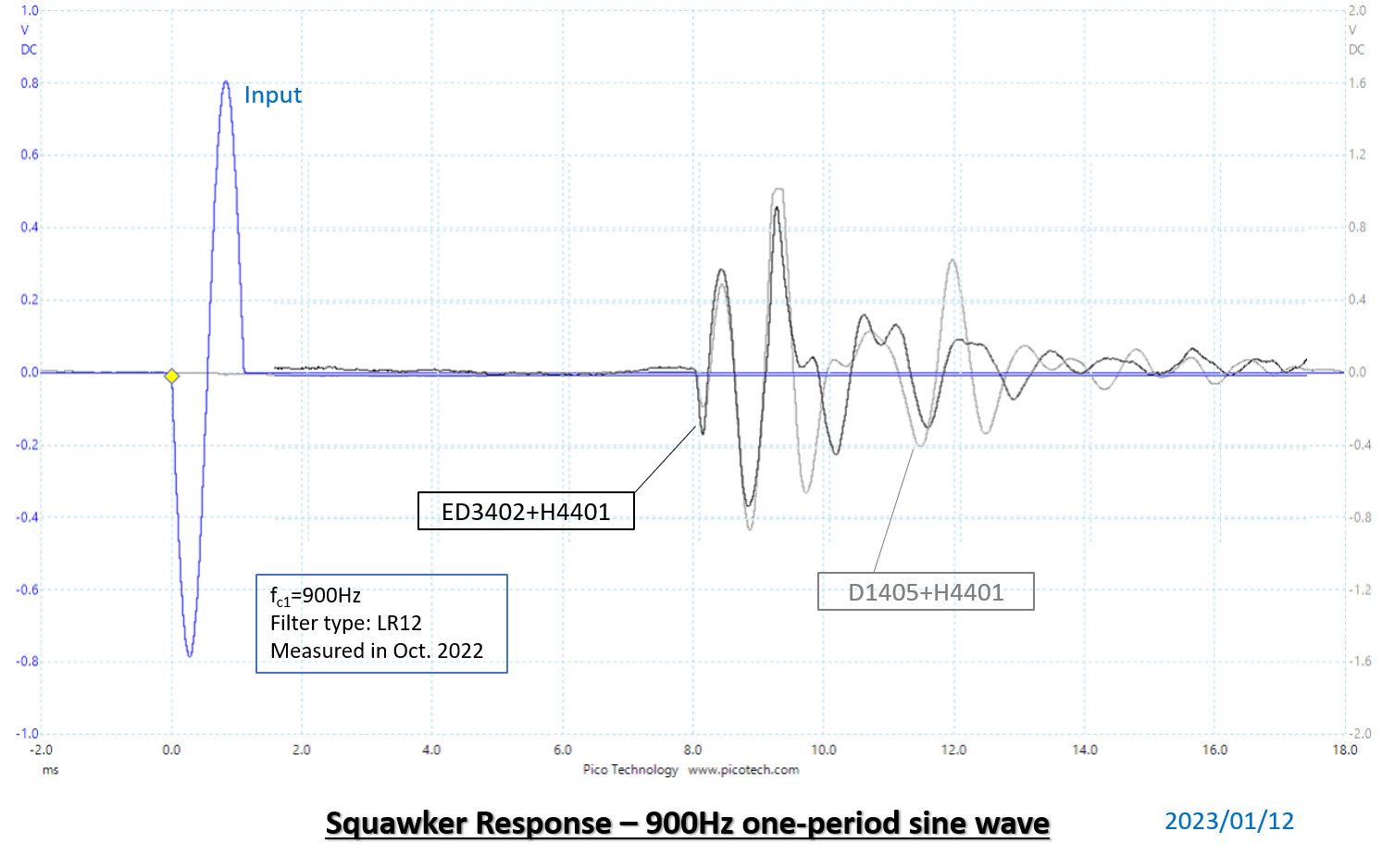

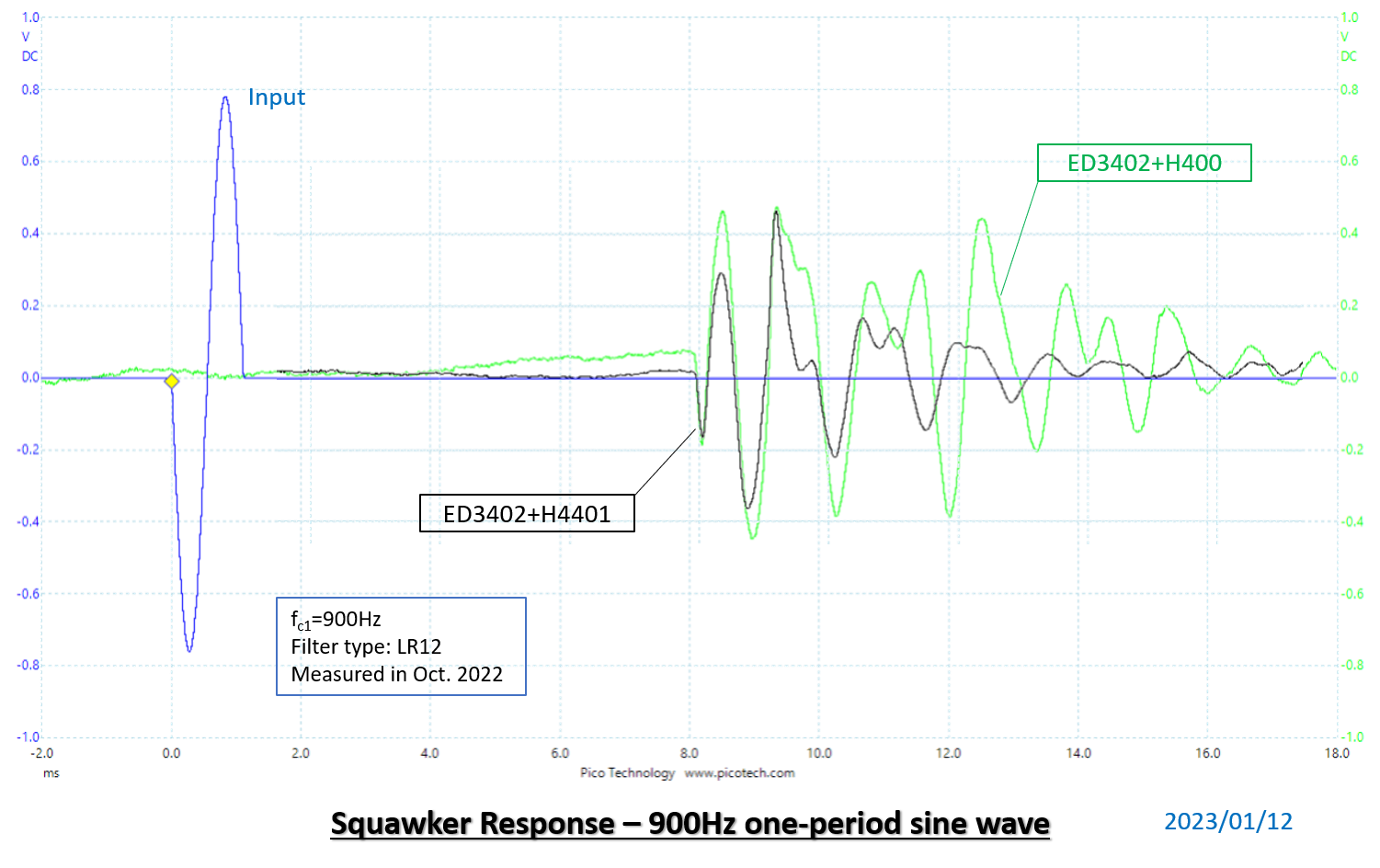

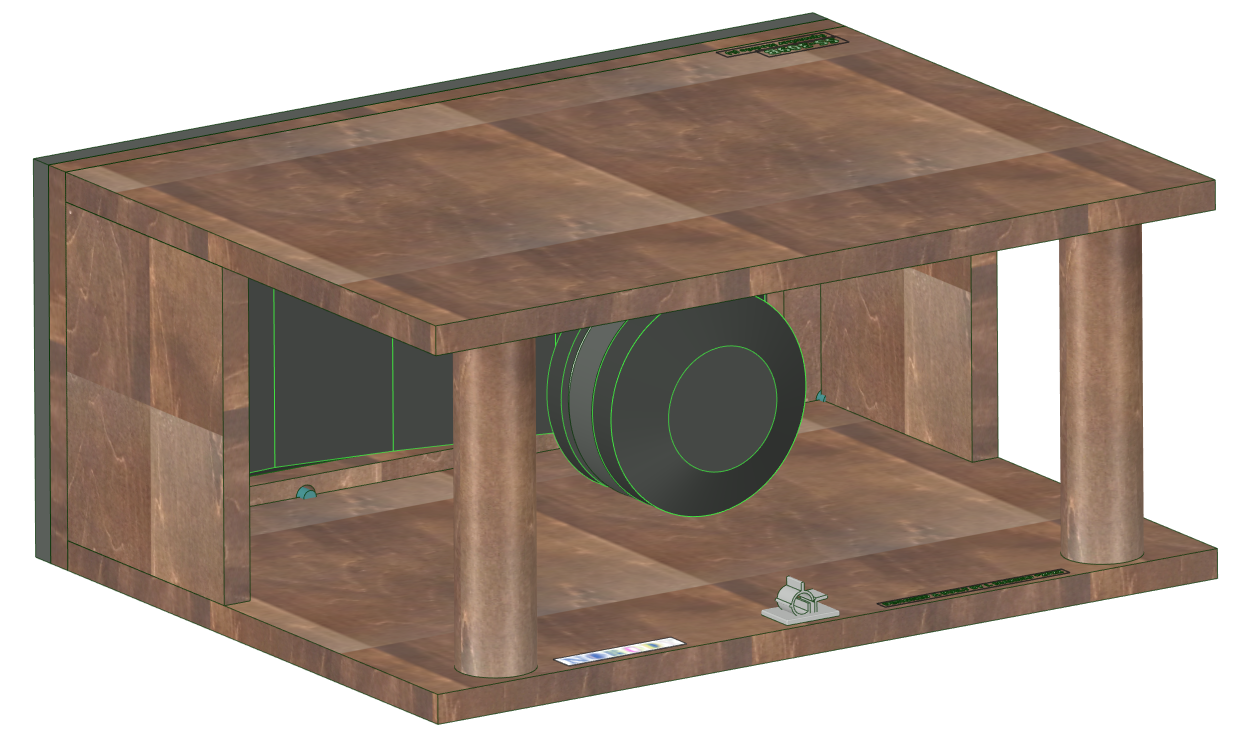

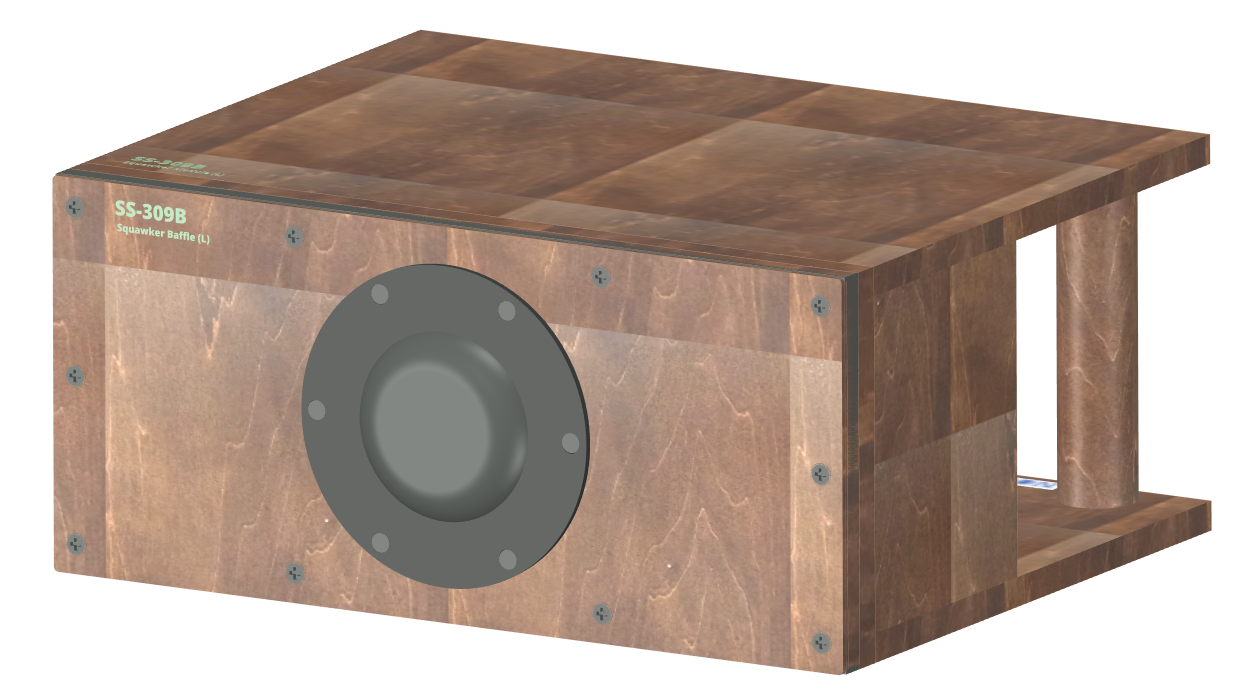

of the floor significantly reduced.